Asphalt Roofing Felt(ASTM STANDART)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 Square Meter m²

- Supply Capability:

- 300000 Square Meter per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Specification of Asphalt Roofing Felt:

Item | Width | Length | Weight | Thickness | Usage |

ASTM D-226 roofing felt 30# | 36in 0.914m | 72ft 21.95 m | 23.5kg | 1.2mm | A roofing felt used as an underlay beneath asphalt shingles, wood shakes, tiles and other sloped coverings. |

ASTM D-226 roofing felt 15# | 36in 0.914 m | 144ft 43.89 m | 23kg | 0.8mm | |

ASTM D-4869 roofing felt 15# | 36in 0.914m | 144ft 43.89m | 16.5kg | 0.6mm | |

ASTM D-4869 roofing felt 30# | 36in 0.914m | 72ft 21.95m | 13.5kg | 0.8mm |

A heavy-weight Asphalt Roofing Felt made of a specially formulated organic sheet which has been fully saturated with waterproofing asphalt.

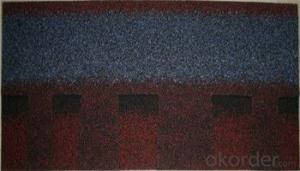

Pictures of Asphalt Roofing Felt:

Use of Asphalt Roofing Felt:

A roofing felt used as an underlay beneath asphalt shingles, wood shakes, tiles and other sloped coverings.

- Q: How to ensure the waterproof quality of the underground shear wall (retaining wall)?

- 2, when the basement depth is large, it is impossible to dig a place in time, you can use the reverse construction method, that is, dig a certain depth, then finished a section of retaining wall, to be a certain strength, and then open Dig, do the next retaining wall, and in this order until the construction to the specified design depth.

- Q: Roof membrane waterproof construction process, what should be noted that?

- Foundation treatment to find leveling to pay attention Five to: 1 slope accurate, smooth drainage 2 surface is flat 3 strong 4 clean 5 dry

- Q: Hello, roof with SBS waterproof material bulk density is how much?

- SBS Styrene-based thermoplastic elastomer is the largest yield (more than 70%) of SBCs, the lowest cost and wider application. It is a triblock copolymer with styrene and butadiene as monomer. Plastic and rubber properties, known as the "third generation of synthetic rubber".

- Q: Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Second, the chisel in addition to the wall structure to the wall structure for waterproof construction, you can use the material coating, membrane and infiltration of crystallization, the quality is different.

- Q: Roof leakage, what materials do the best waterproof

- The Second, if the roof is only the original did not do waterproof, only need to remove the leaky parts of 2 ~ 3cm deep after cleaning, you use asphalt irrigation, and now there is finished asphalt coating, such as sunny day when the treatment will basically not Leaked out. If there is a waterproof layer is too much trouble, to be around a range of waterproof tick, re-do waterproof, do when the attention and the original waterproof junction to do reinforcement layer. There are many ways to deal with leak detection, or to find some professional leak-proof companies to deal with this problem.

- Q: Roof for the insulation, Master roof, using two waterproof construction program

- Fourth, the finished product protection 1, has been laid the membrane waterproof layer, should be taken to protect the facilities, is strictly prohibited in the waterproof layer on the construction operations and transportation, and should be timely to do the protective layer of the waterproof layer. 2, through the roof, wall waterproof layer at the pipeline, construction and after the completion of damage shall not damage. 3, deformation joints, water, etc., before the construction of waterproof layer, should be temporary closure, waterproof layer is completed, should be cleared to ensure that the tube, sewn smooth, to meet the use of function. 4, roof construction shall not pollute the walls, cornices and other finished products.

- Q: What should you pay attention to before the construction of the basement waterproofing membrane?

- 3, painting the bottom line: for the reasonable arrangement of the daily pavement workload, must first on the basis of the program according to set the program to draw a good dividing line, the entire track and field into pieces, and then press the block by pavement. In order to ensure smooth drainage and less joints and other requirements, the use of the first outer ring after the construction process.

- Q: I would like to ask how to do in the warm water above,

- Do not know why you are in the floor to do the top of the waterproof? The We are here in the northeast of the winter is very cold, are warm, no one to warm the ground to do the above water, I think you over and over again, ah, no need, every family is warm, you have to do waterproof in the above is afraid of soaking your floor or tiles Bubble? The If the pipe really leaked, did not use the waterproof, the first warm tube must be selected, followed by your shop is good or bad, workers, water, are very important, you focus on this line on the line

- Q: Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- First, rigid (concrete) waterproof roofing SBS membrane should not be painted before the coating of any waterproof coating, otherwise it will damage the bonding strength of the coil and the grassroots.

- Q: What is the difference between finished mortar and cement mortar?

- Finished mortar and cement mortar difference: Cement mortar is the synthesis of three main materials, cement, sand and water, and mixed mortar is the synthesis of four major materials, cement, sand, lime and water.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 100 Million |

| Main Markets | America; Europe; Asia; the middle east |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 50% - 100% |

| No.of Employees in Trade Department | 6 - 10 people |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 20000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | |

Send your message to us

Asphalt Roofing Felt(ASTM STANDART)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 Square Meter m²

- Supply Capability:

- 300000 Square Meter per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords