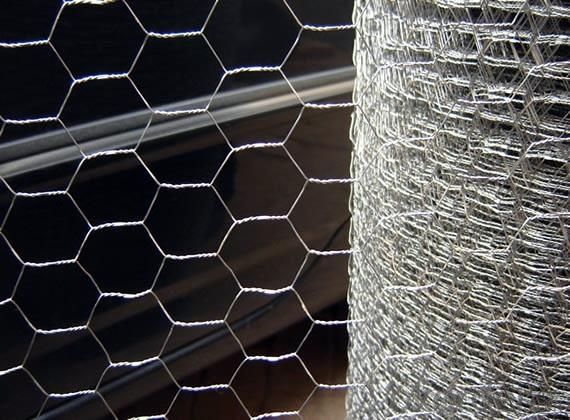

Hexagonal Galvanized Wire Netting After Weaving

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

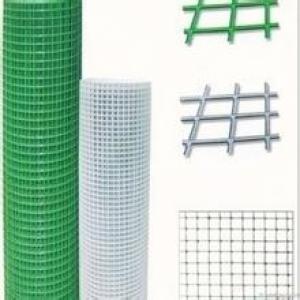

Introduction of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

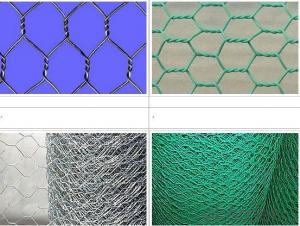

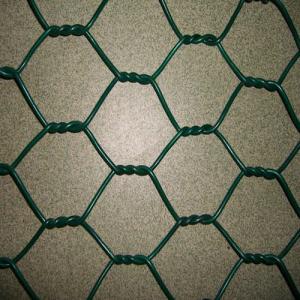

Surface treatment of Galvanized Hexagonal Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

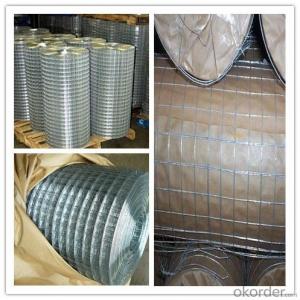

Pictures of Galvanized Hexagonal Wire Mesh

Specification of Galvanized Hexagonal Wire Mesh

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is steel wire mesh resistant to fungal or bacterial growth?

- Yes, steel wire mesh is generally resistant to fungal or bacterial growth due to its non-porous and non-absorbent properties.

- Q: What are the benefits of using steel wire mesh in the mining industry?

- One of the main benefits of using steel wire mesh in the mining industry is its high strength and durability. Steel wire mesh is able to withstand heavy loads and harsh conditions, making it ideal for use in mining operations. Additionally, steel wire mesh is resistant to corrosion, which is crucial in environments where moisture and chemicals are present. It also provides excellent visibility and ventilation, ensuring the safety and well-being of workers. Overall, steel wire mesh enhances operational efficiency, promotes safety, and reduces maintenance and replacement costs in the mining industry.

- Q: How does the temperature resistance affect the performance of steel wire mesh?

- The temperature resistance of steel wire mesh has a significant impact on its performance. Steel wire mesh is commonly used in various applications where it is exposed to different temperature conditions. Firstly, a higher temperature resistance of the steel wire mesh ensures that it can withstand extreme heat without losing its structural integrity. This is particularly important in industrial settings where the wire mesh may be exposed to high temperatures during manufacturing processes or in applications that involve heat transfer. If the wire mesh cannot withstand the temperature, it may deform, lose its shape, or even melt, rendering it useless and compromising the overall performance of the system it is being used in. Secondly, the temperature resistance of steel wire mesh also affects its mechanical properties. Steel wire mesh is often used for its strength and durability, and these properties can be affected by temperature changes. As the temperature increases, the strength of the wire mesh may decrease, leading to reduced load-bearing capacity. This can be critical in applications where the wire mesh is used for structural purposes or in situations where safety is a concern. In extreme cases, the wire mesh may fail completely, resulting in potential accidents or damage to the surrounding infrastructure. Moreover, the temperature resistance of steel wire mesh also influences its corrosion resistance. When exposed to high temperatures, the risk of oxidation and corrosion increases. If the wire mesh is not resistant to such corrosion, it can lead to rusting, weakening the structure and shortening its lifespan. Corrosion can also affect the appearance of the wire mesh, making it less visually appealing or suitable for certain applications. In conclusion, the temperature resistance of steel wire mesh plays a crucial role in determining its performance. A higher temperature resistance ensures that the wire mesh can withstand extreme heat without losing its structural integrity, maintains its mechanical properties, and prevents corrosion. It is essential to consider the temperature requirements of the application when selecting steel wire mesh to ensure optimal performance and longevity.

- Q: Can steel wire mesh be used for construction?

- Yes, steel wire mesh can be used for construction. It is commonly utilized for reinforcing concrete structures such as walls, floors, and foundations. The mesh provides additional strength and durability to the construction materials, making them more resistant to cracks and structural failures. Additionally, steel wire mesh can be used for other construction purposes like fencing, partitions, and safety barriers.

- Q: Can steel wire mesh be used for erosion control and slope stabilization?

- Yes, steel wire mesh can be used for erosion control and slope stabilization. Steel wire mesh is often used in these applications due to its strength, durability, and ability to withstand harsh environmental conditions. The mesh is typically installed on slopes or banks to provide stabilization by preventing soil erosion and retaining the soil in place. It acts as a barrier, preventing the movement of soil particles while allowing water to flow through. The steel wire mesh is typically anchored to the ground using various methods such as stakes or anchors. This helps to reinforce the slope and prevent further erosion. Additionally, the steel wire mesh can also be used in combination with vegetation to enhance its effectiveness. Overall, steel wire mesh is a reliable and effective solution for erosion control and slope stabilization applications.

- Q: Can steel wire mesh be painted?

- Yes, steel wire mesh can be painted. However, it is important to properly prepare the surface before painting to ensure good adhesion and durability of the paint. Firstly, the mesh should be thoroughly cleaned to remove any dirt, grease, or rust. A wire brush or sandpaper can be used to smooth out any rough edges or rust spots. After cleaning, it is recommended to apply a primer specifically designed for metal surfaces to promote better paint adhesion and prevent corrosion. Once the primer has dried, you can proceed to paint the steel wire mesh using a paint suitable for metal applications. It is important to follow the manufacturer's instructions for the paint and allow sufficient drying time between coats. Overall, with proper preparation and the right type of paint, steel wire mesh can be successfully painted to achieve the desired appearance and protection.

- Q: What is the role of steel wire mesh in the outer wall of the building

- Two cases require hanging wire mesh, one is the external wall insulation requirements, a construction process requirements, because now most of the high-level hollow block, hollow block and concrete expansion coefficient is not the same, prone to cracks, resulting in external walls Water leakage and affect the appearance of the general circumstances do not require full hanging, asked to hang the site: the horizontal direction of steel wire mesh - need to consider the block wall and concrete beam intersection, the block wall and concrete column (wall) When the block gable intersects the oblique beam.

- Q: Can steel wire mesh be used for gutter guards?

- Certainly! Gutter guards can indeed utilize steel wire mesh. This sturdy and resilient material effectively obstructs the entry of leaves, debris, and other solid particles into the gutter system. By placing it over the top of the gutter, a protective barrier is formed that permits water to flow through while obstructing larger objects. Due to its rust and corrosion resistance, steel wire mesh proves to be a durable choice for safeguarding gutters. Nonetheless, it is crucial to ensure that the mesh possesses a sufficiently fine grid size to prevent the passage of small debris. Additionally, regular maintenance and cleaning may still be necessary to maintain the optimal functionality of the gutter guards.

- Q: Can steel wire mesh be used for creating mesh baskets?

- Yes, steel wire mesh can be used for creating mesh baskets. Steel wire mesh is strong, durable, and has a high load-bearing capacity, making it an ideal material for constructing baskets that can hold and store various items securely. Additionally, the open design of the mesh allows for proper ventilation and visibility, making it suitable for storing items that require airflow or easy identification.

- Q: What are the different wire mesh dimensions available in steel wire mesh?

- The dimensions of steel wire mesh can vary depending on the specific needs and applications. Common dimensions include mesh sizes ranging from small openings like 1/4 inch to larger openings like 4 inches. The wire diameter used can also vary, with options ranging from thin gauges like 18 or 20 gauge to thicker gauges like 10 or 12 gauge. Additionally, the width and length of steel wire mesh sheets can vary based on the manufacturer and customer requirements.

Send your message to us

Hexagonal Galvanized Wire Netting After Weaving

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords