Vapor Barrier Membrane with PE Film and Non-Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vapor Barrier Membrane with PE Film and Non-Woven Fabric

Company Information:

We are located in National Development Zone in Nantong, with 22000 square meters area, including 7000 square meters dust free workshop.

We have equipped the most advanced pp non-woven production line and composite production lines including extrusion lamination production, hot melt lamination production line, calendar bonded production line with the technology from Italy and Germany, printing production line, cutting production line. We specialize in producing waterproof and breathable materials and heat insulation materials, pp non-woven fabric, disposable medical products, packaging materials and so on.

Products Information:

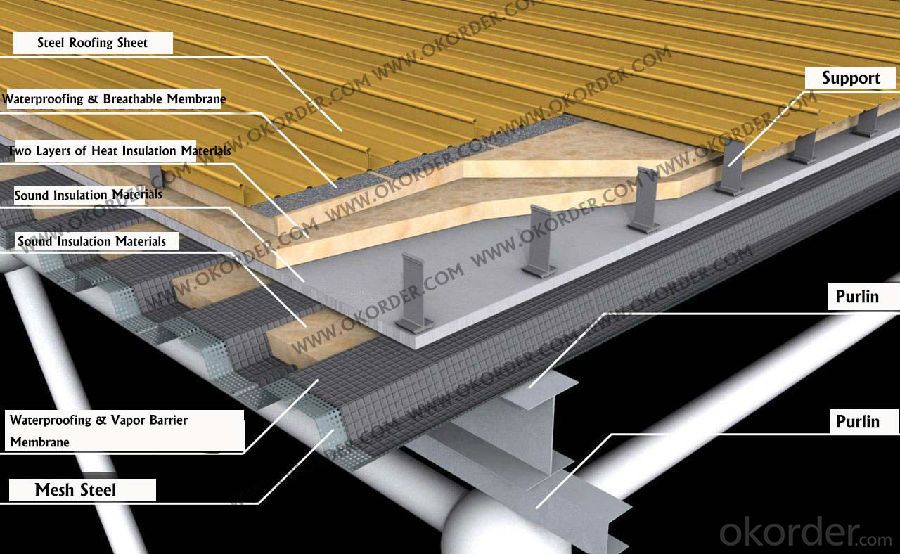

Vapor Barrier membrane is a roof membrane with three-layers, which is specially designed for application on ventilated pitched roofing, can be used under bituminous membrane as a extra protection for the attic insulation. It includes PET/PP non-woven fabric layer, PE/PP woven layer and aluminum foil layer. The three-layers structure ensure extreme resistance to tearing. Furthermore, the special stabilization additives ensure 3-month resistance to UV radiation.

Specifications:

Chemical Composition | PP & PE, Aluminum Foil, Woven Fabric |

Roll Size | 1.5meter*50meter |

Density: | 60gsm~130gsm |

Tensile Strength | MD:150N/50mm; CMD:115N/50mm |

Waterproofing Rate | W1 |

Vapor Resistant Rate | 6.9g/m2 ▪ 24h |

Aging rate under hot circumstance (90℃*168h) | MD:90%; CMD:100% |

Typical Application:

Container Loading:

FAQ:

1. Where is your factory located in?

Our factory is located in Jiangsu province, close to Shanghai.

2. Have you ever been export?

Yes, our product has been exported to many countries.

3. Can we get samples?

Yes, we are free for samples, what you need to assume is freight charge.

- Q: Slope roof drains do not need to be waterproof

- When installing a waterproof board, when the width of a waterproof board is not enough, to be placed side by side, it should be noted that the gap between the board and the plate will provide potential space for root growth.

- Q: What decoration materials, light and water, and the wall, the perfect combination of glass

- Between the glass and the wall is generally waterproof with waterproof glue, the specific steps are as follows: First, clean the surface Remove the surface of the joints of water, grease, dust and other pollutants, with a clean cloth to clean all the residue, so that the surface clean and dry. (If it is waterproof glue, the surface should be flat and clean, plastic gap to slightly curved as well.)

- Q: What material is used for waterproofing of tarpaulin

- Polypropylene Coil is only suitable for use in the top, waterproofing membrane is mainly used for building walls, roof, and tunnels, highways, landfills, etc., to resist the external rain, if it is home improvement Waterproof with this is not good, with tar ingredients, pollution of the environment.

- Q: Cabinet is to buy finished products, or directly to the decoration company to do?

- My home decoration cabinets are Haotian decorative package to do, although expensive, but still very worthwhile, all of their wood will be waterproof and moisture, in contact with the wall will do the underground waterproof and moisture, and are on-site cash Now do, timber materials can be seen directly, the amount of glue is not much, less formaldehyde, the latter part of the living is also more comfortable!

- Q: Roof membrane waterproof construction process, what should be noted that?

- Foundation treatment to find leveling to pay attention Five to: 1 slope accurate, smooth drainage 2 surface is flat 3 strong 4 clean 5 dry

- Q: Home improvement waterproofing problem

- 3, waterproof as to do more than 2 centimeters of closed water 24 hours or more closed water test, check whether there is leaking and dampness downstairs phenomenon.

- Q: How do you make waterproofing in the kitchen and bathroom?

- Kitchen and toilet is a relatively stable part of the home improvement structure, it is recommended to do waterproof mortar waterproofing agent on it, mortar waterproofing agent not only with the base surface bonding firm, and puncture resistance, high strength, waterproof life and construction Material with the life, the construction of relatively waterproof coating is also relatively simple. A barrel of 20KG mortar installed on the ground can be about 5 square feet, the wall can be done about 10 square feet, the price is relatively high. But to remind, must be in accordance with the product description on the process to match and construction, so as to ensure that once and for all the waterproof effect!

- Q: I would like to ask how to do in the warm water above,

- Do not know why you are in the floor to do the top of the waterproof? The We are here in the northeast of the winter is very cold, are warm, no one to warm the ground to do the above water, I think you over and over again, ah, no need, every family is warm, you have to do waterproof in the above is afraid of soaking your floor or tiles Bubble? The If the pipe really leaked, did not use the waterproof, the first warm tube must be selected, followed by your shop is good or bad, workers, water, are very important, you focus on this line on the line

- Q: Developers have done waterproof, decoration house also have to do it

- Secondly, before the waterproof layer may be done in the house decoration, paving tiles or other equipment when the installation was destroyed, so that the waterproof layer is no longer a whole,

- Q: Finished house bathroom waterproof household acceptance should be how to accept?

- 2: waterproof layer should be extended from the ground to the wall, 250mm above the ground. Bathroom wall waterproof layer height of not less than 1800mm.

Send your message to us

Vapor Barrier Membrane with PE Film and Non-Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords