Good Quality Breathable Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Breathable Membrane

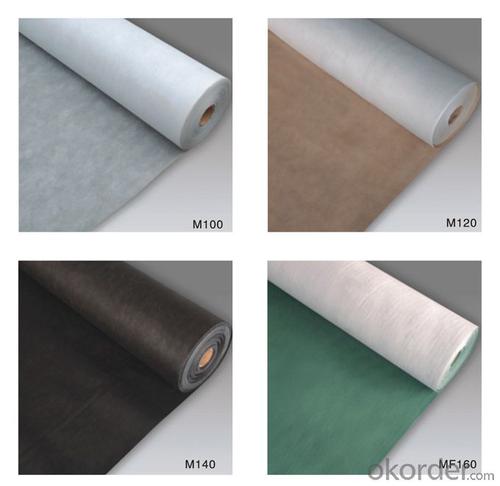

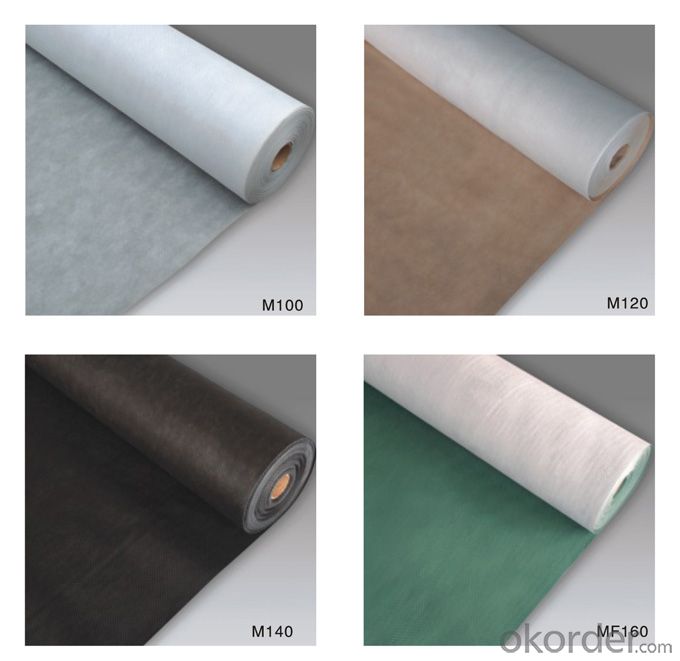

| Description of 3 layer breathable membrane: |

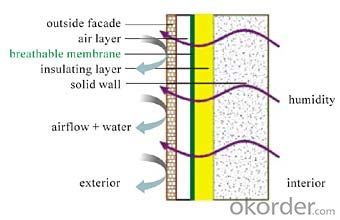

| Breathable membrane is thermal laminated by the high polymer material in the middle layer . Paving on the top of the insulation system, it can strengthen the water tightness of the building, as well as to eliminate humidity inside the containment by the unique breath ability, thus to retain the duration of building effectively , playing a part in thermal insulation, energy conservation and living environmental improvement.

|

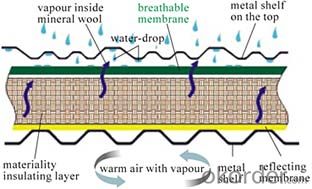

| Building up principle of 3 layer breathable roof membrane: |

| 3 layer breathable roof membrane, thermal laminated by high polymer material + polyolef in microporous membrane + high polymer material, we create this technology in China which is advanced all over the world. Polyolefin microporous membrane has excellent breathability, as well as good duration. Polyolefin microporous membrane has not only acid and alkali resistance, but also good extensibility which enable the fasresilience after tearing by nail so that to improve the sealing performance.

|

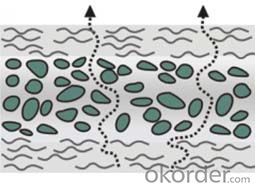

| Operating principle: |

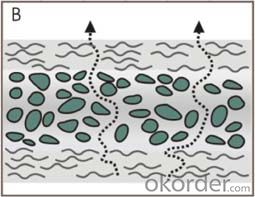

| There are two kinds of operation principle for breath: microspore and hydrophilic group. Breawarf breathable roof membrane adopt the principle of microspore. The minimum diameter of water drop is about 20 micron while the diameter of water vapour molecule is about 0.0004 micron, because of the enormous difference, water vapour can get across according to the dif fusibility, while water molecule can't pass because of the surface tension. As a result, the breathable membrane can prevent osmotic water , so that to have the water proof function.

|

| Characteristics of 3 layer breathable membrane: |

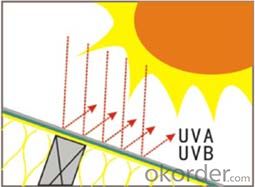

| A Excellent Performance at water resistance B Particular function of vapour permeability, so called breathable membrane C Good performance at UV resistance

D Tear resistance, wear resistance, good extensibility. |

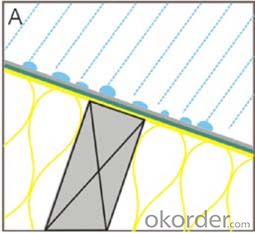

| Function of 3 layer breathable membrane: |

| Air-tightness of Breawarf breathable membrane Breawarf breathable membrane paves outside of the insulation system, wrap up the whole building, can strengthen air-tightness effectively and reduce air leak as well as convectional heat loss.

Permeability of Breawarf l3 ayer breathable membrane

Reduce construction cost |

| Application of breathable membrane |

| Mainly used as underlay for pitched roof and enclosure protection for insulating layer of walls. |

- Q: Bathroom first leveling or do waterproof, what is the difference

- 5. backfill rough flat mortar leveling, and its slope and do waterproof with the grassroots level and grass-roots waterproof, not tired. But pay special attention to this layer of closed water test (for most of the lack of toilet in the ground) is more important. 6. The surface layer and the adhesive layer, requires the slope has been done to slope or squatting, wall tiles to cover the tiles, reduce water into the wall.

- Q: Slope roof drains do not need to be waterproof

- When installing a waterproof board, when the width of a waterproof board is not enough, to be placed side by side, it should be noted that the gap between the board and the plate will provide potential space for root growth.

- Q: Eastern rainbow waterproof how to do

- Do not know where you use, waterproof as if a lot of materials. I know there are coiled, painted.

- Q: What decoration materials, light and water, and the wall, the perfect combination of glass

- Five, scraping gum The excess residue of the material to be scratched, scraping plastic tool angle consistent, at one go, scraping gum immediately after the completion of tearing tape or grain pattern paper. Remove the excess glass compound, if stains, can be removed with a damp cloth. Six, finished product protection Do not touch within 24 hours, do not press within 48 hours.

- Q: Roof membrane waterproof construction process, what should be noted that?

- Coil ply attention Paving direction, slope less than 3%, parallel and roof paving, slope greater than 15% or roof vibration, perpendicular to the roof paving. Slope between 3% to 15%, can be parallel to the vertical; membrane waterproof roof slope should not be greater than 25%. The upper and lower layers may not be piled on each other.

- Q: How does the finished ventilator manufacturer waterproof?

- do not play any silicone and tape, to avoid the silicone tape aging caused by leakage hazards. Can be done once and for all.

- Q: Hello, roof with SBS waterproof material bulk density is how much?

- As the SBS coil finished with pure asphalt is not the same, the coil includes a variety of surface material weight. The following is the different types and different thickness of the SBS coil unit area weight, due to the need to lap and pave the reinforcement layer, calculate the load in the following unit area weight, the general multiplied by 1.2 coefficient.

- Q: Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Second, the chisel in addition to the wall structure to the wall structure for waterproof construction, you can use the material coating, membrane and infiltration of crystallization, the quality is different.

- Q: Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- Second, the completion of the construction of the membrane and the acceptance of qualified, should do the protection of finished products, it is recommended to use cement mortar to do protective layer, construction should pay attention to the surface should be smooth pressure, and set the surface sub-grid, 1 m2. If the use of block material to do the protective layer, the sub-grid area should not be greater than 100 square meters, sub-grid width should not be less than 20mm; if the use of fine stone concrete protective layer, the sub-grid area should not be greater than 36 square meters. Note: Regardless of which protective layer is used, a separation layer should be provided between the waterproofing layer and the protective layer.

- Q: What are the materials used in the ceiling?

- Kitchen bathroom ceiling material is divided into four categories, namely, PVC material, aluminum gusset material, waterproof gypsum board, sauna board. Kitchen bathroom ceiling material 1: PVC material ????PVC is made of vinyl chloride in the role of the initiator made of thermoplastic resin, made of honeycomb shape. Suitable for use in damp places such as kitchen and toilet, because the PVC material ceiling in the life of a certain guarantee, you can use for 50 years without damage, while waterproof, heat insulation effect is good, but also has a certain noise Effect, in the kitchen is the best use of the ceiling material.

Send your message to us

Good Quality Breathable Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords