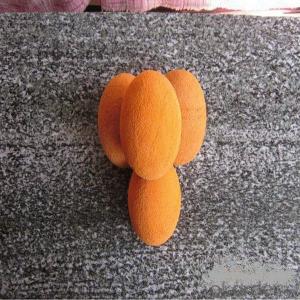

Concrete Pump Sponge Ball DN150 with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CONCRETE PUMP CLEANING SPONGE BALL

- SIZE:DN125/ 6"

- SOFT, MEDIUM SOFT, HARD

- GENERAL USE FOR CONCRETE MIXER & PUMP

- MATERIAL: RUBBER

- PLACE OF ORIGIN: CHINA

Product Description:

Product Name: CONCRETE PUMP CLEANING SPONGE BALL

1. Specification

Concrete Pump Cleaning Sponge Ball

- SIZE:DN150/ 6"

- SOFT, MEDIUM SOFT, HARD

- GENERAL USE FOR CONCRETE MIXER & PUMP

- MATERIAL: RUBBER

- PLACE OF ORIGIN: CHINA

Name | Material | Size | Function |

Clean Ball | Sponge Rubber | DN 80(3inch) | Clean pump pipe |

Clean Ball | Sponge Rubber | DN 100(4inch) | Clean pump pipe |

Clean Ball | Sponge Rubber | DN 125(5inch) | Clean pump pipe |

Clean Ball | Sponge Rubber | DN 150(6inch) | Clean pump pipe |

Clean Ball | Sponge Rubber | DN 200(8inch) | Clean pump pipe |

2. Application

1.Applacation:cleaning the pipeline of the concrete pump

2.Suitable for the various :Schwing CIFA PMZoomlion SANY and so on.

3. Package

Put into containers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce Concrete Pump Sponge Ball DN150 according to customers request?

A4: Yes, we can produce Concrete Pump Sponge Ball DN150 according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: We have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Image:

- Q: How does a concrete pump agitator motor prevent concrete from settling?

- A concrete pump agitator motor prevents concrete from settling by constantly agitating the mixture. The motor is typically equipped with paddles or blades that rotate inside the mixing drum, ensuring that the concrete remains in a homogeneous state. When concrete is being transported, it tends to separate due to gravity and the natural settling of heavier aggregates. This can result in a non-uniform consistency, with denser materials sinking to the bottom and water rising to the top. The agitator motor counteracts this settling process by continuously stirring the concrete. The rotating paddles or blades create a turbulent flow within the mixing drum, preventing the heavier aggregates from settling and maintaining a consistent mixture. This agitation helps to evenly distribute the cement, aggregates, water, and any additional additives throughout the concrete, resulting in a more uniform and reliable end product. By preventing the settling of concrete, the agitator motor ensures that the mixture is consistently workable and can be pumped or poured without any blockages or inconsistencies. This is especially crucial during construction projects where precise and consistent concrete placement is required. In summary, a concrete pump agitator motor prevents settling by agitating the mixture, keeping it homogeneous and ensuring a consistent flow during pumping or pouring operations.

- Q: What are the indications of a faulty control lever?

- There are several indications that can suggest a faulty control lever. First and foremost, if the control lever is not responding or is sluggish when you try to engage or disengage a specific function, it could be a sign of a problem. This could include difficulty shifting gears, adjusting speed, or operating various controls such as the throttle or clutch. Another indication of a faulty control lever is if it becomes loose or wobbly. If you notice excessive play or movement in the lever, it could indicate that the mechanism connecting the lever to the control system is worn out or damaged. This can compromise the accuracy and precision of the control lever, making it difficult to operate the intended functions effectively. Additionally, unusual noises or vibrations coming from the control lever can be a sign of a fault. This could be a result of loose or broken components within the control lever assembly, indicating that it needs to be inspected and repaired. Lastly, if the control lever becomes stuck or jammed in a certain position, it is a clear sign of a faulty lever. This can prevent you from properly controlling the equipment or vehicle, posing safety risks. In any case, if you suspect a faulty control lever, it is essential to have it inspected and repaired by a qualified technician to ensure proper functioning and safe operation.

- Q: Can I get spare parts for both concrete pumps with and without remote control systems?

- Yes, spare parts are available for both concrete pumps with and without remote control systems.

- Q: What is the role of a concrete pump seal?

- The role of a concrete pump seal is to prevent leakage of concrete or other fluids from the pump system, ensuring that the pump operates efficiently and effectively.

- Q: How often should concrete pump remote controls be inspected and maintained?

- Concrete pump remote controls should be inspected and maintained on a regular basis to ensure their proper functioning and to prevent any potential issues. The frequency of inspections and maintenance will depend on various factors such as the intensity of use, environmental conditions, and the specific recommendations provided by the manufacturer. As a general guideline, it is recommended to inspect and maintain concrete pump remote controls at least once every three months. This includes checking for any visible damage, loose or worn-out parts, and ensuring that all buttons and switches are working properly. Additionally, it is important to inspect and clean the battery compartment, and replace batteries if necessary. However, in high-demand situations or extreme environmental conditions, more frequent inspections and maintenance may be required. For instance, if the concrete pump is used in a harsh environment with excessive dust or moisture, it may be necessary to increase the frequency of inspections and cleanings to prevent any potential damage or malfunction. It is also crucial to follow the manufacturer's guidelines and recommendations for maintenance. They may provide specific instructions on lubrication, calibration, or other maintenance procedures that should be performed at regular intervals. By adhering to these guidelines, concrete pump remote controls can be kept in optimal condition, ensuring safe and efficient operation.

- Q: What are the signs of a faulty concrete pump control box?

- There are several signs that may indicate a faulty concrete pump control box. These signs can vary depending on the specific issue, but some common signs include: 1. Unresponsive controls: One of the most obvious signs of a faulty control box is when the controls become unresponsive or fail to function properly. This may include buttons that do not work, switches that do not engage, or a lack of response when adjusting settings. 2. Inaccurate readings: Another sign of a faulty control box is when the readings or measurements displayed on the control panel are inaccurate or inconsistent. This may include incorrect pressure readings, flow rates, or other important measurements necessary for proper pump operation. 3. Electrical issues: Faulty control boxes can also cause electrical problems such as flickering lights, sudden power surges or shortages, or even blown fuses. These electrical issues can be dangerous and may lead to further damage if not addressed promptly. 4. Strange noises: When a control box is faulty, it may produce strange noises, such as buzzing, humming, or clicking sounds. These noises can indicate loose connections, damaged components, or malfunctioning parts within the control box. 5. Pump malfunctions: A faulty control box can also cause the concrete pump itself to malfunction. This may include issues such as inconsistent pumping, irregular flow, or sudden stops and starts. These problems can disrupt the concrete pouring process and potentially lead to project delays. If you suspect a faulty concrete pump control box, it is crucial to address the issue promptly. It is recommended to consult a qualified technician or contact the manufacturer for assistance in diagnosing and repairing the control box.

- Q: How does the concrete pump work?

- After position, the pump shall show stop light to avoid collision

- Q: What are the signs of a damaged or malfunctioning electric motor?

- A damaged or malfunctioning electric motor can be identified by several signs. Firstly, unusual noises like grinding, squealing, or banging sounds are typically indicative of a problem. Such sounds may suggest that the motor's bearings are worn out or that there is an issue with its internal components. Secondly, excessive heat is another sign of a damaged electric motor. If the motor feels hotter than usual to the touch, it could indicate that the motor is working harder than it should or that there is an issue with its cooling system. Thirdly, a motor that frequently trips the circuit breaker or blows fuses clearly indicates a malfunction. This could be caused by an electrical fault within the motor or an overload due to a faulty component. Furthermore, a damaged electric motor may exhibit reduced performance or a noticeable decrease in power output. This can be observed as a decrease in speed or torque produced by the motor, or even a complete inability to start or function properly. Lastly, excessive vibration or shaking of the motor may indicate misalignment or a problem with its mounting. If not addressed promptly, this can lead to further damage. If any of these signs are noticed, it is recommended to immediately cease using the motor and seek the assistance of a qualified technician or electrician to diagnose and repair the issue. Ignoring or continuing to use a damaged motor can result in further damage and potentially dangerous situations.

- Q: What are the advantages of using ceramic components in concrete pump spare parts?

- Using ceramic components in concrete pump spare parts offers several advantages. Firstly, ceramic materials are renowned for their exceptional durability and resistance to wear. Given the high pressure and intense forces that concrete pumps operate under, it is crucial to have components that can withstand such conditions. Ceramic parts possess superior hardness and strength, making them highly resistant to wear and extending the lifespan of spare parts. Secondly, ceramic components boast excellent corrosion resistance. Concrete consists of various chemicals and substances that can corrode metals. By utilizing ceramic parts, the risk of corrosion is significantly reduced, ensuring the longevity and reliability of the concrete pump spare parts. Furthermore, ceramic materials exhibit low friction coefficients. Consequently, when ceramic components are incorporated into concrete pumps, there is less friction between moving parts. This results in reduced energy consumption and increased efficiency. Ultimately, this can lead to cost savings and improved overall performance of the concrete pump. Moreover, ceramic parts possess high thermal resistance. Concrete pumps generate substantial heat during operation, which can potentially damage or deform certain components. However, ceramic materials can withstand high temperatures without compromising their structural integrity. This ensures the reliability and safety of the concrete pump. Lastly, ceramic components demonstrate excellent dimensional stability. They are less susceptible to expansion or contraction caused by temperature changes. This feature guarantees that spare parts maintain their shape and fit precisely within the concrete pump. Consequently, this precision fitting helps minimize leakage and maintain the pump's efficiency. In summary, the utilization of ceramic components in concrete pump spare parts offers exceptional durability, corrosion resistance, low friction, high thermal resistance, and dimensional stability. These advantages contribute to an increased lifespan, improved performance, reduced maintenance costs, and enhanced overall efficiency of the concrete pump.

- Q: Can I reuse old concrete pump spare parts?

- Reusing old concrete pump spare parts is a possibility, depending on their condition. In the event that the spare parts are in good working order and successfully pass the required inspections, they can be reused to cut costs and minimize waste. Nevertheless, it is crucial to verify that the recycled spare parts are suitable for the specific model and type of concrete pump in use. Seeking advice from a professional or the manufacturer is advised in order to ascertain the safety of reusing the old spare parts.

Send your message to us

Concrete Pump Sponge Ball DN150 with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords