Welded Wire Mesh for Glasswool -5/8 X 5/8

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

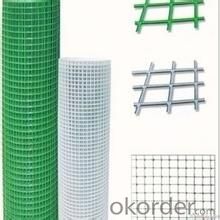

Introduction of Welded Wire Mesh

Welded Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire, PVC coated iron wire in blue, green, yellow and other colors.

Application of Welded Wire Mesh

Galvanized welded wire mesh, PVC coated welded wire mesh for garden, feeding agriculture, fishing, poultry, mine field, lawn cultivation, and profession’s guard, decorate machine protection. Special welded wire mesh, (Heavy)welded wire mesh panel service as fencing mesh for transportation industry, construction a agriculture.

Surface treatment of of Welded Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Pvc coated welded wire mesh, (black wire mesh then pvc coated, electro gal. then pvc coated, hot dip gal. the pvc coated)

Advantage of Welded Wire Mesh

Our welded wire mesh has strong corrosion-resisting and oxidation-resisting with good quality and rock bottom price.

Packing of Welded Wire Mesh

1. Waterproof paper then PVC shrinking Film

2. PVC shrinking film only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

Pictures of Welded Wire Mesh

Specification of Welded Wire Mesh

Standard Welded Wire Mesh (in 30m length, Width of 0.5m-1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22-24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19-22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16-23 |

5/8" x 5/8" | 16mm x 16mm | 18-21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16-21 |

1" x 1/2" | 25.4mm x 12.7mm | 16-21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14-19 |

1" x 2" | 25.4mm x 50.8mm | 14-16 |

2" x 2" | 50.8mm x 50.8mm | 12-16 |

1/4" x 1/4" | 6.4mm x 6.4mm | 12-16 |

Welded Fencing Mesh (in 30m Length, Width of 0.5m -1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

2" x 3" | 50mm x 75mm | 1.65-2.5mm |

3" x 3" | 75mm x 756mm | 1.65-2.75mm |

2" x 4" | 50mm x 100mm | 2.1-2.9mm |

4" x 4" | 100mm x 100mm | 2.0mm,2.5mm |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What are the benefits of using steel wire mesh in the automotive recycling industry?

- There are several benefits of using steel wire mesh in the automotive recycling industry. Firstly, steel wire mesh is extremely durable and strong, making it suitable for handling heavy objects and materials. This is particularly important in the automotive recycling industry, where large and heavy parts need to be sorted, separated, and transported. Steel wire mesh can withstand the weight and pressure of these parts without getting damaged, ensuring a safe and reliable operation. Secondly, steel wire mesh is highly resistant to corrosion. As the automotive recycling industry deals with various materials, including those that may contain chemicals or fluids, the risk of corrosion is high. However, steel wire mesh's resistance to corrosion ensures a longer lifespan, reducing the need for frequent replacements and saving costs in the long run. Moreover, steel wire mesh is versatile and can be customized to fit specific requirements. Automotive recycling facilities often have unique needs in terms of size, shape, and design of their sorting and separation equipment. Steel wire mesh can be easily fabricated and tailored to meet these specific needs, allowing for efficient and effective operations. Additionally, steel wire mesh is easy to clean and maintain. In the automotive recycling industry, where debris, dust, and fluids are common, regular cleaning is essential to maintain a hygienic working environment. Steel wire mesh's open design allows for easy access and cleaning, ensuring a clean and safe workplace. Lastly, steel wire mesh is environmentally friendly. As the automotive recycling industry focuses on reducing waste and promoting sustainability, using steel wire mesh aligns with these goals. Steel wire mesh is recyclable, meaning it can be reused or repurposed after its lifespan in the industry, reducing the overall environmental impact. In conclusion, the benefits of using steel wire mesh in the automotive recycling industry include durability, corrosion resistance, versatility, ease of maintenance, and environmental friendliness. These advantages contribute to a more efficient and sustainable operation, making steel wire mesh an ideal choice for automotive recycling facilities.

- Q: Does steel wire mesh require any special maintenance?

- Yes, steel wire mesh does require some special maintenance. Regular cleaning of the mesh is important to remove any dirt or debris that may accumulate on its surface. This can be done using a soft brush or cloth along with mild soap and water. Additionally, it is recommended to inspect the mesh periodically for any signs of corrosion or damage. If corrosion is detected, it is necessary to treat the affected areas with a rust inhibitor and repaint if necessary. Lubricating the joints and moving parts of the mesh can also help to ensure smooth operation. Overall, proper maintenance can extend the lifespan of steel wire mesh and ensure its optimal performance.

- Q: How is steel wire mesh used in reinforcement of swimming pools?

- Steel wire mesh is commonly used in the reinforcement of swimming pools to provide additional strength and stability to the pool structure. The mesh is typically installed within the concrete walls and floor of the pool, acting as a supportive framework that helps to prevent cracking and shifting. This reinforcement ensures that the pool can withstand the pressure exerted by water and external forces, increasing its durability and lifespan.

- Q: Can steel wire mesh be used for tree protection?

- Tree protection can indeed be achieved with the use of steel wire mesh. This material, which is both durable and versatile, is highly effective in shielding trees against a range of external factors. These factors include animals, vandalism, and harsh weather conditions. By forming a physical barrier around the tree, steel wire mesh prevents animals from reaching the trunk and causing harm to the bark. Furthermore, this mesh can be utilized to create a protective cage or enclosure around young trees. This shelter shields them from strong winds, heavy rainfall, and snowfall. Importantly, the mesh allows for proper airflow and sunlight penetration, enabling the tree's health and growth. All in all, steel wire mesh is an outstanding choice for tree protection due to its strength, durability, and capacity to endure diverse environmental conditions.

- Q: What are the different weave patterns available for steel wire mesh?

- There are several different weave patterns available for steel wire mesh, each offering unique characteristics and applications. Some of the most common weave patterns include: 1. Plain weave: This is the most basic and commonly used weave pattern, where each weft wire passes alternately over and under each warp wire. It creates a strong and stable mesh with equal strength in both directions. 2. Twill weave: In this pattern, each weft wire passes over and under two warp wires, resulting in a diagonal pattern. Twill weave offers higher tensile strength and is commonly used for heavy-duty applications. 3. Dutch weave: Dutch weave patterns have a higher density of warp wires compared to the weft wires. The warp wires are usually larger in diameter, resulting in a tight mesh with excellent filtration capabilities. Dutch weave is commonly used for fine filtration applications. 4. Reverse Dutch weave: This weave pattern is the opposite of the Dutch weave, where the weft wires are larger in diameter compared to the warp wires. It creates a mesh with larger openings and higher flow rates, making it suitable for applications requiring high pressure or high flow rates. 5. Five-heddle weave: This weave pattern is characterized by a unique arrangement of warp and weft wires, resulting in a stable mesh with larger openings. It is commonly used for architectural applications like facades and decorative panels. 6. Welded mesh: Unlike woven mesh, welded mesh is created by welding intersecting wires together. It offers superior strength and stability, making it suitable for applications that require high impact resistance and security, such as fencing and reinforcement. These are just a few of the many weave patterns available for steel wire mesh. The choice of weave pattern depends on the specific application requirements, such as strength, filtration, stability, or aesthetics. Manufacturers can also customize the weave patterns to meet unique project needs.

- Q: What are the different types of weaves available for steel wire mesh?

- There are several types of weaves available for steel wire mesh, including plain weave, twill weave, Dutch weave, and reverse Dutch weave.

- Q: Is steel wire mesh suitable for use in soundproofing applications?

- Soundproofing applications can benefit greatly from the use of steel wire mesh. This versatile material, also known as acoustic mesh or soundproof mesh, has unique properties that make it effective in blocking and absorbing sound waves. It is commonly used in architectural projects, industrial applications, and even residential settings. The density and sturdiness of steel wire mesh allow it to effectively block the transmission of sound waves. Its mesh structure disperses and absorbs sound waves, resulting in reduced noise levels. This material can be customized to fit different soundproofing requirements, with options available in terms of thickness, patterns, and sizes. It can be installed as screens, panels, or wraps depending on the specific application and desired level of soundproofing. Steel wire mesh is also highly durable and able to withstand harsh environmental conditions. It is corrosion-resistant, fire-resistant, and can handle high temperatures, making it suitable for both indoor and outdoor soundproofing applications. To sum up, steel wire mesh is an excellent choice for soundproofing due to its ability to effectively block and absorb sound waves. Its versatility, durability, and customizable options make it suitable for a wide range of soundproofing projects.

- Q: How is steel wire mesh used in reinforcement of embankments?

- Steel wire mesh is commonly used in the reinforcement of embankments to provide stability and prevent erosion. The mesh is typically placed within the embankment structure to distribute the load and improve its overall strength. When constructing embankments, such as those found in roadways, railways, or retaining walls, steel wire mesh is often incorporated as a reinforcement measure. The mesh is made up of interlocking strands of steel wire, forming a grid-like pattern. This grid acts as a reinforcement layer that enhances the embankment's resistance to external forces, such as the weight of the soil, water pressure, or ground movements. The main function of steel wire mesh in embankment reinforcement is to distribute the load more evenly across the structure. By providing a continuous network of interconnected wires, the mesh helps to transfer the load from the surface to the underlying layers, reducing the risk of localized failures or deformations. This is especially important in areas with weak or unstable soils, where the mesh can help to stabilize the embankment and prevent settlement or collapse. Additionally, steel wire mesh can also serve as a barrier against erosion. It helps to retain the soil particles within the embankment, preventing them from being washed away by water or wind. This is particularly crucial in embankments located near rivers, streams, or coastal areas, where the risk of erosion is higher. The use of steel wire mesh in embankment reinforcement offers several advantages. It is a cost-effective solution compared to alternative methods, such as using concrete or geosynthetic materials. Steel wire mesh is also relatively easy to install and can be customized to fit the specific requirements of the embankment project. Furthermore, its durability and resistance to corrosion ensure a long lifespan, providing long-term stability and protection to the embankment structure. In conclusion, steel wire mesh plays a crucial role in the reinforcement of embankments. It enhances the embankment's strength, stability, and resistance to external forces, while also preventing erosion. Its cost-effectiveness, ease of installation, and durability make it a preferred choice for many embankment construction projects.

- Q: Can steel wire mesh be used for creating insect screens or window grilles?

- Yes, steel wire mesh can be used for creating insect screens or window grilles. It provides durability and strength, making it an effective barrier against insects while allowing air flow and visibility.

- Q: How is steel wire mesh measured?

- Steel wire mesh is typically measured using two main parameters: the mesh size and the wire diameter. The mesh size refers to the number of openings per linear inch in the mesh. It is often denoted as a count, such as 4 mesh, 10 mesh, or 50 mesh. A 4 mesh steel wire mesh, for example, means that there are four openings per linear inch in the mesh. The higher the mesh count, the smaller the openings in the mesh. Mesh sizes can vary widely depending on the intended application and the desired level of filtration or protection. The wire diameter, on the other hand, refers to the thickness of the wire used to make the mesh. It is typically measured in either gauge or inches. For instance, a 12-gauge wire mesh means that the wire used has a diameter of 0.1046 inches, while a 1/4-inch wire mesh indicates that the wire diameter is 0.2500 inches. The wire diameter can impact the strength and durability of the mesh, with thicker wires generally providing greater strength but potentially reducing flexibility. When purchasing steel wire mesh, it is important to consider both the mesh size and the wire diameter to ensure that the mesh meets the specific requirements of the intended application.

Send your message to us

Welded Wire Mesh for Glasswool -5/8 X 5/8

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords