Weldable EPDM Waterproof Sheet Width1~4m Thickness 1.2mm~2.0mm for Basement Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 220000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Weldable EPDM Rubber Waterproof Membrane

Product Instruction:

Durability and ease of installation are two of the key reasons . Single ply EPDM Roof systems are becoming commonplace in today flat roofing market. EPDM membrane is a flexible rubber material available in 45 mil, 60 mil and 90 mil thicknesses. With its superior flexibility, resistance to fire and high strength, EPDM can be applied in all sorts of climates.

Weldable EPDM waterproof membrane is made from ternary ethylene-propylene rubber,which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

CNBM own the wold-advanced equipment of cold feeding extrusion and continuous vulcanization technology. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or cracked under normal building movement.

Product Features:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications:

-Basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications:

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

-Type: vulcanized EPDM or welding EPDM

-Application: roof, basement, pond, lake, swimming pool, steel structure roofing, underground, tunnel, etc

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

6. How long do we usually reply your request?

We always reply our customer within 24 hours.

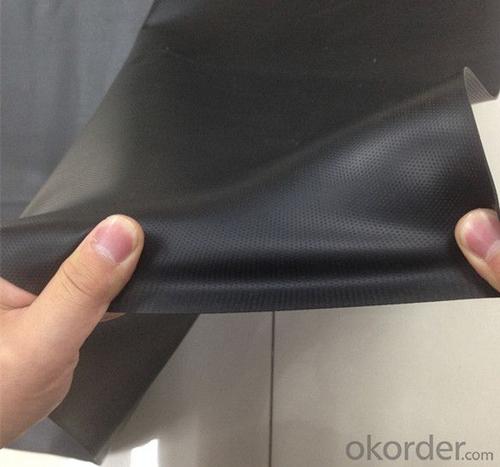

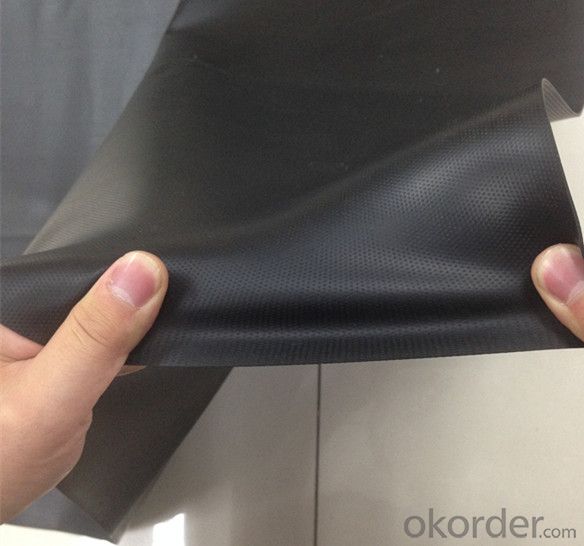

Photos:

- Q: Can a waterproofing membrane be used on balconies and decks?

- Yes, a waterproofing membrane can be used on balconies and decks. Waterproofing membranes are specifically designed to provide a protective layer against water damage, making them an ideal solution for outdoor areas like balconies and decks that are exposed to rain, snow, and other moisture. By applying a waterproofing membrane, you can effectively prevent water penetration, enhance the durability of the surface, and extend the lifespan of your balcony or deck.

- Q: Polyurethane and SBS membrane waterproof

- ?Methyl methacrylate (methyl acrylate), acrylamide (acrylic), polyurethane (cyanide) as the base material of the grouting material can be used for underground engineering plugging waterproof. ?Because plastic in the sun is easy to aging, so used in underground engineering, and polyurethane can be made of liquid, used to plug the water.

- Q: Can a waterproofing membrane be installed by a homeowner or is professional installation necessary?

- Professional installation is typically recommended for waterproofing membrane installation. This is because proper installation requires specialized knowledge, skills, and equipment to ensure the membrane is correctly applied and effectively waterproofs the intended area. Hiring a professional ensures that the installation is done correctly and reduces the risk of potential water damage in the future.

- Q: Can a waterproofing membrane be used for underwater structures?

- Yes, a waterproofing membrane can be used for underwater structures. Waterproofing membranes are designed to provide a barrier against water penetration, which makes them suitable for use in underwater applications. They are commonly used in the construction and maintenance of structures such as swimming pools, submarines, offshore platforms, and underwater tunnels to prevent water leakage and protect against corrosion.

- Q: Pvc waterproof membrane of the scope of application

- 6, light color of the surface reflection of ultraviolet radiation, the surface of the membrane to absorb less heat, low temperature; 7, long life (roof 25 years, more than 50 years underground), and no environmental pollution; 8, the details of processing is very convenient, easy maintenance, low cost.

- Q: Can a waterproofing membrane be used for warehouses or storage facilities?

- Warehouses or storage facilities can utilize a waterproofing membrane. These membranes are specifically designed to safeguard structures against water damage by creating a barrier that prevents moisture infiltration. In warehouses and storage facilities, there are often large areas that are vulnerable to potential leaks or seepage, such as roofs, walls, and floors. By installing a waterproofing membrane, these structures can be effectively shielded from water intrusion, thereby preventing harm to stored goods and maintaining the facility's integrity. Waterproofing membranes come in various types, including bituminous, liquid-applied, or sheet membranes, providing flexibility in selecting the most appropriate option based on the specific requirements of the warehouse or storage facility. Furthermore, waterproofing membranes offer additional advantages such as thermal insulation and resistance to chemicals, further enhancing their value in ensuring the durability and functionality of warehouses or storage facilities.

- Q: Can a waterproofing membrane be used for a tunnel lining?

- Indeed, a tunnel lining can utilize a waterproofing membrane. This membrane functions as a barrier, explicitly crafted to impede water infiltration and safeguard the structure from moisture-induced harm. Its application to the inner surface of the tunnel effectively seals and waterproofs the lining, thereby thwarting water ingress. This, in turn, prevents the onset of corrosion, deterioration, and structural complications that could arise over time. Moreover, the waterproofing membrane also acts as a protective shield against other potential issues, such as chemical attacks, groundwater pressure, and freeze-thaw cycles. To ensure suitability for tunnel applications, it is imperative to opt for a waterproofing membrane specifically designed to withstand the distinctive conditions and demands of tunnels, including high water pressure and possible movement. Regular inspections and maintenance play a vital role in guaranteeing the long-term efficacy of the waterproofing membrane within a tunnel lining.

- Q: Can a waterproofing membrane be used for roofing applications?

- Indeed, a waterproofing membrane can be utilized in roofing applications. Specifically designed to create a barrier against water infiltration, waterproofing membranes are commonly employed in a range of construction projects, including roofs. These membranes typically consist of durable materials like synthetic rubber, thermoplastics, or modified bitumen, renowned for their water-resistant properties and longevity. By installing a waterproofing membrane on the roof, one can effectively safeguard the building from water leaks and moisture penetration, which may result in structural damage, mold growth, and other related problems. The membrane is typically applied seamlessly onto the roof surface, forming a watertight layer that prevents water from permeating through. Waterproofing membranes for roofing applications are available in various types, such as sheet membranes, liquid or spray-applied membranes, or self-adhering membranes. Each type offers distinct advantages and suitability depending on the specific roofing requirements and construction conditions. In conclusion, a waterproofing membrane is indeed a viable choice for roofing applications, providing an efficient solution to ensure a durable and watertight roof system.

- Q: Can a waterproofing membrane be used in bathrooms?

- Yes, a waterproofing membrane can be used in bathrooms. In fact, it is highly recommended to use a waterproofing membrane in bathrooms to prevent water damage and leakage. The membrane is typically applied on the walls and floors, creating a barrier that prevents water from seeping through and causing structural damage or mold growth. This is especially important in areas such as showers and around bathtubs where water exposure is high. Waterproofing membranes are designed to withstand moisture and provide long-lasting protection, ensuring the integrity of the bathroom and extending its lifespan.

- Q: Can a waterproofing membrane be used on gypsum block surfaces?

- Yes, a waterproofing membrane can be used on gypsum block surfaces. Gypsum blocks are porous and can be prone to moisture infiltration, so applying a waterproofing membrane can help prevent water damage and moisture-related issues.

Send your message to us

Weldable EPDM Waterproof Sheet Width1~4m Thickness 1.2mm~2.0mm for Basement Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 220000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords