Breathable Membrane PP Non-woven Fabric Laminated with PE Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Breathable Membrane PP Non-woven Fabric Laminated with PE Film

General Information:

We are located in National Development Zone in Nantong, with 22000 square meters area, including 7000 square meters dust free workshop.

We have equipped the most advanced pp non-woven production line and composite production lines including extrusion lamination production, hot melt lamination production line, calendar bonded production line with the technology from Italy and Germany, printing production line, cutting production line. We specialize in producing waterproof and breathable materials and heat insulation materials, pp non-woven fabric, disposable medical products, packaging materials and so on.

Specifications:

Product Name | Composite PP Non-Woven Roofing Breathable Waterproof Membrane |

Color | Grey |

Structure | PP Non-Woven/PE Film/PP Non-Woven |

Roll Width(m) | 1.5m (+/-0.5%) |

Roll Length(m) | (1)50m,100m,200m,500m,1000m (2)according to the customers' requirements |

Basic Weight | 80g/m²,90g/m²,100g/m²,115g/m² ,120g/m² ,140g/m² ,160g/m² |

Temperature Resistance | -40 °C to 100 °C |

Water Resistant | Class 1 |

SD-Value | 0.02m |

Vapor Permeability | 2250g/m²/24h |

UV Resistant | 3-6 months |

Packing | 1)each roll packed by plastic bag, then with carton or pallets 2)according to the customers' request |

Price Terms | FOB,CNF,CIF |

Payment Terms | TT,LC, |

Delivery Time | within 15 working days after received your payment in advance |

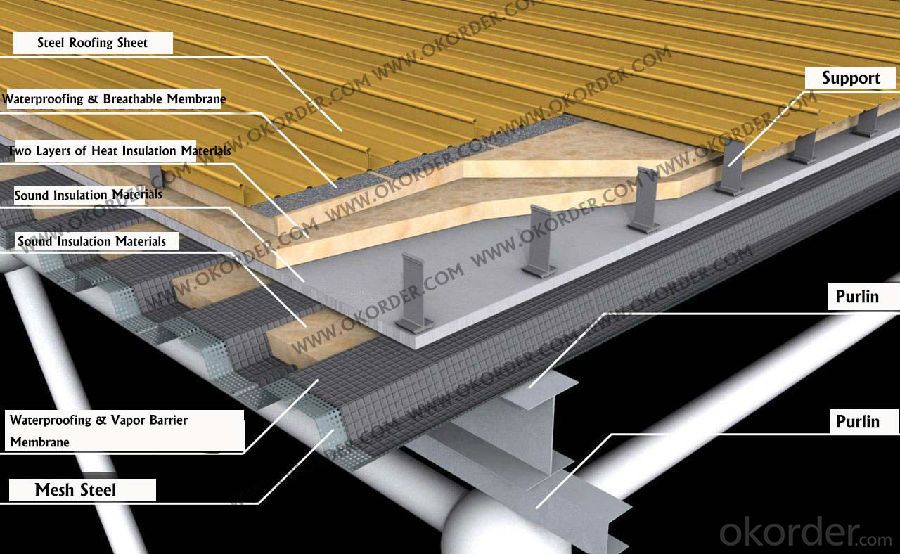

Typical Application:

Container Loading:

FAQ:

1. Where is your factory located in?

Our factory is located in Jiangsu province, close to Shanghai.

2. Have you ever been export?

Yes, our product has been exported to many countries.

3. Can we get samples?

Yes, we are free for samples, what you need to assume is freight charge.

- Q: Eastern rainbow waterproof how to do

- Do not know where you use, waterproof as if a lot of materials. I know there are coiled, painted.

- Q: Can acrylic materials be perforated? How to do waterproof after punching?

- Acrylic material thickness is generally below 2MM, Plus the total thickness of glass fiber reinforced plastic materials are generally below 4MM,

- Q: Roof membrane waterproof construction process, what should be noted that?

- Foundation treatment to find leveling to pay attention Five to: 1 slope accurate, smooth drainage 2 surface is flat 3 strong 4 clean 5 dry

- Q: What is the price of a waterproof window cover?

- 2, the bottom liner Composite sets of most of the finished use of the bottom liner and decorative panels. Market sales of the bottom liner and decorative panels are 1220 * 2440 mm specifications, the bottom liner thickness of 18,15,12 mm three, the production of doors and windows or cabinet liner thickness of the use of 18 mm. Bottom liner according to the different materials, is divided into blockboard, MDF, particleboard, melamine board. Commonly used for blockboard and MDF.

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- If you are out of the finished line, the best anti-static that can! I plant is the production of waterproof material, in addition to the internship when I went to the workshop, and now I do not go!

- Q: How does the finished ventilator manufacturer waterproof?

- In the latest country set JJCJ33 clearly stipulates that the structure to be waterproof, refers to the internal ventilation of all nodes and ventilators and roof all the nodes,

- Q: Hello, roof with SBS waterproof material bulk density is how much?

- SBS Styrene-based thermoplastic elastomer is the largest yield (more than 70%) of SBCs, the lowest cost and wider application. It is a triblock copolymer with styrene and butadiene as monomer. Plastic and rubber properties, known as the "third generation of synthetic rubber".

- Q: I would like to ask how to do in the warm water above,

- I do not do 80% of the warm water, of course, the use of good quality water pipes, waterproof water is generally done in the following to do, if done in the warm tube above will affect the heat of the floating, to warm the following covered with a Layer insulation layer and then covered with warm tube to, and then beat the water to ensure that no leakage. And finally in the above covered with wooden floor or floor tiles.

- Q: Villa roof leakage what general reasons, what materials to remedy

- Second, if the roof is only the original did not do waterproof, only need to remove the leaky parts of 2 ~ 3cm deep after cleaning, you use asphalt irrigation, and now there is finished asphalt coating, such as sunny day when the treatment will basically not Leaked out. If there is a waterproof layer is too much trouble, to be around a range of waterproof tick, re-do waterproof, do when the attention and the original waterproof junction to do reinforcement layer. There are many ways to deal with leak detection, or to find some professional leak-proof companies to deal with this problem.

- Q: What is the difference between finished mortar and cement mortar?

- Finished mortar for dry areas, because the addition of lime, lime water retention is good; cement mortar for wet areas, because the high strength.

Send your message to us

Breathable Membrane PP Non-woven Fabric Laminated with PE Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches