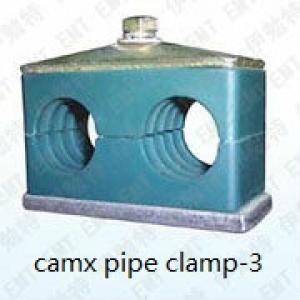

U shape pipe clamp for SANY Concrete Pump with high quanlity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete pump pipe clamp is applicable to concrete pump pipe.Its belongs to concrete pump spare parts

U shape pipe clamp for SANY Concrete Pump with high quanlity

Specifications

stainless steel u bolt clamp steel pipe

1.Manufactur supply directly.

2.Size:M4-M48.etc

3.ISO,SGS.

4.Grade:201,304,316...

stainless steel u bolt clamp steel pipe

Size:stainless steel u-bolts

M6x16-50

M8x20-100

M10x20-100

M12x20-100

M14x30-100

M16x30-100

M18x40-100

M20x40-100

M22x50-100

M27x50-100

M30x50-100

M36x50-100

material:stainless steel

201

304 0Cr18Ni9 304L 00Cr19Ni10

321 0Cr18Ni9Ti 316 0Cr17Ni12Mo2

316L 00Cr17Ni14Mo2 310S 0Cr25Ni20

surface:bright

Tolerance: +/-0.015mm

Grade: 4.6 4.8 5.6 5.8 6.8,etc

DN125 Concrete Pump Clamp Coupling

Type-HD

| 1.5" clamp HD |

2" clamp HD |

| 3" clamp HD |

| 4" clamp HD |

| 3"clamp HD (adjustable) |

| 4"clamp HD (adjustable) |

| 2.5" clamp HD |

| 5" clamp HD |

| 5" clamp HD (adjustable) |

Type-Bolt& snap

Bolt Clamp 2" |

| Bolt Clamp 3" |

| Bolt Clamp 4" |

| Bolt Clamp 5" |

| Bolt Clamp 6" |

| Bolt Clamp Boom Bracket Type 5" |

| Two Bolts Boom Clamp 5" |

| Snap Clamp 2" |

| Snap Clamp 3" |

| Snap Clamp 4" |

| Snap Clamp 4.5" |

| Snap Clamp 5" |

| Snap Clamp 6" |

- Q: What are the indications of a faulty control lever?

- There are several indications that can suggest a faulty control lever. First and foremost, if the control lever is not responding or is sluggish when you try to engage or disengage a specific function, it could be a sign of a problem. This could include difficulty shifting gears, adjusting speed, or operating various controls such as the throttle or clutch. Another indication of a faulty control lever is if it becomes loose or wobbly. If you notice excessive play or movement in the lever, it could indicate that the mechanism connecting the lever to the control system is worn out or damaged. This can compromise the accuracy and precision of the control lever, making it difficult to operate the intended functions effectively. Additionally, unusual noises or vibrations coming from the control lever can be a sign of a fault. This could be a result of loose or broken components within the control lever assembly, indicating that it needs to be inspected and repaired. Lastly, if the control lever becomes stuck or jammed in a certain position, it is a clear sign of a faulty lever. This can prevent you from properly controlling the equipment or vehicle, posing safety risks. In any case, if you suspect a faulty control lever, it is essential to have it inspected and repaired by a qualified technician to ensure proper functioning and safe operation.

- Q: How can a faulty boom affect the concrete placement process?

- A faulty boom can have significant implications on the concrete placement process. Firstly, it can compromise the safety of the workers involved. A faulty boom may not be able to support the weight and pressure exerted by the concrete, leading to potential collapse or failure, endangering the lives of the workers present at the site. Secondly, a faulty boom can result in inaccurate and uneven concrete placement. The boom's malfunctioning parts may cause the concrete to be discharged at incorrect angles or distances, leading to uneven distribution and an inconsistent concrete surface. This can affect the structural integrity and aesthetics of the final product. Additionally, a faulty boom can lead to delays and disruptions in the concrete placement process. If the boom breaks down or malfunctions during the operation, it will require repairs or replacement, causing downtime and potentially halting the construction work. This can result in project delays, increased costs, and overall inefficiency. Lastly, a faulty boom can result in wastage of concrete. If the boom is not functioning properly, it may not be able to control the flow and discharge of the concrete accurately. This can lead to spills, overflows, or excessive pouring, resulting in unnecessary wastage of concrete material. This not only increases project costs but also has environmental implications. Overall, a faulty boom can have severe consequences on the safety, accuracy, efficiency, and cost-effectiveness of the concrete placement process. It is crucial to ensure that booms are regularly inspected, properly maintained, and promptly repaired to mitigate any potential risks and ensure smooth concrete placement operations.

- Q: What are the functions of concrete pump truck?

- It is composed of pump body and conveying pipe. It is divided into piston type, extrusion type and water pressure diaphragm type according to the structure. The pump body is mounted on the automobile chassis, and then equipped with telescopic or bent cloth rods to form a pump truck

- Q: What are the causes of pipe blockage in concrete pump?

- When the fine sand content through the 0.315mm screen is small, even if other concrete technical specifications meet the requirements, it will plug the pipe. Because these fine sand plays a similar role in the concrete, it can reduce the friction between the tube wall and concrete, improve the fluidity, increase the cohesion and water retention, and greatly affect the concrete pumping performance

- Q: Can concrete pump spare parts be retrofitted to older pump models?

- Yes, concrete pump spare parts can often be retrofitted to older pump models. Many manufacturers design their spare parts to be compatible with multiple pump models, including older ones. However, it is important to note that not all spare parts may be suitable for retrofitting, as compatibility can vary depending on the specific pump model and the part in question. It is advisable to consult with the manufacturer or a qualified technician to ensure that the spare parts are compatible and can be safely retrofitted to older pump models.

- Q: How do I maintain the performance of concrete pump spare parts in extreme weather conditions?

- To maintain the performance of concrete pump spare parts in extreme weather conditions, it is crucial to take certain precautions. Firstly, ensure that the spare parts are properly protected from direct exposure to harsh weather elements such as rain, snow, or extreme heat. This can be achieved by using covers or shelters to shield the parts. Additionally, regular cleaning and lubrication of the spare parts will help to prevent any buildup of dust, dirt, or moisture that could potentially affect their performance. Lastly, conducting regular inspections and maintenance checks will allow for early detection of any damage or wear, enabling timely repairs or replacements to be made, thus ensuring optimal performance in extreme weather conditions.

- Q: How can I determine if the concrete pump cylinder needs replacement?

- In order to determine whether the concrete pump cylinder needs replacement, several inspections and tests can be conducted. 1. Perform a visual inspection and look for any visible signs of wear and tear on the cylinder, such as cracks, dents, or corrosion. Additionally, check for leaks or excessive hydraulic fluid around the cylinder. 2. Evaluate the pump's performance during operation. Pay attention to any decrease in pumping efficiency, irregular flow, or decreased pressure, as these could indicate a problem with the cylinder. 3. Conduct a pressure test to assess the cylinder's ability to handle the required pressure. This can be done by isolating the cylinder and pressurizing it to a level higher than its typical operating pressure. If the cylinder fails to maintain pressure or shows signs of leakage, replacement may be necessary. 4. Measure the stroke length of the cylinder during operation. Uneven stroke lengths may indicate internal damage and could require replacement. 5. If you are uncertain about the cylinder's condition, seek consultation with professionals or experts in the field. They can provide a more accurate assessment and recommend the appropriate course of action, which may include cylinder replacement. Remember that regular maintenance and inspections are essential for the concrete pump's longevity and efficient operation. Addressing potential issues early on can help prevent further damage or accidents.

- Q: How can a malfunctioning control lever affect the pump's operation?

- A malfunctioning control lever can significantly impact the pump's operation in several ways. Firstly, the control lever is responsible for regulating the flow rate and pressure of the pump. If the lever is malfunctioning, it may not be able to accurately adjust these parameters, leading to improper functioning of the pump. Secondly, a malfunctioning control lever may not be able to switch the pump on or off effectively. This can result in the pump continuously running, even when it is not required, leading to unnecessary wear and tear on the pump and increased energy consumption. Additionally, the control lever is often used to control the direction of flow in the pump. If it is malfunctioning, it may not be able to switch the pump between forward and reverse modes, affecting the pump's ability to perform its intended tasks efficiently. Furthermore, a malfunctioning control lever can impact the overall safety of the pump operation. If the lever fails to respond or gets stuck in a position, it can potentially lead to over-pressurization, leaks, or other hazardous situations, putting both the pump and surrounding equipment or personnel at risk. In summary, a malfunctioning control lever can disrupt the pump's ability to accurately regulate flow rate, pressure, and direction of flow, potentially leading to improper functioning, increased energy consumption, reduced efficiency, and safety hazards. Therefore, it is crucial to promptly address any issues with the control lever to ensure the reliable operation of the pump.

- Q: How do concrete pump spare parts contribute to the overall performance of the pump?

- Enhancing the overall performance of the pump, concrete pump spare parts play a crucial role. These spare parts are specifically designed to endure the harsh and demanding conditions of pumping concrete, guaranteeing the efficiency and longevity of the pump. An important factor in the pump's overall performance is the ability of concrete pump spare parts to enhance pumping capacity and efficiency. These spare parts, including pump cylinders, pistons, and valves, are designed to ensure a consistent and smooth flow of concrete without any interruptions. By maintaining a steady flow, these spare parts maximize the pump's capacity, enabling it to handle larger volumes of concrete in less time. Furthermore, concrete pump spare parts contribute to the pump's performance by improving its durability and reliability. These spare parts are made from high-quality materials like hardened steel and wear-resistant alloys, specifically chosen to withstand the abrasive nature of concrete. This ensures that the pump can operate continuously without experiencing premature wear or failure. Concrete pump spare parts also ensure the safety of the pump operators and the environment. For instance, wear plates and cutting rings prevent concrete leakage, reducing the risk of accidents and environmental contamination. Similarly, seals and gaskets provide a secure and tight connection between different components, preventing leaks or malfunctions. Moreover, concrete pump spare parts reduce downtime and maintenance costs. As these spare parts undergo wear and tear during operation, they are designed to be easily replaceable. This allows for quick and efficient repair or replacement of damaged parts, minimizing the pump's downtime. Additionally, using genuine and high-quality spare parts reduces the need for frequent repairs and maintenance, resulting in lower overall maintenance costs. In conclusion, concrete pump spare parts are vital components that significantly contribute to the pump's overall performance. They enhance its pumping capacity, durability, and reliability, ensuring a smooth and efficient operation. Furthermore, these spare parts promote safety, reduce downtime, and minimize maintenance costs, making them indispensable for the optimal performance of concrete pumps.

- Q: Are there any warranties or guarantees on concrete pump spare parts?

- Yes, there are warranties and guarantees available on concrete pump spare parts. Many reputable manufacturers and suppliers offer warranties to ensure the quality and performance of their products. These warranties typically cover defects in materials or workmanship and provide replacements or repairs within a specified time frame. It is important to check the terms and conditions of the warranty or guarantee provided by the specific supplier or manufacturer before purchasing concrete pump spare parts.

Send your message to us

U shape pipe clamp for SANY Concrete Pump with high quanlity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords