Vapor Resistance Film with PE and Fibergalss Reinforced

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vapor Resistance Film with PE and Fibergalss Reinforced

Introduction:

Vapor insulation membrane is a roof membrane with three-layers, which is specially designed for application on ventilated pitched roofing, can be used under bituminous membrane as a extra protection for the attic insulation. It includes PET/PP non-woven fabric layer, PE/PP woven layer and aluminum foil layer. The three-layers structure ensure extreme resistance to tearing. Furthermore, the special stabilization additives ensure 3-month resistance to UV radiation.

Specification:

Chemical Composition | PP & PE, Aluminum Foil, Woven Fabric |

Roll Size | 1.5meter*50meter |

Density: | 60gsm~130gsm |

Tensile Strength | MD:150N/50mm; CMD:115N/50mm |

Waterproofing Rate | W1 |

Vapor Resistant Rate | 6.9g/m2 ▪ 24h |

Aging rate under hot circumstance (90℃*168h) | MD:90%; CMD:100% |

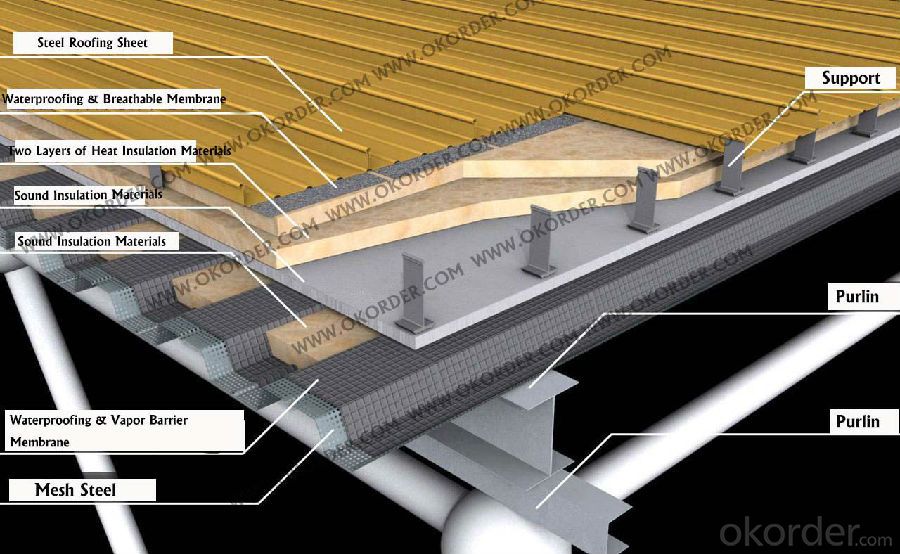

Typical Installation:

Typical Application:

Container Loading:

FAQ:

1. Where is your factory located in?

Our factory is located in Jiangsu province, close to Shanghai.

2. Have you ever been export?

Yes, our product has been exported to many countries.

3. Can we get samples?

Yes, we are free for samples, what you need to assume is freight charge.

- Q: Waterproof mortar expensive or dry mortar expensive

- Cationic neoprene latex is a polymer modified polymer anti-corrosion system. By the introduction of imported epoxy resin modified latex by adding the domestic neoprene emulsion and polyacrylate, synthetic rubber, various emulsifiers, modified latex and other components of the polymer latex.

- Q: What is the price of a waterproof window cover?

- 3, decorative panels Decorative panels are divided into paint-free panels and paint panels. Currently on the market, there are many window-free products, paint-free board is 5 mm density, the board pressure a layer of thin layer of color paper, due to the type of color paper, so there can be a lot of paint-free Color. Paint decorative panel is the surface of a layer of veneer plywood, there are many types, different wood has different colors. The benefits of window sets

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- If you are out of the finished line, the best anti-static that can! I plant is the production of waterproof material, in addition to the internship when I went to the workshop, and now I do not go!

- Q: Can Henkel have water against him?

- Add a small amount of water is possible because the premise of waterproofing should also be wet before the grassroots

- Q: FRP finished brush on what can be waterproof do not fade

- FRP appearance is the use of gel coat, we do the appearance of glass steel yacht are gel coat, also known as plastic shell, resin gel coat, etc., the color can be customized in the factory, Nanjing DSM company there.

- Q: What are the key points and contents of the quality control of waterproof material?

- 4, high-polymer modified asphalt waterproofing membrane: check the counterfeit effective and simple method is to cut the film wrapped down and then placed in the refrigerator freezer placed 3 hours after the removal, gently forced to break will be broken, and the national standard Require material low temperature flexibility to reach -20 ℃.

- Q: I would like to ask how to do in the warm water above,

- 1, I think the flexible mortar, waterproof paint better, because these materials in the construction process, not to warm the temperature caused too much impact, if the shop waterproofing membrane is too heavy, may affect the warm heat. 2, generally in the floor before the warmth, first do a waterproof, paved to warm to do once.

- Q: Developers have done waterproof, decoration house also have to do it

- Carbine water to remind you: the general finished house really done by the construction unit waterproofing, but we must know: First of all, developers for the rough housing waterproofing is more casual, may use the poor waterproof performance of the material, in the construction

- Q: Villa roof leakage what general reasons, what materials to remedy

- Third, for some of the city building cover the construction of red tiles leakage, as long as the removal of tiles on the grass, moss or dust after the replacement of tiles, leak-proof effect is the same. For flat roofs, the roof of the obvious cracks, with the tool will be cracked into a "V" or "U" shape, filling the caulking ointment, filled with cracks and above the use of waterproof wrap around the package.

- Q: Roof sunscreen waterproof layer leakage, brush milk white plastic can solve it?

- Second, check the plaster layer is empty, if not empty easy to use polyurethane brush twice, the surrounding multi-coated 10 cm. If the empty drum, then use the cutting machine to remove the plaster within the scope of the plaster, along the cracks on both sides of the expansion of 10 cm brush twice the polyurethane, brush the cement slurry and then do the surface layer. If a large area of ??leakage, it is recommended to use acrylic waterproof coating brush twice, because the polyurethane black too heat in summer affect the indoor temperature.

Send your message to us

Vapor Resistance Film with PE and Fibergalss Reinforced

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches