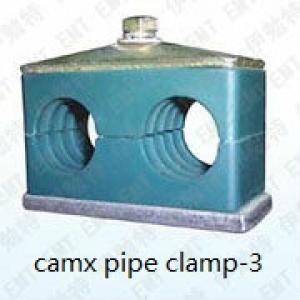

Sany Concrete Pump Clamp High Pressure Forge

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

A coupling is a device used to connect two delivery pieps together at their ends for the purpose of transmitting, and prevent the concrete from leaking. Couplings do not normally allow disconnection of shafts during operation.

Main Product Features:

1. use high quality steel.After high-temperature 1200 forging,it’s shaped.

2.High temperature forging.

3.convenient to use, easy operation,and high safety.

4.good sealing,wear-resising,longer service life.

5.do not restrict the steering tubes, pipes during the working process can be 360 degrees rotation.

6.used in concrete pump truck,concrete pump and pipeline connection seal in construction

work equipment.

Product Specifications:

1.Forged

2.2--8 inch

3.Galvanizing/Baking varnish

4.More durable,light,beautiful

Production steps:

Concrete pump clamp Catalogue:

FAQ:

1.How do you regarding your product quality?

As our principle is more safety to save more. In China, there are lots of manufactures of this line, but we are the first one that use the forging technic in producing, firmly meet the PM standard.

2.Can I get some samples?

Of course you can. Small sample for free, but you pay the express. For some products are not small, like concrete pump pipe, it’s very difficult to deliver one pipe of 3000mm. If it’s possible, we’d like that you can come here to visit our factory. Welcome!

3. I want to make our logo on the products, is that ok?

Yes, it’s totally ok. OME is available from us.What you should do is send your logo, brand name, or picture to us. And let other things leave on us.

- Q: How can one identify the correct type of rubber seals or gaskets for concrete pump spare parts?

- In order to determine the appropriate rubber seals or gaskets for concrete pump spare parts, there are several steps that can be followed: 1. Refer to the manufacturer's documentation: Review the concrete pump's manual or any accompanying documentation provided by the manufacturer. This information typically includes details about the required type and size of rubber seals or gaskets for different components of the pump. 2. Take accurate measurements: Precisely measure the dimensions of the seals or gaskets that need to be replaced. This includes determining the inner diameter, outer diameter, and thickness. These measurements will assist in finding the correct size of seals or gaskets. 3. Consider material compatibility: Take into account the compatibility of the rubber seals or gaskets with the concrete being pumped. Certain types of rubber can be degraded by chemicals or additives present in the concrete. It is important to select seals or gaskets made of a material that is resistant to the specific chemicals found in the concrete. 4. Seek advice from experts: If uncertain about the specific type of rubber seal or gasket required for the concrete pump, it is recommended to seek guidance from experts. Contact the manufacturer directly or consult a reputable supplier or distributor specializing in concrete pump spare parts. They can provide expert advice and recommend the appropriate seals or gaskets based on the specific model and requirements of the pump. Remember to prioritize the use of the correct type of rubber seals or gaskets to maintain the efficiency and safety of the concrete pump. Taking the time to identify the right parts will ensure optimal performance and reduce the risk of premature wear or failure.

- Q: Can I get spare parts for both concrete pumps with and without remote control systems?

- It is indeed feasible to obtain spare parts for both concrete pumps that come with or without remote control systems. Numerous construction equipment manufacturers and suppliers provide spare parts for a wide range of concrete pump models and types. Regardless of whether your pump is equipped with a remote control system or not, reliable suppliers typically offer replacement parts like valves, cylinders, hoses, pistons, and other components. When ordering spare parts, it is crucial to provide accurate specifications and model information to ensure compatibility with your specific concrete pump.

- Q: What is the role of a concrete pump seal?

- The role of a concrete pump seal is to prevent leakage and maintain the pressure within the pumping system. Concrete pumps are used to transfer liquid concrete from one location to another, typically from a mixer truck to a construction site. These pumps operate under high pressure to ensure the concrete flows smoothly through the pipeline. A concrete pump seal is a vital component that helps maintain the integrity of the pumping system. It is usually made of durable materials such as rubber or polyurethane, designed to withstand the high pressures and abrasive nature of concrete. The seal is located at the connection points between various sections of the pipeline, including the pump, pipeline joints, and hose connections. The primary function of the seal is to prevent concrete from leaking out of the system. Concrete is a viscous material, and any leakage can cause significant problems, such as a decrease in pumping efficiency, wastage of concrete, and potential damage to the surrounding environment. The seal ensures that the pumping system remains leak-free, allowing for efficient and continuous concrete transfer. Additionally, the seal helps maintain the required pressure within the pumping system. Concrete pumps rely on consistent pressure to ensure the concrete is delivered smoothly and evenly. Any pressure loss due to leakage can lead to uneven flow or blockages in the pipeline, affecting the overall performance of the pump. By sealing the connection points, the seal helps maintain the desired pressure, ensuring the concrete is pumped efficiently. Overall, the role of a concrete pump seal is to prevent leakage, maintain pressure, and ensure the smooth and efficient transfer of concrete from the source to the destination. It is an essential component that contributes to the overall effectiveness and reliability of concrete pumping operations.

- Q: What are the signs of a damaged concrete pump cylinder?

- There are several signs that can indicate a damaged concrete pump cylinder. One of the most obvious signs is leakage of hydraulic fluid from the cylinder. If you notice any fluid dripping or pooling around the cylinder, it could be an indication of a damaged seal or piston. Another sign of a damaged concrete pump cylinder is abnormal noise during operation. If you hear any unusual clanking, grinding, or knocking sounds coming from the pump, it could be a result of a damaged cylinder. This can be caused by a variety of issues such as a bent piston rod, worn out bearings, or misalignment of components. Decreased pumping efficiency is also a common sign of a damaged cylinder. If you notice that the pump is not delivering concrete as effectively as it used to, it could be due to a damaged cylinder. This can result in reduced output, slower pumping speed, or even complete failure to pump concrete. Visual inspection can also help identify signs of a damaged cylinder. Look for any visible cracks, dents, or deformations on the cylinder body. Additionally, check for any signs of excessive wear on the piston or piston rod, such as scratches or grooves. Lastly, if you experience frequent breakdowns or malfunctions with the concrete pump, it could be an indication of a damaged cylinder. Constant repairs or failures can be a result of underlying issues with the cylinder, such as fatigue, corrosion, or improper maintenance. If you notice any of these signs, it is important to address the issue promptly. Continuing to operate a concrete pump with a damaged cylinder can lead to further damage, increased repair costs, and potential safety hazards. It is recommended to consult a professional technician or manufacturer to assess and repair the damaged cylinder.

- Q: How often should concrete pump seals be replaced?

- The replacement of concrete pump seals depends on various factors, such as the type of pump, seal quality, operating conditions, and maintenance practices. It is generally recommended to inspect and replace the seals every 500 to 1,000 pumping hours or annually, whichever comes first. It is crucial to regularly inspect the seals to detect any signs of wear or damage. Common indications for replacement include leaks, excessive vibration, reduced pumping efficiency, or visible degradation of the seal material. If any of these issues are observed, it is important to promptly replace the seals to prevent further damage and ensure optimal pump functioning. It is important to note that certain pumps may require more frequent seal replacements due to their design or operating conditions. For example, high-pressure pumps or those used in abrasive environments may experience accelerated seal wear, necessitating more frequent replacements. To extend the lifespan of concrete pump seals, proper maintenance and care are essential. This involves regularly cleaning the pump and seals, ensuring proper lubrication, and following the manufacturer's guidelines for operation and maintenance. Additionally, using high-quality seals and regularly inspecting them for wear can help prolong their longevity. Ultimately, determining the replacement frequency of concrete pump seals involves a combination of regular inspections, adherence to maintenance practices, and consideration of specific operating conditions.

- Q: What is the function of a concrete pump control valve?

- The function of a concrete pump control valve is to regulate the flow of concrete from the pump to the desired location. It allows the operator to control the speed and direction of the concrete flow, ensuring the precise placement of the concrete. The control valve also helps in preventing any blockages or clogs in the pumping system by allowing the operator to adjust the pressure and flow rate of the concrete. Additionally, the control valve helps in maintaining the safety of the operation by providing the operator with the ability to stop or start the concrete flow as needed. Overall, the concrete pump control valve plays a crucial role in efficiently and effectively transferring concrete from the pump to the desired location.

- Q: What are the safety measures to consider while replacing concrete pump spare parts?

- When replacing concrete pump spare parts, there are several safety measures that should be considered to ensure the safety of the workers and the overall success of the replacement process. 1. Lockout/Tagout: Before starting any maintenance or replacement work, it is crucial to follow proper lockout/tagout procedures. This involves isolating the equipment from its power source and placing lockout devices to prevent accidental startup. This ensures that the equipment cannot be operated while replacement work is being carried out. 2. Personal Protective Equipment (PPE): Workers involved in the replacement process should wear appropriate PPE such as safety goggles, gloves, hard hats, and steel-toed boots. This protects them from potential hazards like flying debris, falling objects, or accidental contact with sharp edges. 3. Equipment Inspection: Before commencing the replacement, the equipment should be thoroughly inspected to identify any potential hazards or defects. This includes checking for damaged or worn-out parts, loose connections, or any signs of deterioration. If any issues are found, they should be resolved or repaired before proceeding with the replacement. 4. Proper Lifting Techniques: Concrete pump spare parts can be heavy and bulky, so it is essential to use proper lifting techniques to prevent musculoskeletal injuries. Workers should be trained on lifting techniques and should use mechanical aids like cranes, hoists, or forklifts when necessary. Additionally, team lifting should be employed when dealing with heavy or awkwardly shaped parts. 5. Secure Work Area: The work area should be properly secured to prevent unauthorized access and ensure the safety of workers. Barricades or caution tape can be used to cordon off the area and warn others of the ongoing replacement work. Adequate lighting should also be provided to ensure clear visibility. 6. Proper Tools and Equipment: Using the right tools and equipment is crucial for safe and efficient replacement work. Workers should be trained on the proper use of tools and ensure that they are in good working condition. Using damaged or faulty tools can lead to accidents or improper installation of the spare parts. 7. Follow Manufacturer's Instructions: It is important to follow the manufacturer's instructions and guidelines for replacing concrete pump spare parts. This includes understanding the correct sequence of steps, torque requirements, and any special precautions that need to be taken. Deviating from the manufacturer's instructions can compromise the safety and performance of the equipment. By following these safety measures, the risk of accidents, injuries, or equipment damage can be minimized during the replacement of concrete pump spare parts. It is crucial to prioritize safety at all times and ensure that all workers involved are properly trained and equipped to carry out the replacement work.

- Q: How often should concrete pump clamps be inspected and replaced?

- Concrete pump clamps should be inspected on a regular basis to ensure they are functioning properly and to identify any signs of wear or damage. The frequency of inspections will depend on various factors such as the frequency of use, the type of concrete being pumped, and the working conditions. In general, it is recommended to inspect concrete pump clamps at least once a month or after every 100 hours of operation, whichever comes first. This will help catch any potential issues early on and prevent them from escalating into major problems. Additionally, it is important to visually inspect the clamps before each use to check for any visible signs of damage or wear. This includes checking for cracks, deformations, or any loose or missing bolts. The lifespan of concrete pump clamps will vary depending on the quality of the clamps, the intensity of use, and the maintenance practices. However, as a general guideline, it is recommended to replace the clamps every 1-2 years or sooner if they show significant signs of wear or damage. Regular inspections and timely replacements of concrete pump clamps are vital to ensure the safety and efficiency of the pumping operations. It is always better to be proactive and address any potential issues promptly to prevent costly repairs or accidents.

- Q: Can I get spare parts for both piston and rotary concrete pumps?

- Yes, you can get spare parts for both piston and rotary concrete pumps. Many manufacturers and suppliers offer a wide range of spare parts for these types of pumps. These parts include but are not limited to pistons, seals, valves, wear plates, hydraulic components, and bearings. It is important to ensure that you purchase genuine spare parts from reputable suppliers to ensure the quality and compatibility with your specific pump model. Additionally, it is recommended to have a regular maintenance and inspection schedule for your concrete pump to identify any worn-out parts and replace them promptly to avoid any potential breakdowns or disruptions in your construction projects.

- Q: Can concrete pump spare parts be tested for compatibility with different types of concrete mixes?

- Yes, concrete pump spare parts can be tested for compatibility with different types of concrete mixes. These tests typically involve evaluating the performance, durability, and efficiency of the spare parts when used with various concrete compositions. This ensures that the spare parts can handle the specific requirements and characteristics of different concrete mixes effectively.

Send your message to us

Sany Concrete Pump Clamp High Pressure Forge

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords