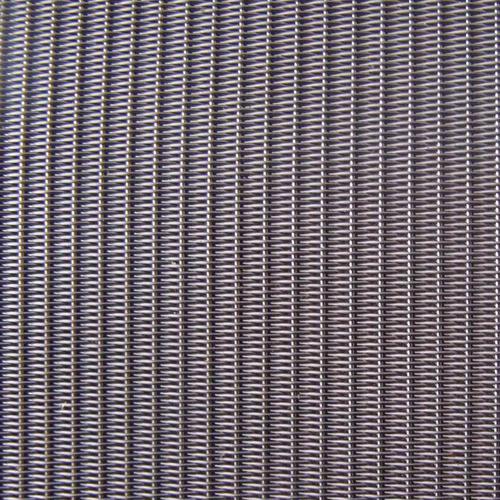

Plain Dutch Weave and Twill Dutch Weave Wire Cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PlainDutch Weave & Twill Dutch Weave Wire Cloth

PlainDutch Weave & Twill Dutch Weave Wire Cloth Specifications

Thetable below shows the standard specifications for FLS’s Plain Dutch and TwillDutch weave wire cloth.

WEAVE TYPE | MESH COUNT | WARP WIRE | SHUTE WIRE | ABSOLUTE | NOMINAL | WEIGHT |

IN INCHES | IN INCHES | MICRON RATING | MICRON RATING | PER 100 SQ.' | ||

PDW | 8X20 | 0.014 | 0.0126 | 330-350 | 280 | 49 |

PDW | 12X64 | 0.024 | 0.0165 | 270-290 | 200 | 84 |

PDW | 14X88 | 0.02 | 0.013 | 220-240 | 150 | 75 |

PDW | 16X80 | 0.0169 | 0.0134 | 225-235 | 140 | 79 |

PDW | 24X110 | 0.015 | 0.01 | 115-125 | 80 | 55 |

PDW - TWIN WARP | 24X128 | 2 X .010 | 0.004 | 110-120 | 75 | 34 |

PDW | 30X150 | 0.009 | 0.007 | 110-112 | 63 | 33 |

PDW - TWIN WARP | 30X150 | 2 X .009 | .007" | 95-113 | 60 | 33 |

PDW | 40X200 | 0.007 | 0.0055 | 70-75 | 55 | 27 |

PDW | 50X250 | 0.0055 | 0.0045 | 58-63 | 40 | 22 |

PDW | 80X400 | 0.005 | 0.003 | 40-45 | 35 | 17 |

TDW | 30X250 | 0.01 | 0.008 | 110-120 | 53 | 66 |

TDW | 80X700 | 0.004 | 0.003 | 35-40 | 25 | 25 |

TDW | 120X400 | 0.004 | 0.0025 | 50-55 | 40 | 15 |

TDW | 165X800 | 0.0028 | 0.002 | 25-28 | 15 | 14 |

TDW | 200X600 | 0.0024 | 0.0018 | 30 | 20 | 10 |

TDW | 165X1400 | 0.0028 | 0.0016 | 16-20 | 10 | 14 |

TDW | 200X1400 | 0.0028 | 0.0016 | 12-14 | 5 | 15 |

TDW | 325X2300 | 0.0014 | 0.001 | 8-9 | 2 | 10 |

TDW | 400X2800 | 0.001 | 0.0008 | 6-7 | 1 | 8 |

- Q: How is steel wire mesh maintained?

- Steel wire mesh can be maintained by following a few simple steps. First, it is important to regularly clean the mesh to remove any dirt, debris, or rust that may accumulate over time. This can be done by using a soft brush or cloth to gently scrub the surface of the mesh, while being careful not to damage or snag the wires. Additionally, if there are any stubborn stains or rust spots, a mild detergent or rust remover can be used. After cleaning, the mesh should be thoroughly rinsed with clean water to remove any remaining residue. To prevent rust and corrosion, it is recommended to apply a protective coating or paint to the steel wire mesh. This coating acts as a barrier, shielding the mesh from moisture and other corrosive elements. The type of coating used will depend on the specific environment and purpose of the mesh, so it is important to consult with a professional or manufacturer for the most suitable option. Regular inspections should also be conducted to identify any signs of damage or wear. If any wires are broken, bent, or loose, they should be repaired or replaced as soon as possible to maintain the integrity of the mesh. Additionally, any sharp edges or protrusions should be filed or smoothed out to prevent injury. Lastly, it is important to be mindful of the load and stress that the steel wire mesh is subjected to. Overloading or excessive force can lead to deformation or breakage. It is crucial to follow the manufacturer's guidelines and recommended weight limits to ensure the longevity and functionality of the mesh. Overall, proper maintenance of steel wire mesh involves regular cleaning, applying protective coatings, conducting inspections, and being mindful of load limits. By following these steps, the mesh can be kept in optimal condition, ensuring its durability and effectiveness for various applications.

- Q: How does steel wire mesh perform in terms of impact resistance?

- The exceptional impact resistance of steel wire mesh is widely recognized. It is specifically engineered to endure significant force and impact without any deformation or breakage. This outstanding performance can be attributed to the inherent strength and durability of steel, which is renowned for its capacity to absorb and distribute impact energy. Steel wire mesh is commonly employed in applications that demand high levels of impact resistance, such as security fencing, road barriers, and industrial equipment. It is capable of withstanding heavy loads, collisions, and other external forces, making it the optimal choice for areas prioritizing protection and safety. Furthermore, steel wire mesh also offers a certain degree of flexibility, enabling it to effectively absorb and dissipate impact energy. Consequently, steel wire mesh is highly dependable and exhibits exceptional performance when it comes to impact resistance.

- Q: Is steel wire mesh suitable for use in sports facilities?

- Yes, steel wire mesh is suitable for use in sports facilities. It is a durable and strong material that can withstand high impact and provide security. It is commonly used for fencing, cages, and barriers in sports facilities to ensure the safety of players and spectators. The mesh design allows for visibility and proper airflow, making it suitable for various sports such as soccer, baseball, and tennis.

- Q: How does steel wire mesh differ from other types of wire mesh?

- Steel wire mesh differs from other types of wire mesh primarily due to its high strength and durability. Unlike other materials used for wire mesh, such as aluminum or copper, steel wire mesh is known for its exceptional tensile strength, making it suitable for heavy-duty applications. Additionally, steel wire mesh is resistant to corrosion and can withstand harsh environmental conditions. These qualities make steel wire mesh highly popular in industries requiring strong and long-lasting wire mesh solutions, such as construction, agriculture, and mining.

- Q: Does steel wire mesh rust?

- Indeed, steel wire mesh has the capacity to rust. Rust emerges as a consequence of the oxidation procedure which takes place when iron or steel comes into contact with moisture and oxygen. In the event that the steel wire mesh lacks appropriate coating or protection, it becomes vulnerable to rusting as time passes. Nevertheless, there exist diverse techniques to impede or decrease rusting, for instance, by galvanizing the steel wire mesh or administering a safeguarding coating. By implementing these measures, the lifespan of the mesh can be greatly prolonged, guaranteeing its durability.

- Q: How is steel wire mesh used in geotechnical engineering?

- Steel wire mesh is commonly used in geotechnical engineering for various applications. One of the primary uses of steel wire mesh is in soil stabilization. When soil is weak or loose, it can lead to slope instability or erosion. Steel wire mesh is used to reinforce the soil and increase its strength and stability. It is typically installed horizontally or vertically in the ground to create a strong barrier that prevents soil movement and retains its shape. Steel wire mesh is also utilized in retaining walls and embankments. These structures are built to hold back soil or rock masses and prevent landslides or collapses. The mesh is installed within the soil or behind the retaining wall to reinforce it and provide additional strength. This helps to distribute the forces exerted by the soil or rock mass evenly, reducing the risk of failure. In addition, steel wire mesh is employed in erosion control systems. It is installed on slopes or riverbanks to protect the soil from erosion caused by water or wind. The mesh acts as a barrier, preventing the soil particles from being washed away or blown off. By stabilizing the soil and reducing erosion, steel wire mesh helps to maintain the integrity of the landscape and prevent environmental damage. Furthermore, steel wire mesh is used in geotechnical engineering for rockfall protection. In areas where there is a risk of rockfall, such as mountainous regions or along highways, steel wire mesh is installed to catch and contain falling rocks. The mesh is anchored to the slope or cliff face, creating a protective barrier that prevents rocks from reaching the ground and posing a hazard to people or structures below. Overall, steel wire mesh plays a crucial role in geotechnical engineering by providing reinforcement, stability, and protection to various structures and landscapes. Its versatility and durability make it a preferred choice for applications that require strength and resistance to environmental factors.

- Q: Can steel wire mesh be used for catwalks?

- Catwalks can indeed utilize steel wire mesh. This versatile material presents numerous benefits when used in catwalk applications. Boasting a robust and enduring walking surface, steel wire mesh is fully capable of withstanding heavy loads. Its open design allows for effortless drainage, significantly reducing the risk of slipping caused by water accumulation. Moreover, this material's resistance to rust and corrosion renders it suitable for both indoor and outdoor catwalks. Customization to specific dimensions is easily achievable, and installation is swift, saving both time and effort. On the whole, steel wire mesh proves to be a dependable and cost-effective choice for catwalks, ensuring both functionality and safety.

- Q: What are the different colors available for steel wire mesh?

- There are several different colors available for steel wire mesh, depending on the specific requirements and preferences of the customer. The most commonly used color for steel wire mesh is silver, which is the natural color of stainless steel. This color is often chosen for its sleek and industrial look. However, steel wire mesh can also be coated or painted in various colors to provide enhanced aesthetics or to match the surrounding environment. Some popular coating options include black, green, and white. These colored coatings not only add a touch of vibrancy but can also provide additional protection against corrosion and UV rays. Ultimately, the color options for steel wire mesh are diverse, allowing customers to choose the most suitable option for their specific application or design.

- Q: Is steel wire mesh suitable for marine applications?

- Steel wire mesh proves to be an excellent option for marine applications. With its exceptional strength and durability, it is well-suited for marine environments that expose it to harsh elements like saltwater, waves, and corrosive substances. Moreover, its resistance to rust and corrosion ensures a lengthy lifespan even in marine settings. Furthermore, steel wire mesh offers a high level of security and protection, making it appropriate for marine applications such as fencing, enclosures, and barriers. Its versatility allows for various uses in marine structures, including filtration, reinforcement, and containment. In summary, steel wire mesh is a dependable and efficient choice for marine applications due to its strength, durability, corrosion resistance, and ability to provide security and protection.

- Q: How durable is steel wire mesh?

- Known for its high durability, steel wire mesh is specifically designed to withstand heavy loads, resist corrosion, and maintain its structural integrity over time. The durability of steel wire mesh is dependent on several factors including the thickness of the wire, the size of the mesh openings, and the type of steel utilized. In general, steel wire mesh exhibits remarkable resistance to impact, abrasion, and extreme weather conditions, rendering it suitable for a wide array of applications. Its versatility allows for utilization in construction, agriculture, mining, fencing, and diverse industrial settings where strength and longevity are of utmost importance. By conducting regular inspections and implementing proper maintenance, steel wire mesh can serve as a reliable and robust solution for a variety of needs, lasting for numerous years.

Send your message to us

Plain Dutch Weave and Twill Dutch Weave Wire Cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords