Customized Fiber Cement Board / External Wall Board / Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

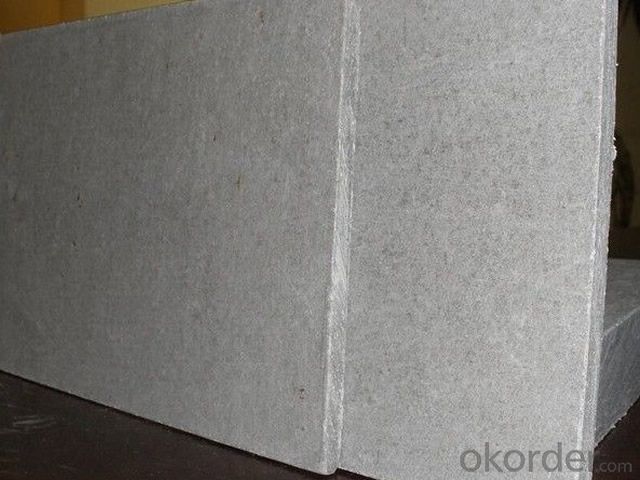

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

Main Product Features:

It's 100% free of asbestos, formaldehyde, benzene and other harmful substances and with excellent performance like high strength, large size, light weight, fire and water proofing, green and environmental friendly, high efficient and energy-saving. Therefore, this kind of new material is vigorously developed and recommended by the country.

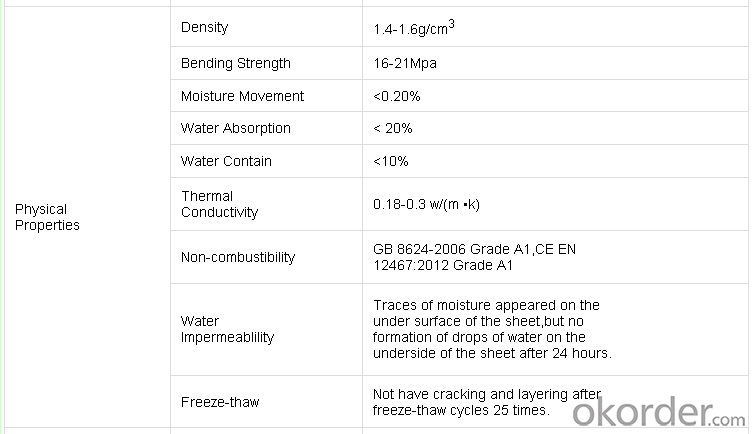

Product Specifications:

FAQ:

1. Which port do you choose for FOB ?

Answer: FOB Shanghai Port.

2. What's your delivery time of your products?

Answer: About 20 days after confirm the order.

3. What about the terms of payment?

Answer: 30%TT advanced payment, balance seven days before shipment.

Other terms of payments also can be negotiated.

4. What's your Minimum order quantity(MOQ) of your product?

Answer: Generally, MOQ is 1x20' container. Others can contact with me directly.

Images:

- Q: Cement pressure plate to do the bathroom partition, strength and humidity can meet the requirements?

- Cement fiber reinforced pressure plate to do a good partition, the strength of toughness have, construction fast, and the keel can be fixed after the board to do any decoration Oh

- Q: I think I have termites outside on my shield. I sprayed that terminix on the shield but now there are some holes that I want to cover up and since I had extra durock cement board I put it up to help keep any water or anything from going in. Is this a good idea and will the cement board be ok in the weather of the San Jose ca area.

- It isn't the termites you see that matter, it is the many more that remain hidden. Get a proper inspection before making any changes.

- Q: Plywood, gypsum board, cement board, aluminum-plastic board, which to choose, why?

- Cement board, plywood can do partition, gypsum board, plywood can do ceiling. Aluminum-plastic panels are only decorated with the surface, both can be. Cement board strength is good, but the weight is large, suitable for partition board; gypsum board has several kinds, there are partitions with a plate with a ceiling. There are several plywood, the general 3 to 5 plywood can do decorative panels of the grassroots, there are thick plywood can be used to do partition.

- Q: Factory roof directly painted on the cement board directly spray the white again

- Do not require a full cover, and so spray the paint does not stick and then spray. Several spray can be completely covered.

- Q: or add visquine on top of the plywood and then put on the backer board

- no. unless the floor is very uneven

- Q: How does the cement pressure plate interface

- The foot line: also called "baseboard". Generally refers to the decorative lines installed on the wall above the floor.

- Q: I've done the hard way - bunches of expensive special screws. I found that to be expensive and time consuming (and therefore back breaking). It seems like it takes just as long to do the backer board as it does to do all the remaining steps with the tile. Can I use nails? If so, what kind? Thinset and nails? The subfloor is plywood with old vinyl tiles, I have no intention of remove the old vinyl tiles first. Please reply if you have personal experience with an alternative. Thanks!

- If you want it to last you should thin set AND screw the cement board down. Cement board is not just used in wet areas. It is a dimensionally stable product and properly installed it will keep your tile and grout from cracking and/or coming loose. If you try to scimp on the prep then you will be wasting your time and money. Some installers do nail it down but bare in mind that this will void any warranty. Don't forget to tape the joints too. If the vinyl tiles are down tight and height room to room is not an issue then leave it in place and go over top.

- Q: Hi All,Basically what I am trying to say is that I have a wooden board which will be placed vertically on the floor and would be a decoration.I want to have a coating of cement of some sort on it and make some patterns on it.I like to know if it is possible to lay a thin coating layer of cement or even tile bond glue to a wooden board, lets say a timber board.basically anything that can give me the concrete/cement look as rough as that.. uld be any kind of cement or tiling glue or such...Thanks

- u can. but it will be easy to crack. if u want to put tile on it, use glue instead. i think.. :) good luck

- Q: I want to cut off a lip of about 1/8 by 1/2 to accomodate the upper lip of a tub. I plan to do this with several passes of an abrasive wheel in a circular saw set to 1/8. My question is will I be able to machine the board like this or will I get a crumbling mess? the Hardiback is 1/2.

- Its not like cutting tile. it will not be a clean cut.

- Q: I want a smoother cut than I will get by scoring and breaking. Would I use an abrasive wheel in a circular saw or a diamond blade?

- a diamond blade is good yes, but running it perfectly straight is the difficult part. Make your self a straight edge so your saw or angle grinder can rest against it as your cutting ( say the blade is 50mm from the saw base or angle grinder guard, put your straight edge 50mm away from your line) when it is cut get a piece of cement board and rub it along your cut to achieve a factory finish you could also buy a cement board blad ( it has only 4 teeth and it can fit onto your circular saw,) other then that you can use an angle grinder with a diamond blade.

Send your message to us

Customized Fiber Cement Board / External Wall Board / Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords