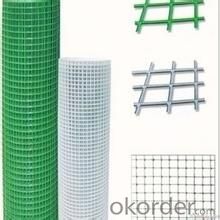

PVC Welded Wire Mesh for Ceiling-1-1/2 X 1-1/2

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Welded Wire Mesh

Welded Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire, PVC coated iron wire in blue, green, yellow and other colors.

Application of Welded Wire Mesh

Galvanized welded wire mesh, PVC coated welded wire mesh for garden, feeding agriculture, fishing, poultry, mine field, lawn cultivation, and profession’s guard, decorate machine protection. Special welded wire mesh, (Heavy)welded wire mesh panel service as fencing mesh for transportation industry, construction a agriculture.

Surface treatment of of Welded Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Pvc coated welded wire mesh, (black wire mesh then pvc coated, electro gal. then pvc coated, hot dip gal. the pvc coated)

Advantage of Welded Wire Mesh

Our welded wire mesh has strong corrosion-resisting and oxidation-resisting with good quality and rock bottom price.

Packing of Welded Wire Mesh

1. Waterproof paper then PVC shrinking Film

2. PVC shrinking film only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

Pictures of Welded Wire Mesh

Specification of Welded Wire Mesh

Standard Welded Wire Mesh (in 30m length, Width of 0.5m-1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22-24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19-22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16-23 |

5/8" x 5/8" | 16mm x 16mm | 18-21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16-21 |

1" x 1/2" | 25.4mm x 12.7mm | 16-21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14-19 |

1" x 2" | 25.4mm x 50.8mm | 14-16 |

2" x 2" | 50.8mm x 50.8mm | 12-16 |

1/4" x 1/4" | 6.4mm x 6.4mm | 12-16 |

Welded Fencing Mesh (in 30m Length, Width of 0.5m -1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

2" x 3" | 50mm x 75mm | 1.65-2.5mm |

3" x 3" | 75mm x 756mm | 1.65-2.75mm |

2" x 4" | 50mm x 100mm | 2.1-2.9mm |

4" x 4" | 100mm x 100mm | 2.0mm,2.5mm |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Can steel wire mesh be used for retaining rock walls?

- Yes, steel wire mesh can be used for retaining rock walls. Steel wire mesh is commonly used in various construction applications, including retaining walls. When properly installed, it provides additional support and stability to the rock wall by acting as a reinforcement. The wire mesh helps to prevent the rocks from shifting or sliding, enhancing the overall strength and durability of the wall. Additionally, steel wire mesh is resistant to corrosion, making it a suitable choice for outdoor applications where it may be exposed to moisture and other environmental factors.

- Q: The problem of setting up the wire mesh above the warm coil

- Steel wire mesh is mainly to prevent the ground cracking. If you are tiles, marble floor, you can not shop steel mesh. If you prepare the shop composite floor, it is still a layer of steel mesh as well. Directly to the network shop in the geothermal coil, steel wire is not afraid to step on.

- Q: Does steel wire mesh rust?

- Yes, steel wire mesh can rust. Rust is the result of the oxidation process that occurs when iron or steel is exposed to moisture and oxygen. If the steel wire mesh is not properly coated or protected, it can be susceptible to rusting over time. However, there are various methods to prevent or minimize rusting, such as galvanizing the steel wire mesh or applying a protective coating. These measures can significantly extend the lifespan of the mesh and ensure its durability.

- Q: Can steel wire mesh be used for reinforcement?

- Yes, steel wire mesh can be used for reinforcement in various applications. Steel wire mesh is commonly used in construction projects to reinforce concrete structures such as walls, slabs, and foundations. It helps to enhance the strength and durability of the concrete by providing additional support and preventing cracking or breaking under pressure. Steel wire mesh is also used in road and pavement construction to reinforce the asphalt and prevent the formation of cracks. Additionally, it is used in the manufacturing of fences, cages, and other industrial applications where strength and durability are required. Overall, steel wire mesh is an effective and widely used material for reinforcement purposes.

- Q: Can steel wire mesh withstand high temperatures?

- Yes, steel wire mesh can withstand high temperatures. Steel wire mesh is typically made from stainless steel or carbon steel, both of which have high melting points and excellent heat resistance properties. Stainless steel wire mesh can withstand temperatures up to 800-900 degrees Celsius (1472-1652 degrees Fahrenheit), while carbon steel wire mesh can withstand temperatures up to 450-500 degrees Celsius (842-932 degrees Fahrenheit). This makes steel wire mesh suitable for applications that involve high temperatures, such as industrial furnaces, kilns, and heat treatment processes. However, it is important to note that the specific temperature resistance of steel wire mesh may vary depending on the grade and quality of the steel used, as well as the specific manufacturing process. Therefore, it is recommended to consult the manufacturer or supplier for precise temperature ratings and suitability for specific high-temperature applications.

- Q: Can steel wire mesh be used for waste bins?

- Certainly, waste bins can indeed utilize steel wire mesh. Steel wire mesh, a versatile material with numerous advantages for waste bins, offers durability and longevity due to its sturdy construction. This attribute makes it suitable for heavy-duty waste management applications. In addition, the mesh's open design allows for proper ventilation, preventing the accumulation of odors and reducing the chances of bacterial growth. Moreover, the mesh's holes enable easy visibility of the waste contents, facilitating the identification and sorting of recyclable materials. Furthermore, steel wire mesh is resistant to rust and corrosion, rendering it suitable for both indoor and outdoor use. In summary, steel wire mesh is a practical and functional option for waste bins, delivering strength, ventilation, and visibility.

- Q: How does steel wire mesh compare to other types of mesh?

- Steel wire mesh is widely recognized as one of the most versatile and durable mesh options on the market. It boasts several advantages over alternative mesh varieties, making it a top choice for a variety of applications. To begin with, steel wire mesh is renowned for its exceptional strength and durability. The high tensile strength of steel enables it to withstand heavy loads and resist deformation, making it ideal for applications that require robust support or protection. Unlike other mesh types, steel wire mesh is highly resistant to breakage or damage, even in extreme conditions, ensuring long-lasting performance. Additionally, steel wire mesh offers excellent resistance to corrosion. This characteristic is particularly crucial in outdoor or high-moisture environments where other meshes, such as aluminum or plastic, may corrode or deteriorate over time. The corrosion-resistant properties of steel wire mesh make it a reliable choice for applications that require longevity and dependability. Moreover, steel wire mesh provides superior security and protection. Its sturdy construction and interlocking design make it challenging to cut or break, making it an ideal option for fencing, enclosures, or other security applications. Compared to alternative mesh types, steel wire mesh offers increased resistance to vandalism or unauthorized access, ensuring the safety and security of the protected area. Furthermore, steel wire mesh offers excellent visibility and airflow. Thanks to its open design, steel wire mesh allows for maximum visibility, making it suitable for applications that require an unobstructed line of sight, such as architectural design or safety enclosures. The open structure also promotes airflow, proving advantageous in applications that necessitate ventilation or temperature control. Lastly, steel wire mesh is highly adaptable and can be customized to meet specific requirements. Available in various mesh sizes, wire diameters, and configurations, steel wire mesh allows for flexibility in design and functionality. This adaptability renders steel wire mesh suitable for a wide range of applications, including construction, mining, agriculture, filtration, and many others. In conclusion, steel wire mesh is unparalleled when compared to alternative mesh types, given its exceptional strength, corrosion resistance, security, visibility, airflow, and versatility. These characteristics establish steel wire mesh as the preferred choice for applications that demand durability, longevity, and reliable performance.

- Q: How is steel wire mesh used in reinforcement of manufacturing facilities?

- Steel wire mesh is commonly used in the reinforcement of manufacturing facilities for various purposes. One of the primary uses is in concrete reinforcement. Steel wire mesh is embedded within the concrete structure to enhance its structural integrity and increase its load-bearing capacity. This is particularly crucial in manufacturing facilities where heavy machinery and equipment are utilized, as it helps prevent cracking, sagging, and failure of concrete structures. Steel wire mesh is also used in the reinforcement of walls and partitions within manufacturing facilities. It provides added strength and stability, ensuring that the walls can withstand external forces and pressures. This is important in facilities where there are high vibrations or potential impacts, such as from heavy machinery or forklift movements. Moreover, steel wire mesh is used for safety purposes in manufacturing facilities. It can be installed as a protective barrier around hazardous areas or machinery to prevent accidents and injuries. Steel wire mesh acts as a physical barrier, allowing visibility and ventilation while restricting access to dangerous areas. Additionally, steel wire mesh is utilized in the reinforcement of storage racks and shelves within manufacturing facilities. By incorporating wire mesh panels or decking, the structural integrity of these storage systems is improved, allowing for the safe and efficient storage of heavy items and materials. Overall, steel wire mesh is an essential component in the reinforcement of manufacturing facilities. Its versatility, durability, and strength make it an ideal choice for enhancing the structural integrity of concrete, walls, partitions, storage systems, and providing safety measures, ensuring a safe and efficient working environment in manufacturing facilities.

- Q: Is steel wire mesh suitable for marine applications?

- Yes, steel wire mesh is suitable for marine applications. It is highly durable, corrosion-resistant, and can withstand the harsh conditions of saltwater environments. Additionally, steel wire mesh offers excellent strength and structural integrity, making it ideal for various marine applications such as fencing, filtration, and reinforcement.

- Q: Is steel wire mesh suitable for use in automotive airbag systems?

- No, steel wire mesh is not suitable for use in automotive airbag systems. Airbag systems require materials that are lightweight, flexible, and have high tensile strength. Steel wire mesh is heavy, rigid, and may not provide the necessary level of flexibility required for airbags to properly deploy and protect occupants in the event of a collision. Additionally, steel wire mesh may not offer the same level of impact absorption as other materials used in airbag systems, potentially compromising the safety of the vehicle occupants. Therefore, alternative materials such as nylon or polyester fabric are commonly used in automotive airbag systems due to their lightweight, flexible, and high tensile strength properties.

Send your message to us

PVC Welded Wire Mesh for Ceiling-1-1/2 X 1-1/2

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords