Welded Wire Mesh in Building Construction -1/2 X 1

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

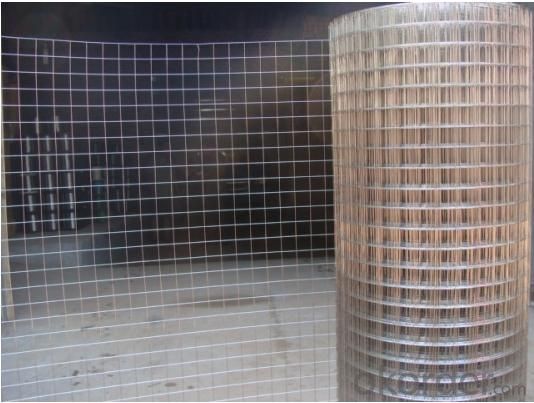

Introduction of Welded Wire Mesh

Welded Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire, PVC coated iron wire in blue, green, yellow and other colors.

Application of Welded Wire Mesh

Galvanized welded wire mesh, PVC coated welded wire mesh for garden, feeding agriculture, fishing, poultry, mine field, lawn cultivation, and profession’s guard, decorate machine protection. Special welded wire mesh, (Heavy)welded wire mesh panel service as fencing mesh for transportation industry, construction a agriculture.

Surface treatment of of Welded Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Pvc coated welded wire mesh, (black wire mesh then pvc coated, electro gal. then pvc coated, hot dip gal. the pvc coated)

Advantage of Welded Wire Mesh

Our welded wire mesh has strong corrosion-resisting and oxidation-resisting with good quality and rock bottom price.

Packing of Welded Wire Mesh

1. Waterproof paper then PVC shrinking Film

2. PVC shrinking film only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

Pictures of Welded Wire Mesh

Specification of Welded Wire Mesh

Standard Welded Wire Mesh (in 30m length, Width of 0.5m-1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22-24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19-22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16-23 |

5/8" x 5/8" | 16mm x 16mm | 18-21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16-21 |

1" x 1/2" | 25.4mm x 12.7mm | 16-21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14-19 |

1" x 2" | 25.4mm x 50.8mm | 14-16 |

2" x 2" | 50.8mm x 50.8mm | 12-16 |

1/4" x 1/4" | 6.4mm x 6.4mm | 12-16 |

Welded Fencing Mesh (in 30m Length, Width of 0.5m -1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

2" x 3" | 50mm x 75mm | 1.65-2.5mm |

3" x 3" | 75mm x 756mm | 1.65-2.75mm |

2" x 4" | 50mm x 100mm | 2.1-2.9mm |

4" x 4" | 100mm x 100mm | 2.0mm,2.5mm |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Can steel wire mesh be used for creating storage racks or shelves?

- Indeed, storage racks or shelves can be created using steel wire mesh. Steel wire mesh is a flexible material that offers numerous benefits for storage purposes. Firstly, it possesses great strength and durability, enabling it to withstand heavy loads and resist bending or warping over time. This makes it ideal for the storage of heavy items or materials. Moreover, steel wire mesh is highly adaptable when it comes to design and customization. It is easily cut and manipulated to fit specific dimensions or configurations, allowing for the creation of storage racks or shelves that are tailored to individual requirements. The open structure of wire mesh also ensures proper ventilation and visibility, making it perfect for storing items that need airflow or easy access. Additionally, steel wire mesh is resistant to corrosion and rust, making it suitable for both indoor and outdoor storage applications. This ensures that storage racks or shelves made from it will have a longer lifespan and maintain their structural integrity, even in challenging environments. Overall, steel wire mesh offers a cost-effective and efficient solution for the creation of storage racks or shelves. Its strength, versatility, and durability make it an exceptional choice for organizing and storing a wide array of items in various settings, such as homes, warehouses, retail stores, and industrial facilities.

- Q: What are the different wire mesh strengths available in steel wire mesh?

- There are various different wire mesh strengths available in steel wire mesh, which are determined by the thickness and type of wire used. Steel wire mesh is typically categorized into three main strength levels: light, medium, and heavy-duty. Light-duty steel wire mesh is commonly used for applications that require minimal strength, such as decorative purposes or lightweight fencing. It is usually made with thinner wires, typically ranging from 0.5mm to 1.2mm in diameter. Despite its lower strength, light-duty steel wire mesh still provides adequate support and durability for its intended uses. Medium-duty steel wire mesh offers a stronger option compared to light-duty mesh. It is commonly utilized in applications that require a moderate level of strength, such as security screens, animal enclosures, or reinforcement in concrete structures. The wire diameter for medium-duty mesh usually ranges from 1.2mm to 2.5mm, providing increased stability and resistance to deformation. For more demanding applications that require high strength and durability, heavy-duty steel wire mesh is the ideal choice. It is commonly used in industrial settings, construction projects, or areas with heavy loads or impacts. Heavy-duty mesh is made with thicker wires, typically ranging from 2.5mm to 6mm in diameter. This ensures exceptional strength, rigidity, and resistance to bending or breaking under intense pressure. It is important to note that wire mesh strength can also be influenced by factors such as the spacing between wires and the weave pattern used. Different configurations, such as square mesh or welded mesh, can affect the overall strength and performance of steel wire mesh. When selecting the appropriate wire mesh strength for a specific application, it is crucial to consider the intended purpose, expected load or pressure, and environmental conditions. Consulting with a knowledgeable supplier or expert can provide valuable guidance in choosing the right strength level to ensure optimal performance and longevity of the steel wire mesh.

- Q: How is steel wire mesh used in reinforcement of roadways?

- Steel wire mesh is widely utilized to strengthen and enhance the durability of roadways. Comprising interconnected steel wires arranged in a grid-like pattern, the mesh is integrated into the layers of road construction. One of the primary functions of steel wire mesh is to evenly distribute the load across the surface of the road. Vehicles exert significant weight and pressure when passing over the road, which can cause cracks or deformations in the absence of reinforcement. The steel wire mesh helps distribute the weight and stress evenly, thereby preventing the formation of cracks or potholes. Furthermore, steel wire mesh aids in controlling and preventing the spread of cracks that naturally occur in roadways due to external factors such as temperature changes or ground movements. By providing continuous support, the mesh limits the movement of the road material, reducing the likelihood of cracks extending and minimizing the need for expensive repairs. Additionally, steel wire mesh enhances the overall stability of road construction by improving the tensile strength of the road material. This allows it to withstand greater forces and resist deformation, particularly in areas with heavy traffic or adverse weather conditions. In addition to its reinforcement properties, steel wire mesh contributes to the longevity of roadways. By preventing cracks and deformations, it extends the lifespan of the road, reducing the frequency of maintenance and repairs. This not only saves costs but also minimizes disruptions to traffic flow. In conclusion, steel wire mesh plays a crucial role in reinforcing roadways by distributing loads, controlling crack propagation, enhancing stability, and increasing longevity. Its incorporation in road construction ensures safer and more durable road surfaces, benefiting both drivers and the transportation infrastructure as a whole.

- Q: What are the benefits of using steel wire mesh in the textile refurbishing industry?

- Steel wire mesh is a versatile material that offers numerous benefits in the textile refurbishing industry. Firstly, it provides a strong and durable support structure for fabrics during the refurbishing process. This is particularly important when handling delicate or fragile textiles, as the steel wire mesh prevents damage and distortion while the fabric is being worked on. Additionally, steel wire mesh allows for better airflow and ventilation during the refurbishing process. This is crucial for drying fabrics, as it helps to prevent the growth of mold and mildew. The open structure of the mesh also facilitates the application of chemicals or dyes, ensuring an even and consistent distribution. Another advantage of using steel wire mesh is its resistance to corrosion and wear. This makes it suitable for use in wet or humid environments, as well as in situations where fabrics may come into contact with chemicals or cleaning agents. Steel wire mesh is also easy to clean and maintain, ensuring longevity and cost-effectiveness for textile refurbishing businesses. Moreover, steel wire mesh offers excellent stability and support for stretching fabrics during the refurbishing process. This is particularly important when working with curtains, upholstery, or other textiles that require precise measurements and alignment. The mesh's strength and rigidity ensure that fabrics can be stretched and secured evenly, resulting in a professional and polished finish. Lastly, steel wire mesh is a sustainable choice for the textile refurbishing industry. It is a recyclable material, reducing waste and environmental impact. By using steel wire mesh, textile refurbishing businesses can contribute to a more sustainable and eco-friendly approach to their operations. In conclusion, the benefits of using steel wire mesh in the textile refurbishing industry are numerous. It provides strength, durability, and stability to fabrics, allows for better airflow and ventilation, resists corrosion and wear, offers easy maintenance, and contributes to sustainability. Incorporating steel wire mesh into textile refurbishing processes can greatly enhance the efficiency, quality, and longevity of the finished products.

- Q: What are the different mesh configurations available for steel wire mesh?

- Steel wire mesh offers a range of mesh configurations to suit specific applications and requirements. Here are some common examples: 1. Square Mesh: The wires are woven together in a square pattern, creating equal-sized square openings. It is known for its strength and stability. 2. Rectangular Mesh: Similar to square mesh, but with rectangular openings. This configuration offers greater flexibility and is ideal for applications requiring a higher flow rate or larger particle retention. 3. Dutch Weave Mesh: The warp wires are smaller in diameter than the weft wires, resulting in a tighter weave with smaller openings. This configuration excels in filtering fine particles. 4. Twilled Weave Mesh: A variation of the plain square weave, where the weft wires pass over and under two warp wires. This creates a diagonal pattern, making the mesh stronger with higher tensile strength. 5. Reverse Dutch Weave Mesh: The opposite of Dutch weave mesh, with larger diameter warp wires. It is commonly used for high-pressure filtration due to its exceptional strength and filtration efficiency. 6. Welded Mesh: Intersecting wires are spot welded together, offering high strength and durability. It finds applications in fencing, reinforcement, and concrete reinforcement. 7. Expanded Metal Mesh: A sheet of metal is cut and stretched to create diamond-shaped openings with raised strands. It provides excellent ventilation and visibility, and is commonly used for security, architecture, and grating. These examples showcase the diverse options available in steel wire mesh. The choice of configuration depends on factors such as the intended application, required strength, filtration needs, and aesthetic preferences.

- Q: How is steel wire mesh used in animal enclosures?

- Due to its strength and durability, steel wire mesh is frequently utilized in animal enclosures. This mesh offers a secure barrier that effectively prevents animals from escaping, while still allowing for proper ventilation and visibility. Within zoos and wildlife reserves, steel wire mesh is employed to construct enclosures for a diverse range of animals. These enclosures cater to small birds, reptiles, and even large mammals. The mesh is meticulously woven to ensure that small animals cannot squeeze through, guaranteeing their safety. In agricultural settings, such as poultry farms and livestock enclosures, steel wire mesh finds extensive use. Farmers utilize it to craft pens and cages that confine and protect animals from predators. The mesh enables easy monitoring of the animals and provides a safe environment for them to freely move and graze. Moreover, steel wire mesh is widely employed in pet enclosures and kennels. It is commonly found in dog runs and outdoor cat enclosures, offering a secure and spacious area for pets to engage in exercise and play. The mesh's robustness withstands scratching and chewing, ensuring that pets remain contained and safe. Overall, steel wire mesh serves as a versatile material for animal enclosures. Its strength, durability, and flexibility make it an ideal choice for constructing secure and comfortable habitats for a wide array of animals, ranging from small pets to large wildlife.

- Q: What are the anti-slip properties of steel wire mesh?

- Steel wire mesh has excellent anti-slip properties due to its textured surface and high coefficient of friction. The interwoven wire strands create a rough and stable surface, providing a secure grip for pedestrians and vehicles, even in wet or slippery conditions.

- Q: What are the electrical resistance properties of steel wire mesh?

- The electrical resistance properties of steel wire mesh depend on factors such as the thickness of the wire, the spacing between the wires, and the conductivity of the steel used. Generally, steel wire mesh has low electrical resistance due to the high conductivity of steel. However, the resistance can vary depending on the specific characteristics of the mesh.

- Q: How is steel wire mesh used in the automotive aftermarket industry?

- Steel wire mesh is commonly used in the automotive aftermarket industry for a variety of purposes. One of the main applications of steel wire mesh is in car grilles. These grilles are responsible for protecting the car's front end, particularly the radiator, from debris and other potential damage. Steel wire mesh is used in the construction of these grilles due to its high strength and durability. Steel wire mesh is also used in the production of car seat covers. The mesh is woven tightly to create a breathable and comfortable surface for the driver and passengers. This allows air to circulate and reduces the discomfort caused by sitting in a car for long periods of time. Additionally, steel wire mesh is utilized in the production of filters for various automotive components. These filters play a crucial role in maintaining the performance and longevity of different systems in a vehicle, such as the air intake system, oil filtration, and fuel filtration. The steel wire mesh used in these filters helps to trap and prevent contaminants from entering and damaging the internal components of the automotive systems. In the automotive aftermarket industry, steel wire mesh is also used for customizing vehicles. It can be used to create unique and visually appealing designs, such as mesh grilles, body panels, or even speaker covers. Its versatility and ability to be easily shaped and molded make it a popular choice for car enthusiasts looking to enhance the aesthetics of their vehicles. Overall, steel wire mesh is an essential component in the automotive aftermarket industry. It is used for various applications, including grille production, seat covers, filters, and customization. Its strength, durability, and versatility make it an ideal material for enhancing both the functionality and appearance of vehicles.

- Q: How does steel wire mesh perform in high-humidity environments?

- Due to its inherent properties and durability, steel wire mesh is highly effective in high-humidity environments. Its resistance to corrosion, a well-known characteristic of steel, makes it a suitable material for wet and humid conditions. To enhance its resistance to moisture and prevent rusting, the wire mesh is typically galvanized or coated with a protective layer. Steel wire mesh maintains its structural integrity and strength in high-humidity environments. It remains unaffected by warping, deformation, or loss of shape, ensuring consistent performance over time. The mesh's open design allows for proper ventilation and airflow, preventing the accumulation of moisture that could result in condensation or mold growth. In various industries such as construction, agriculture, and manufacturing, steel wire mesh is commonly used in applications exposed to high humidity levels. These applications include concrete reinforcement, fencing, animal enclosures, and filtration systems. While steel wire mesh generally exhibits resilience in high-humidity environments, it is crucial to choose the appropriate grade and coating that suits the specific conditions. This ensures optimal performance and extends the mesh's lifespan. Regular maintenance and cleaning are also necessary to remove any accumulated debris or moisture, thereby preserving its functionality and appearance.

Send your message to us

Welded Wire Mesh in Building Construction -1/2 X 1

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords