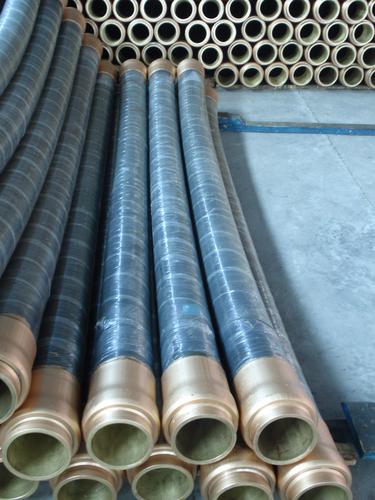

Concrete Pump Rubber End Hose DN125 with Stable Performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1. Specification

Dn125 concrete pump rubber hose

1.Size:5 inch

2.Steel hose

3.2 or 4 piles of steel wires for your choose.

2. Application

1.Applacation:delivery concrete

2.Suitable for the various :Schwing, CIFA,PM, Zoomlion ,SANY and so on.

3. Package

Put into containers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce Concrete Pump Rubber End Hose DN125 according to customers request?

A4: Yes, we can produce Concrete Pump Rubber End Hose DN125 according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: We have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Image:

- Q: How do I properly maintain and replace hydraulic cylinders in concrete pump spare parts?

- Proper maintenance and replacement of hydraulic cylinders in concrete pump spare parts requires a systematic approach. Firstly, regular inspections should be conducted to identify any signs of wear, leakage, or damage. It is important to clean the cylinders regularly to remove any debris or contaminants that can cause premature failure. To maintain the hydraulic cylinders, it is crucial to follow the manufacturer's recommendations for lubrication and fluid changes. Ensure that the hydraulic fluid levels are checked and maintained within the specified range. Additionally, monitor the pressure and temperature of the system to detect any abnormal conditions that may indicate a problem with the cylinders. When it comes to replacement, it is essential to use genuine and high-quality hydraulic cylinders that meet the specifications of the concrete pump. Consult the manufacturer's guidelines for the correct procedure for removing and installing the cylinders. Proper alignment and adjustment of the cylinders are crucial to ensure their optimal performance and longevity. In summary, proper maintenance involves regular inspections, cleaning, lubrication, and monitoring of the hydraulic system. Replacement should be done with genuine parts and following the manufacturer's guidelines. By following these steps, you can ensure the reliable and efficient operation of hydraulic cylinders in concrete pump spare parts.

- Q: Can I get spare parts for both concrete pumps with and without emergency stop systems?

- Yes, you can get spare parts for both concrete pumps with and without emergency stop systems. Most manufacturers and suppliers of concrete pumps offer a wide range of spare parts that are compatible with various models and types of pumps. These spare parts include components like hoses, pipes, valves, seals, and other essential parts that may need replacement due to wear and tear or damage. Whether your concrete pump has an emergency stop system or not, you should be able to find the necessary spare parts to keep your pump running smoothly. However, it is important to note that the availability of specific spare parts may vary depending on the brand, model, and age of your concrete pump. To ensure you get the right spare parts, it is advisable to consult the manufacturer or supplier of your concrete pump. They can provide you with a comprehensive list of spare parts and guide you in selecting the appropriate ones for your specific pump. Additionally, they may also be able to assist you with any technical support or troubleshooting related to your concrete pump.

- Q: How often should hopper screens be cleaned or replaced?

- It is important to clean or replace hopper screens regularly, usually every 3 to 6 months, depending on how often they are used and the type of materials being processed. Keeping the hopper screens clean is crucial for maintaining peak performance and preventing clogs or obstructions. If the screens become excessively dirty or damaged, they should be replaced immediately to avoid interruptions in material flow and potential equipment damage. Regularly maintaining and inspecting the hopper screens will help extend their lifespan and ensure the entire system operates smoothly.

- Q: What are the signs of a clogged or damaged hydraulic filter?

- Some signs of a clogged or damaged hydraulic filter may include decreased hydraulic system performance, increased noise or vibration, higher operating temperatures, and contamination of the hydraulic fluid.

- Q: Is the main pump of the concrete pump electric control or hydraulic control?

- Closed main oil pump behind the charge pump to provide a constant pressure to the displacement of the electromagnet by the current control output pressure to achieve the main pump pressure and pumping the commutation.

- Q: How can a faulty battery affect the operation of the pump?

- A faulty battery can significantly affect the operation of a pump. Firstly, a faulty battery may not provide enough power to the pump, resulting in slow or weak pumping action. This can impact the pump's ability to generate the necessary pressure or flow rate, leading to inefficient or ineffective operation. Additionally, a faulty battery may cause intermittent power supply to the pump. This can result in inconsistent pumping action, with the pump starting and stopping sporadically. Such interruptions can create inefficiencies, reduce the pump's performance, and potentially cause damage to the equipment or system being operated. Furthermore, a faulty battery may not hold a charge for an extended period. This can limit the pump's runtime, requiring frequent recharging or replacement of the battery. In scenarios where a pump is needed for continuous or prolonged usage, a faulty battery can disrupt operations, leading to downtime and reduced productivity. Moreover, a faulty battery can also impact the overall lifespan of the pump. If the battery does not provide the necessary power consistently, the pump may experience strain or excessive wear, potentially shortening its operational life. Overall, a faulty battery can have various adverse effects on the operation of a pump, including reduced performance, inconsistent pumping action, limited runtime, potential damage, and decreased equipment lifespan. Regular maintenance and timely replacement of faulty batteries are crucial to ensure optimal pump performance and longevity.

- Q: Can I get spare parts for concrete pump boom arms and pipes?

- Yes, you can definitely get spare parts for concrete pump boom arms and pipes. There are various suppliers and manufacturers that specialize in providing spare parts for concrete pumps. These spare parts include boom arms, pipes, couplings, gaskets, seals, and other components that are necessary for the proper functioning of a concrete pump. You can search for these spare parts online, where you will find numerous websites and online stores that offer a wide range of options. It is important to ensure that you purchase spare parts from reputable suppliers to ensure their quality and compatibility with your specific concrete pump model. Additionally, there are also local dealers and distributors who stock spare parts for concrete pumps. You can inquire with them or visit their stores to find the required spare parts for your boom arms and pipes. Regular maintenance and replacement of worn-out or damaged parts is crucial for the efficient and safe operation of a concrete pump. By investing in high-quality spare parts, you can extend the lifespan of your equipment and ensure its optimal performance.

- Q: What is the role of a concrete pump hopper grate pin retainer?

- A concrete pump hopper grate pin retainer plays a crucial role in ensuring the safety and functionality of a concrete pump. It is responsible for securing the grate pins in place, which in turn helps to hold the hopper grate firmly in position. The hopper grate is an important component of a concrete pump as it acts as a barrier, preventing any debris or foreign objects from entering the hopper and potentially causing damage to the pump or interfering with the concrete mixing process. The grate pins, located on the sides of the hopper, help to keep the grate securely in place. The concrete pump hopper grate pin retainer is specifically designed to hold the grate pins firmly and prevent them from becoming loose or dislodged during the pumping operation. By keeping the grate securely in position, it ensures that the hopper remains free from any unwanted materials and maintains a smooth and uninterrupted flow of concrete. Furthermore, the pin retainer also helps to prevent potential accidents or injuries by minimizing the risk of the grate coming loose or falling off during operation. This is particularly important when working in construction sites or other high-risk environments, where the safety of workers and equipment is of utmost importance. In summary, the role of a concrete pump hopper grate pin retainer is to provide stability and security to the hopper grate by holding the grate pins firmly in place. It ensures the smooth functioning of the concrete pump by preventing any debris from entering the hopper and maintains a safe working environment by minimizing the risk of accidents or injuries.

- Q: What are the different types of concrete pump rubber pistons?

- There are generally two types of concrete pump rubber pistons: single-layer pistons and double-layer pistons. Single-layer pistons are made of a single piece of rubber and are commonly used for small to medium-sized concrete pumps. On the other hand, double-layer pistons have an additional layer of fabric or wire mesh embedded within the rubber, providing increased durability and strength. These double-layer pistons are typically used for larger concrete pumps and heavy-duty applications.

- Q: Can I get spare parts for concrete pump accessories like remote control systems?

- Yes, spare parts for concrete pump accessories like remote control systems are available. You can find them from various suppliers and manufacturers that specialize in concrete pump accessories.

Send your message to us

Concrete Pump Rubber End Hose DN125 with Stable Performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords