UAE Market Electric Galvanised Wire BWG 20 0.7mm Hot Dipped Galvnised Wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.UAE Market Electric Galvanised Wire BWG 20 0.7mm Hot Dipped Galvnised Wire Description:

Galvanized Iron Wire has the characteristics of thick zinc coating, good corrosion resistance, firm zinc coating, etc.

Galvanized Iron Wire mainly used in construction, express way fencing, binding of flowers and wire mesh weaving. Galvanized iron wire according to manufacturing technique, it includes hot-dipped galvanized iron wire and electro galvanized iron wire. Mainly telecommunication equipment and materials, medical equipment and device, weaving of wire mesh, steel rope, and filtration mesh, high-pressure pipe, construction, arts and crafts.

2.Main Features of UAE Market Electric Galvanised Wire BWG 20 0.7mm Hot Dipped Galvnised Wire :

• Use widely

• Corrosion- resistant

• Durable

• Practical use

• Beauty Surface

• Versatile

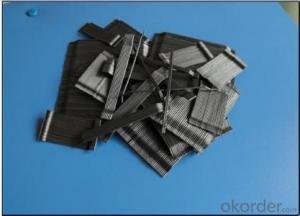

3. UAE Market Electric Galvanised Wire BWG 20 0.7mm Hot Dipped Galvnised Wire Images

4.UAE Market Electric Galvanised Wire BWG 20 0.7mm Hot Dipped Galvnised Wire Specification

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your products?

One of the most biggest manufacturer & supplier of wires and wire mesh,is a large-scale professional UAE Market Electric Galvanised Wire BWG 20 0.7mm Hot Dipped Galvnised Wire factory in China. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world. Different kinds of wires and mesh are available according to customer’s requirements.

②What is your Technical Information of Galvanized Wire?

1).Material: super carbon steel

2).Processing by drawing, hot-dip zinc-plating

3).Standard wire gauge from 8# to 24#

4).Thick zinc-coating layer

5).Super in corrosion resistance

6).Firm coating layer

7).Custom size available

③How long can we receive the product after payment?

In the purchase of Galvanized Iron Wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served。

- Q: 1994 crown vic but it seemed like only 3 or 4 wires matched up exactly and this one wire was way to short so i had to route it the best way i could the guy said it was the right set of wires but the car runs way better then it did just wondering should i change couple of wires around to make it fit or just leave it what does crossing the wires mean

- doad ya evehh hard a' punctuation? GETCHA SUMM

- Q: can a positive wire connect a negative and positive terminal together, or can a negative wire connect a positive and negative terminal together? This is regard to speakers in a guitar speaker cabinet. using rca speaker wire which is two wires that can be separated. One is positive and the other negative. If you are only using one half of the wire to wire two speakers in series does it matter if it is the positive(the side with the white stripe) or negative one since wiring in series is positive terminal to negative terminal.

- effective and detrimental keep on with to DC in elementary words, together with a battery or a skill grant. both of both might want to be grounded, or neither might want to be grounded. For AC, which varies between effective and detrimental voltages many circumstances per 2d, the words effective and detrimental are literally not used. instead, for an AC skill distribution device together with at your position of residing, you've a warm and impartial and a floor twine. The impartial is linked to floor at one element and is the go back for the warm, which has a voltage on it that varies between effective and detrimental voltages many circumstances per 2d. the floor twine is for safe practices. .

- Q: I bought a single pole dimmer switch to install in my dining room and when I took the old switch out nothing looked right. There are two wires which were joined together by another single wire which was attached to the top screw. There was another single wire (I believe the ground wire) attached to the bottom screw. I disconnected the first two wires and attached them separately to the black wires on the dimmer and attached the ground wires together. It didn't work. I've tired several different times with no luck. I put the wires back the way they were and attached them to the old switch and they no longer work ether. Help! How can I fix this problem? The old wires appear to be a very thick copper covered in black plastic and cloth.....

- Dimmer Switch Wiring

- Q: From my ceiling fan I have the following wires: green, white, blue and blackFrom my ceiling I have a bunch of wire in each of these colours: brown, red and orange.Which wires do I connect with each other??

- These are all probably hot-side wires. If you have the knowledge and the tools, find out which wire or wires is/are hot in the box with the switch off. If you have no idea what I am talking about, you REALLY need to find someone who knows electricity. BTW, the wires in the fan are quite simple to decode. The green wire is the ground and attaches to either the box or a ground wire in the box. The white wire is the neutral and attaches to the white wires in the box. The black is the hot lead for the fan and the blue is the hot lead for the light. These two can be combined if you have only one wall switch. Where they attach in the box will be determined by which hot lead is switched. I can probably guess how the box and switch are wired but I may be wrong and that would be dangerous. Call an electrician so you don't burn your house down.

- Q: I know what spark plugs are and where they are... but not sure what is meant by wires...For example checking/replacing spark plugs and wires to see if a problem is fixed..Are wires what hookup to the spark plugs from the (distributor?)

- The proper name for spark plug wires is: Ignition Wires. You're right, they are the leads that run from the distributor or ignition coil pack to the spark plugs. Some newer cars don't have ignition wires as such. A timed low voltage signal runs from small electrical wires directly to individual ignition coils which snap directly onto the spark plugs. Newer Toyota's are arranged like this.

- Q: Not the wire from RadioShack, but the really thin stuff used in modded circuit boards, logic circuits, low power circuits, etc.

- Use telephone cable,inside has more than 20 pieces of single wire. Or using ethernet cable,inside has 8 pieces of single wire.

- Q: Wire 1 and wire 2 are made from the same metal. Wire 2 has a larger diameter than wire 1. The electric field strengths E1 and E2 are equal. A) Compare the values of the two current densities. Is J1 greater than, less, or equal to J2?B) Compare the values of the currents I1 and I2. Is I1 greater then, less or equal to I2?

- The current will be more dense in the smaller wire. The value of the current is inversely proportional to the resistiance of the wire. Resistance = resistivity * length / Area since the wires are of identical material and length, the only thing left to vary is the cross-sectional area. Area is proportional to the square of the radius (diameter), so the current will be proportional to the square of the diameter. I2 is proportional to I1^2 I2 is larger than I1 .

- Q: is this a wire that like is the same as buying any other one?

- Wire is wire pretty much. Some manufactures will market thier wire as high strand or 99 percent oxygen free but you won't notice a difference. Its more for bragging rights.

- Q: Two steel wires are stretched with the same tension. The first wire has a diameter of 6.00E-4 m and the second wire has a diameter of 8.90E-4 m. If the speed of waves traveling along the first wire is 53.2 m/s, what is the speed of waves traveling along the second wire?

- Wave velocity v = √(T/μ) Same tension in both wires: T1 = T2 μ is the linear mass density v1 = 53.2 m/s v2 = ? = v1/v2 = √(T1/μ1) / √(T2/μ2) = √(T1μ2 / T2μ1) = √(T1/T2 * μ2/μ1) = √(μ2/μ1) Linear mass density is mass/length, mass is density*volume: m/L = ρV/L = ρAL/L = ρA = ρπr^2 Both wires are steel so their density is the same. == v1/v2 = √(μ2/μ1) = √(ρπr2^2 / ρπr1^2) = √(r2^2 / r1^2) = r2/r1 == v2 = v1r1/r2 = (53.2*3.00×10^-4) / 4.45×10^-4 = 35.9 m/s ---- Speed of waves along the second wire is 35.9 m/s

- Q: I'm trying to install an aftermarket radio in my 2005 suzuki forenza, but it isn't working. The display on the radio doesn't even light up. I'm thinking that it is because there are some unused wires on the oem harness. There is no plug on the original harness thanks to a previous owner, so an adapter plug is out of the question, so i just need to know what wires should or should not be connected to what other wires. The ones which have no equivalent on the aftermarket radio are: illumination wire, and dimmer wire. If someone could provide some info, that would be awesome. The radio being installed is a sony cdx-gt57up.

- Suzuki Wiring Harness

Send your message to us

UAE Market Electric Galvanised Wire BWG 20 0.7mm Hot Dipped Galvnised Wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords