High Rib Lath

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

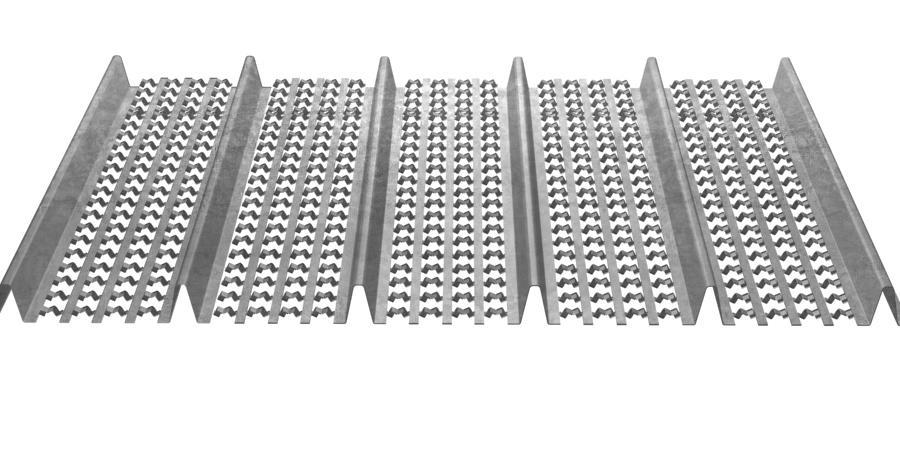

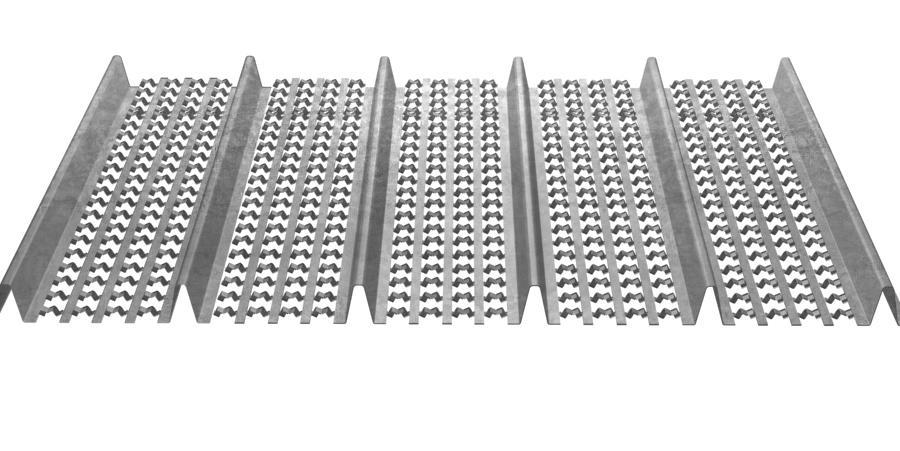

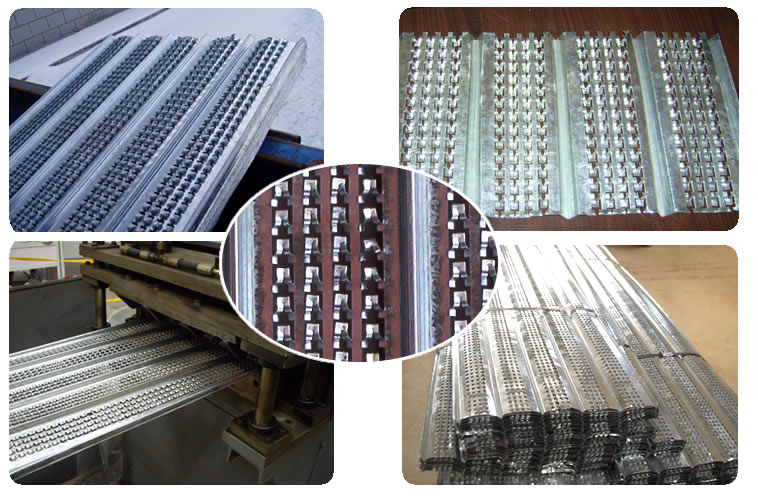

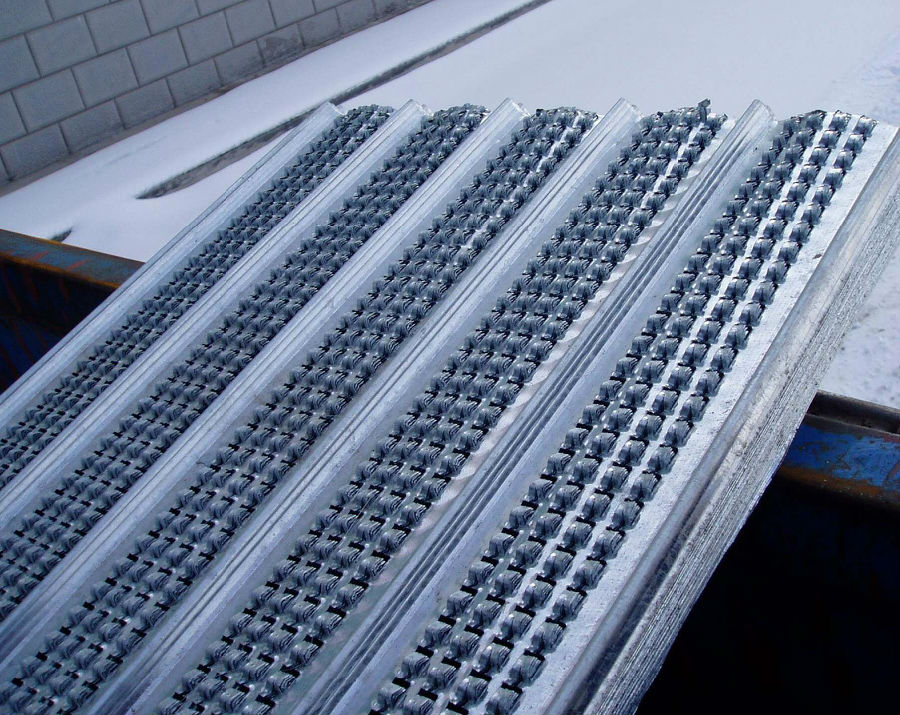

High Ribbed Formwork is made from hot dipped galvanized steel sheets. The mesh and ribs are formed on machines which first cut and press the mesh and then roll form the ribs. At the same time the material is stretched to form an expanded mesh.

Matal Rib Lath/High Rib Lath

Concreting mould mesh

Material: hot-dipped galvanized steel sheet

Thickness: 0.1-0.5mm

Size: 450x2000mm

ISO9001 certific

Feature: Because of its meshes and U patterns, it has better anti-stress capability and forming flexibility than normal metal lath. This product has excellent engineering quality, construction security

Application:

1).Construction formwork mesh has very good engineering quality and construction security;

2).Construction formwork mesh as the concrete permanent assembly

free sheet is much convenient for engineering design and processing;

3).Construction formwork mesh is widely used in tunnels,bridges and valve system and so on

to make the process of construction much more fast and stable.

Specification:

Thickness (mm) | Weight (kg) | Width (mm) | Length (mm) | Area (m2) |

0.2 | 1.70 | 445 | 2200 | 0.99 |

0.25 | 2.10 | 445 | 2200 | 0.99 |

0.30 | 2.60 | 445 | 2200 | 0.99 |

0.35 | 3.00 | 445 | 2200 | 0.99 |

0.40 | 3.40 | 450 | 2200 | 0.99 |

0.45 | 3.80 | 450 | 2200 | 0.99 |

0.50 | 4.20 | 450 | 2200 | 0.99 |

0.55 | 4.60 | 450 | 2200 | 0.99 |

0.60 | 5.00 | 450 | 2200 | 0.99 |

- Q: Can steel wire mesh be used for playground equipment?

- Certainly, playground equipment can utilize steel wire mesh. Steel wire mesh proves to be a highly adaptable and sturdy substance, offering a multitude of advantages for playground equipment. It is frequently employed in the construction of partitions, enclosures, climbing frames, and protective nets within playgrounds. The robustness and tenacity of steel wire mesh render it apt for supporting the weight of children and ensuring their safety during playtime. Furthermore, steel wire mesh exhibits a resistance to corrosion and can endure diverse weather conditions, thus establishing itself as a durable choice for playground equipment. The mesh's design also permits excellent visibility and ventilation, fostering a secure and enjoyable environment for play.

- Q: How is steel wire mesh used in the automotive aftermarket industry?

- Steel wire mesh is commonly used in the automotive aftermarket industry for a variety of purposes. One of the main applications of steel wire mesh is in car grilles. These grilles are responsible for protecting the car's front end, particularly the radiator, from debris and other potential damage. Steel wire mesh is used in the construction of these grilles due to its high strength and durability. Steel wire mesh is also used in the production of car seat covers. The mesh is woven tightly to create a breathable and comfortable surface for the driver and passengers. This allows air to circulate and reduces the discomfort caused by sitting in a car for long periods of time. Additionally, steel wire mesh is utilized in the production of filters for various automotive components. These filters play a crucial role in maintaining the performance and longevity of different systems in a vehicle, such as the air intake system, oil filtration, and fuel filtration. The steel wire mesh used in these filters helps to trap and prevent contaminants from entering and damaging the internal components of the automotive systems. In the automotive aftermarket industry, steel wire mesh is also used for customizing vehicles. It can be used to create unique and visually appealing designs, such as mesh grilles, body panels, or even speaker covers. Its versatility and ability to be easily shaped and molded make it a popular choice for car enthusiasts looking to enhance the aesthetics of their vehicles. Overall, steel wire mesh is an essential component in the automotive aftermarket industry. It is used for various applications, including grille production, seat covers, filters, and customization. Its strength, durability, and versatility make it an ideal material for enhancing both the functionality and appearance of vehicles.

- Q: Can steel wire mesh be used for fireplace screens?

- Yes, steel wire mesh can be used for fireplace screens. It is a durable material that can withstand high temperatures and effectively prevent sparks and embers from escaping the fireplace, ensuring safety and protection.

- Q: When will the masonry be hung?

- 2, whether the wall is full of steel wire mesh According to the design requirements and construction organization design, the external walls to full of wire mesh is generally very little.

- Q: How does the surface pattern affect the grip of steel wire mesh?

- The surface pattern of steel wire mesh plays a crucial role in determining its grip. The grip of wire mesh refers to its ability to securely hold objects or provide traction. The surface pattern of wire mesh refers to the specific arrangement and design of the raised or textured features on its surface. These patterns can range from simple to complex and can significantly impact the grip characteristics of the mesh. A rough or textured surface pattern on the wire mesh enhances its grip by increasing the contact area between the mesh and the object or surface it is in contact with. The irregularities or protrusions on the surface pattern create more friction, ensuring a stronger grip. This is particularly useful in applications where grip is essential, such as in industrial settings where wire mesh is used as flooring or walkways to prevent slipping. On the other hand, a smooth surface pattern may reduce the grip of the wire mesh. A smooth surface offers less friction and contact area, making it less effective in providing a secure grip. However, there may be instances where a smooth surface pattern is desired, such as in certain architectural or decorative applications. It is important to consider the intended use and requirements when selecting wire mesh with an appropriate surface pattern. Factors such as load-bearing capacity, environmental conditions, and the type of objects or surfaces that will come into contact with the mesh should be taken into account. By choosing the right surface pattern, the grip of steel wire mesh can be optimized for various applications, ensuring safety, stability, and functionality.

- Q: Is steel wire mesh suitable for use in wastewater treatment plants?

- Yes, steel wire mesh is suitable for use in wastewater treatment plants. It is durable, corrosion-resistant, and can effectively filter out solids from wastewater, making it an ideal material for various applications in wastewater treatment processes.

- Q: Can steel wire mesh be bent?

- Indeed, steel wire mesh possesses the ability to undergo bending. This malleable substance can effortlessly be molded into a multitude of configurations and structures. Employing a diverse array of tools, such as pliers or wire cutters, one can successfully achieve the desired shape or curvature. The inherent flexibility of steel wire mesh renders it suitable for a vast spectrum of applications, spanning from construction and landscaping to industrial endeavors. Nonetheless, the extent to which steel wire mesh may be bent is contingent upon its thickness and strength. In instances where the wire mesh is thicker and stronger, additional force or specialized equipment may be necessary to facilitate the bending process.

- Q: Galvanized welded wire mesh and hot galvanized steel wire mesh What is the difference

- Hot galvanized welded wire mesh, hot galvanized steel wire mesh is mainly used for general building facades, pouring concrete, high-rise residential, etc., in the insulation system plays an important structural role in the construction of steel wire mesh formed by cracking mortar protective layer

- Q: Is steel wire mesh suitable for playground equipment?

- Steel wire mesh proves to be an ideal option for playground equipment due to its strength and durability. This material can withstand extensive usage, guaranteeing a secure play environment for kids. It is frequently employed in various playground structures, fences, and safety barriers. Thanks to its resistance to wear and tear, corrosion, and weather conditions, steel wire mesh stands out as an excellent choice for outdoor playgrounds. Furthermore, the mesh's openings are typically compact enough to prevent children from trapping their fingers or other body parts, ensuring their safety during playtime. Ultimately, steel wire mesh emerges as a dependable and appropriate material for playground equipment.

- Q: Can steel wire mesh be used for mesh baskets?

- Mesh baskets can indeed utilize steel wire mesh. This material is frequently employed for various purposes, mesh baskets being one of them. With its strength, durability, and corrosion resistance, steel wire mesh proves to be the perfect choice for constructing baskets capable of enduring heavy loads and harsh environments. Moreover, the mesh's open structure facilitates adequate airflow and visibility, rendering it suitable for storing and arranging items. Furthermore, steel wire mesh can be effortlessly tailored to different dimensions and forms, granting flexibility in designing mesh baskets to suit specific requirements.

Send your message to us

High Rib Lath

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches