Welded Wire Mesh Fence 1/2 Inch

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Sets set

- Supply Capability:

- 10000 Square Meters per Week set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

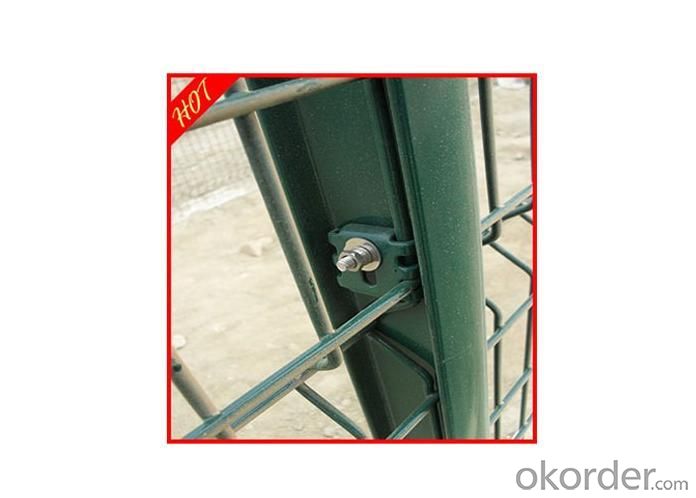

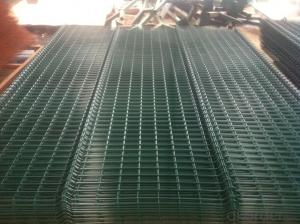

1/2-inch welded wire mesh fence

anti-corrosion waterproof

50mmx100,50x200,75x150 etc.

ISO9001/2000

wire mesh fence

1.wire mesh fence detailed descripition

wire mesh fence is also known as welded wire mesh fence,welded fences or welded fencing.This fence is pretty light yet durable,its composition is simply wire welded together to make a fece.The welds are fairly strong.

2.Material:

Low carbon steel wire,galvanized wire,aluminum alloy wire,stainless steel wire

3.Fence is a freestanding structure designed to restrict or prevent movement across a boundary.

Fence are constructed for several purposes.including:

1.) Agricultural fencing: to keep livestock in or predators act.

2.) Temporary fencing: to provide safety and security and to direct movement.wherever temporary access control is required,especially on building and construction sites.

3.)Boundary fencing: to demarcate a piece of real property.

4.) Barbed wire fence: can be made in different styles as per requirement,like for agricultural pruposes.protecting livestock,demaring property, etc

5.) Chain link fencing: is most commonly available galvanized which is silver color. We also carry colored chain link fence.

- Q: Main ingredients and formulations of PPR tubes

- PP-R (polypropylene, random) tubes are also called type three polypropylene tubes and also called random copolymerized polypropylene tubes or PPR tubes. The main component is polypropylene three. The formula is different for each manufacturer. This ratio requires manufacturers to do experiments many times before they can be certain.

- Q: Plastic PPT30S add what material will increase hardness?

- In general, this material will be grafted with PP-G, POE, increase the impact, plus stone powder, glass fiber, mica powder, increase hardness.

- Q: What is the hardness of PAEK+30%GF plastic material?

- The German mineralogist 7 (F.Mohs) from nature ten minerals commonly used as the standard, the hardness is divided into 1 degrees to 10 degrees ten grades, namely Moss hardness standard (Mohs Hardness), also known as the Moss hardness (Mohs hardness).Mohs hardness used to express the performance characterization of mineral mutual abrasion resistant ability.

- Q: What are the raw materials for making plastics?

- 1. the main component of plastic raw material is resin2: plastic raw material is made of polymer synthetic resin (polymer) as the main ingredients penetrate various auxiliary materials or additives, in particular temperature, has the plasticity and fluidity under pressure, can be molded into shape and maintain the same shape of material under certain conditions.

- Q: How to make plastic raw materials?

- oil refiningPetroleum crackingCracking is the process of breaking down hydrocarbons with relatively large molecular weight and high boiling point under certain conditions, which are relatively small molecular weight and low boiling point hydrocarbons.Cracking under catalysis, also known as catalytic cracking.

- Q: What is plastic film material?

- The material is plastic particles. Polyethylene film is used for polyethylene particles; polypropylene film is polypropylene particles. Some of the films are blown out of film blowing machines; some are cast films and pressed out of the machine.

- Q: What is Ms plastic material?

- The utility model has the advantages of good transparency, optical property, low moisture absorption, good weather resistance, easy processing, and residual stress of formed products... Other characteristics. Moreover, the proportion of MS resin is lower than acrylic, and the cost is cheaper.General injection molding and extrusion molding, transparent to acrylic resin (PMMA)

- Q: How do plastic materials come from?

- Polymer: any of the pure or polymeric materials produced by the polymerization process, whether natural or synthetic resins, are polymers, polymers, or polymers

- Q: What kind of raw material is plastic hollow board made of?

- Plastic hollow board products widely, can produce hollow board turnover box, hollow board, hollow plate knife clapboard, anti-static hollow board, conductive plastic hollow board products. Multi use in electronic products turnover and handling, warehousing and so on. In addition to the production of flame retardant plastic hollow board, plastic plastic hollow board, back board, magnetic refrigerator with black and white writing board, backplane cloth cabinet inside the closet board and other plastic products.

- Q: What are the raw materials for producing plastic vest bags?

- The time required for plate making is usually about 5 days, and can be rented from a plate factory.Borrowed is printedPlastic vest bag printing is generally relatively simple, color is not complicated, simple and concise.And then there's the cutSealing and cutting are sealing and hollowing of printed material, and also the last step in forming waistcoat bags.Now, the advanced sealing machine is one step, without punching and hollowing.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2005 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Oceania Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | HACCP ;ISO 9001:2000 ;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | tianjin,huanghua,ningbo |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, French |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Welded Wire Mesh Fence 1/2 Inch

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Sets set

- Supply Capability:

- 10000 Square Meters per Week set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords