Welded Wire Mesh for Building -1/2 X 1/2

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Welded Wire Mesh

Welded Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire, PVC coated iron wire in blue, green, yellow and other colors.

Application of Welded Wire Mesh

Galvanized welded wire mesh, PVC coated welded wire mesh for garden, feeding agriculture, fishing, poultry, mine field, lawn cultivation, and profession’s guard, decorate machine protection. Special welded wire mesh, (Heavy)welded wire mesh panel service as fencing mesh for transportation industry, construction a agriculture.

Surface treatment of of Welded Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Pvc coated welded wire mesh, (black wire mesh then pvc coated, electro gal. then pvc coated, hot dip gal. the pvc coated)

Advantage of Welded Wire Mesh

Our welded wire mesh has strong corrosion-resisting and oxidation-resisting with good quality and rock bottom price.

Packing of Welded Wire Mesh

1. Waterproof paper then PVC shrinking Film

2. PVC shrinking film only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

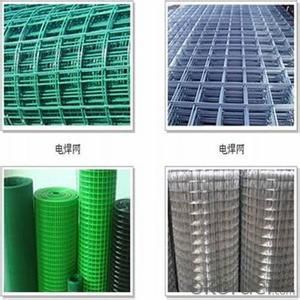

Pictures of Welded Wire Mesh

Specification of Welded Wire Mesh

Standard Welded Wire Mesh (in 30m length, Width of 0.5m-1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22-24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19-22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16-23 |

5/8" x 5/8" | 16mm x 16mm | 18-21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16-21 |

1" x 1/2" | 25.4mm x 12.7mm | 16-21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14-19 |

1" x 2" | 25.4mm x 50.8mm | 14-16 |

2" x 2" | 50.8mm x 50.8mm | 12-16 |

1/4" x 1/4" | 6.4mm x 6.4mm | 12-16 |

Welded Fencing Mesh (in 30m Length, Width of 0.5m -1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

2" x 3" | 50mm x 75mm | 1.65-2.5mm |

3" x 3" | 75mm x 756mm | 1.65-2.75mm |

2" x 4" | 50mm x 100mm | 2.1-2.9mm |

4" x 4" | 100mm x 100mm | 2.0mm,2.5mm |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is steel wire mesh resistant to vibrations or shocks?

- Yes, steel wire mesh is resistant to vibrations and shocks. Steel wire mesh is known for its high tensile strength and durability, which allows it to withstand various external forces, including vibrations and shocks. The interlocking nature of the wires in the mesh provides additional stability and resistance to movement, making it an ideal material for applications where vibrations or shocks are expected. Additionally, steel wire mesh can be further reinforced with coatings or treatments to enhance its resistance to corrosion and environmental factors, ensuring its longevity and performance in challenging conditions.

- Q: How does steel wire mesh perform in earthquake-prone areas?

- Due to its strength and durability, steel wire mesh is an excellent option for areas prone to earthquakes. It provides enhanced structural stability and reinforcement, allowing it to withstand seismic forces. Acting as a layer of reinforcement, the mesh distributes the energy generated during an earthquake, preventing the collapse or significant damage of buildings. One major advantage of steel wire mesh is its capacity to absorb and dissipate seismic energy. When an earthquake occurs, the mesh deforms under stress, absorbing the energy and reducing its impact on surrounding structures. This minimizes the risk of structural failure and ensures the safety of buildings and infrastructure. Moreover, steel wire mesh is highly flexible and can adapt to the dynamic movements caused by seismic activity. Its flexibility allows it to bend and stretch without breaking, maintaining its integrity even in extreme conditions. This property is crucial in earthquake-prone areas where ground motion and shaking can be unpredictable and intense. Additionally, steel wire mesh offers excellent corrosion resistance, which is vital in earthquake-prone regions. Corrosion can weaken the structural integrity of reinforcement materials, compromising their performance during earthquakes. However, steel wire mesh's resistance to corrosion ensures its long-term effectiveness and reliability in these regions. Furthermore, steel wire mesh is easy to install and cost-effective compared to other materials used for reinforcement. Its lightweight nature simplifies the construction process, reducing labor and time requirements. This makes it an ideal choice for retrofitting existing structures to improve their resistance to earthquakes. In conclusion, steel wire mesh is highly suitable for earthquake-prone areas. Its strength, flexibility, and ability to absorb seismic energy make it an excellent choice for reinforcement. Its corrosion resistance and cost-effectiveness further enhance its suitability for seismic retrofitting and construction projects in these regions.

- Q: What are the different coating options for steel wire mesh?

- Steel wire mesh can be coated in several ways, each offering unique advantages and qualities. Let's explore some of the most commonly used coating options: 1. Hot-dip galvanizing is a process that involves applying a layer of zinc to the steel wire mesh. This coating is highly effective in preventing corrosion, making it ideal for outdoor use and environments with high humidity or exposure to chemicals. 2. Another option is PVC coating, which is applied by either dipping or spraying the mesh with a PVC material. This coating provides protection against corrosion, abrasion, and harmful UV rays. Additionally, it adds aesthetic appeal as it comes in various colors. 3. For steel wire mesh that requires exceptional chemical resistance and durability, epoxy coatings are commonly used. This coating is applied through electrostatic spraying or dipping, forming a protective layer that prevents corrosion and provides resistance to chemicals, solvents, and abrasion. 4. Polyester coatings are often chosen for architectural applications, such as building facades or decorative panels. This coating offers excellent weather resistance, UV protection, and color retention. It is available in a wide range of colors and finishes. 5. Polyethylene coatings are highly resistant to chemicals and provide protection against corrosion and abrasion. They are typically used in applications involving harsh chemicals or abrasive substances. 6. Finally, stainless steel wire mesh, while not technically a coating, is often selected for its inherent corrosion resistance and durability. Stainless steel mesh contains chromium, which forms a passive oxide layer on the surface, protecting it from rust and corrosion. These are just a few examples of the coating options available for steel wire mesh. The choice of coating depends on factors such as the intended application, environmental conditions, and specific requirements like corrosion resistance, chemical resistance, or aesthetics.

- Q: How is steel wire mesh used in the automotive industry?

- Various applications in the automotive industry commonly use steel wire mesh. One primary usage is for vehicle safety. Car seats utilize it as a reinforcement material, ensuring strength and durability to protect passengers during collisions. By preventing seat collapse upon impact, the risk of severe injuries is reduced. Another important application is within airbag systems. The mesh functions as a component in the airbag module, guaranteeing proper deployment and directing inflation. It maintains the desired shape and size of the airbag, effectively safeguarding occupants during accidents. Steel wire mesh is also integral in manufacturing filters for automotive engines. These filters trap dust, dirt, and particles, ensuring clean airflow to the engine. Acting as a barrier, the mesh prevents larger debris from entering the engine, potentially causing damage. This enhances overall efficiency and vehicle performance. Furthermore, grilles and vents in the automotive industry incorporate steel wire mesh. These components protect crucial parts like radiators and engine compartments. By acting as a barrier, the mesh prevents debris from entering these areas, preventing damage or overheating. In conclusion, steel wire mesh plays a critical role in the automotive industry. Its applications in car seats, airbag systems, engine filters, and grilles contribute to the overall safety, performance, and longevity of vehicles.

- Q: Is steel wire mesh suitable for agricultural fencing?

- Yes, steel wire mesh is suitable for agricultural fencing. It provides durability, strength, and is capable of withstanding harsh weather conditions. Additionally, it offers effective containment for livestock and protection from predators.

- Q: Can steel wire mesh be used for catwalks?

- Yes, steel wire mesh can be used for catwalks. It is a strong and durable material that can provide a stable surface for walking, making it suitable for catwalks in various industrial and construction settings.

- Q: What are the benefits of using steel wire mesh in the manufacturing industry?

- Steel wire mesh has numerous benefits in the manufacturing industry. Firstly, it provides enhanced strength and durability, making it suitable for demanding applications. It also offers excellent resistance to corrosion and high temperatures, ensuring longevity and reliability. Additionally, steel wire mesh is highly versatile, allowing for easy customization to meet specific requirements. It provides effective filtration and separation, improving product quality. Moreover, its open design allows for better airflow and visibility, promoting safety and efficiency in manufacturing processes. Overall, steel wire mesh is a cost-effective solution that enhances productivity and offers a wide range of benefits in the manufacturing industry.

- Q: What are the different wire diameters available for steel wire mesh?

- The different wire diameters available for steel wire mesh typically range from as thin as 0.2mm to as thick as 6mm, depending on the specific application and strength requirements.

- Q: Can steel wire mesh be used for mesh trays?

- Yes, steel wire mesh can be used for mesh trays. Steel wire mesh is a durable and strong material that can withstand heavy loads and is resistant to corrosion. It is commonly used in various industrial applications, including mesh trays. Mesh trays are used for cable management and organizing electrical wires in commercial and industrial settings. The open design of steel wire mesh allows for proper ventilation and prevents the accumulation of dust and debris, making it a suitable choice for mesh trays. Additionally, steel wire mesh is easily customizable and can be tailored to specific dimensions and configurations required for different applications. Overall, steel wire mesh is a reliable and versatile material that can effectively serve as mesh trays in various industries.

- Q: Can steel wire mesh be used for water filtration?

- Water filtration can indeed utilize steel wire mesh. Steel wire mesh possesses great versatility and is highly effective in removing impurities from water, including debris, sediments, and larger particles. The desired filtration level can be achieved by selecting the appropriate mesh size, which allows for customization according to specific water quality needs. In addition, steel wire mesh is exceptionally durable, resistant to corrosion, and capable of withstanding high-pressure water flow. This makes it well-suited for a variety of filtration applications in industrial, commercial, and residential settings. Furthermore, steel wire mesh can be easily cleaned and maintained, ensuring both a long lifespan and efficient filtration performance.

Send your message to us

Welded Wire Mesh for Building -1/2 X 1/2

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords