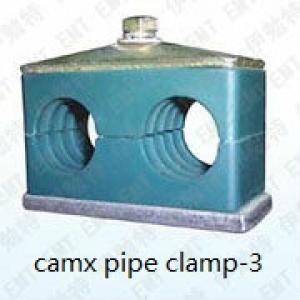

U shape pipe clamp for Concrete Pump with high quanlity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete pump pipe clamp is applicable to concrete pump pipe.Its belongs to concrete pump spare parts

Specifications

stainless steel u bolt clamp steel pipe

1.Manufactur supply directly.

2.Size:M4-M48.etc

3.ISO,SGS.

4.Grade:201,304,316...

stainless steel u bolt clamp steel pipe

Size:stainless steel u-bolts

M6x16-50

M8x20-100

M10x20-100

M12x20-100

M14x30-100

M16x30-100

M18x40-100

M20x40-100

M22x50-100

M27x50-100

M30x50-100

M36x50-100

material:stainless steel

201

304 0Cr18Ni9 304L 00Cr19Ni10

321 0Cr18Ni9Ti 316 0Cr17Ni12Mo2

316L 00Cr17Ni14Mo2 310S 0Cr25Ni20

surface:bright

Tolerance: +/-0.015mm

Grade: 4.6 4.8 5.6 5.8 6.8,etc

DN125 Concrete Pump Clamp Coupling

Type-HD

| 1.5" clamp HD |

2" clamp HD |

| 3" clamp HD |

| 4" clamp HD |

| 3"clamp HD (adjustable) |

| 4"clamp HD (adjustable) |

| 2.5" clamp HD |

| 5" clamp HD |

| 5" clamp HD (adjustable) |

Type-Bolt& snap

Bolt Clamp 2" |

| Bolt Clamp 3" |

| Bolt Clamp 4" |

| Bolt Clamp 5" |

| Bolt Clamp 6" |

| Bolt Clamp Boom Bracket Type 5" |

| Two Bolts Boom Clamp 5" |

| Snap Clamp 2" |

| Snap Clamp 3" |

| Snap Clamp 4" |

| Snap Clamp 4.5" |

| Snap Clamp 5" |

| Snap Clamp 6" |

- Q: What are the signs of wear and tear in concrete pump spare parts?

- Concrete pump spare parts may exhibit signs of wear and tear, which should not be overlooked. Some indicators include: 1. Surface damage: Cracks, dents, or scratches on pipes and hoses can signify wear and tear, particularly if they are extensive or deep. 2. Corrosion: Metal components like couplings or clamps may display signs of corrosion such as rusting or pitting, which can weaken the part and affect its functionality. 3. Leaks: Notable leaks in seals or gaskets can suggest wear and tear. Material degradation or improper installation can cause leaks, impacting the pump's efficiency and performance. 4. Decreased performance: Wear and tear in concrete pump spare parts can result in reduced overall performance. For instance, worn-out wear plates can diminish pumping capacity or increase energy consumption. 5. Heightened noise or vibrations: If noise levels or vibrations intensify while operating the concrete pump, it may indicate wear and tear in the spare parts. Imbalances, misalignments, or loose components can negatively affect the pump's performance and lifespan. 6. Excessive wear on moving parts: Moving parts like pistons or cylinders may exhibit excessive wear and tear, such as scoring or grooving on the surface. This can impede the smooth operation of the pump and potentially cause further damage if left unaddressed. Regular inspection and maintenance of concrete pump spare parts are vital to promptly identify and address any signs of wear and tear. Timely replacement or repair of worn-out components can prevent further damage, ensuring the concrete pump operates efficiently and safely.

- Q: What are the performance characteristics of concrete pump?

- Adopt triple pump, open system, hydraulic circuit, without interference, system operation

- Q: How can a faulty concrete pump cylinder affect the pumping process?

- A faulty concrete pump cylinder can have a significant impact on the pumping process. The cylinder plays a crucial role in the concrete pumping system as it is responsible for generating the necessary pressure to push the concrete through the pipes and hoses. One of the main issues caused by a faulty cylinder is a decrease in pumping efficiency. If the cylinder is worn out or damaged, it may not be able to generate sufficient pressure to push the concrete effectively. This can lead to a decrease in the pumping rate and overall productivity of the concrete pumping operation. Furthermore, a faulty cylinder can result in irregular and inconsistent flow of concrete. This can cause blockages or clogs in the pipes, leading to disruptions in the pumping process. These blockages can be time-consuming and costly to remove, as they may require the disassembly of the pumping system to access and clear the blocked area. In addition, a faulty cylinder can cause leaks in the pumping system. These leaks not only waste concrete but also reduce the overall pressure in the system, affecting the ability to pump the concrete to the desired location. Leaks can also lead to a messy worksite, posing safety risks for workers and potentially damaging surrounding structures. Moreover, a faulty cylinder can increase the risk of equipment failure. If the cylinder malfunctions or fails completely, it can cause the entire pumping system to shut down. This can result in significant downtime and delays in the concrete pouring process, leading to additional costs and potential penalties. Overall, a faulty concrete pump cylinder can greatly affect the pumping process by decreasing pumping efficiency, causing irregular flow, promoting leaks, and increasing the risk of equipment failure. Regular maintenance, inspection, and timely replacement of the cylinder are essential to ensure smooth and efficient concrete pumping operations.

- Q: Can concrete pump spare parts be retrofitted to older pump models?

- Yes, concrete pump spare parts can be retrofitted to older pump models. However, it is essential to ensure compatibility and proper installation to guarantee optimal performance and safety. Professional advice and support should be sought to ensure correct retrofitting of spare parts to older pump models.

- Q: What is the purpose of a concrete pump boom?

- The purpose of a concrete pump boom is to efficiently and accurately place concrete in hard-to-reach areas by extending and maneuvering the boom arm to the desired location.

- Q: What are the different types of concrete pump hopper agitator motors?

- There are generally two types of concrete pump hopper agitator motors: electric motors and hydraulic motors. Electric motors are powered by electricity and are commonly used in smaller and portable concrete pumps. Hydraulic motors, on the other hand, are driven by hydraulic power generated by the concrete pump itself and are typically used in larger and stationary concrete pumps.

- Q: How often should concrete pump clamps be inspected and replaced?

- To maintain proper functioning and detect any wear or damage, it is crucial to conduct regular inspections of concrete pump clamps. The inspection frequency will depend on factors like usage frequency, concrete type, and working conditions. As a general rule, it is advisable to inspect the clamps at least once a month or after every 100 hours of operation, whichever occurs first. This proactive approach will help identify any potential problems early on, preventing them from escalating into major issues. Furthermore, it is essential to visually examine the clamps before each use for any visible signs of damage or wear. This includes checking for cracks, deformations, and loose or missing bolts. The lifespan of concrete pump clamps can vary depending on factors such as clamp quality, intensity of use, and maintenance practices. However, as a general guideline, it is recommended to replace the clamps every 1-2 years or sooner if significant wear or damage is evident. Regular inspections and timely replacements of concrete pump clamps are crucial for ensuring safe and efficient pumping operations. Taking a proactive approach and promptly addressing any potential issues is always preferable to avoid costly repairs or accidents.

- Q: How often should concrete pump filters be inspected and replaced?

- Regular inspections of concrete pump filters are recommended, ideally once a week. The replacement frequency will vary based on factors such as pump type, concrete quality, and working conditions. Typically, clogged or inefficient filters should be replaced. This can happen every few weeks to a few months. It is essential to keep filters clean and functional to avoid blockages, improve pump performance, and prolong equipment lifespan.

- Q: What is the function of a concrete pump water pump?

- The function of a concrete pump water pump is to supply water to the concrete pump system, aiding in the smooth and efficient operation of the equipment.

- Q: How long does it take to replace a specific concrete pump spare part?

- The time it takes to replace a specific concrete pump spare part can vary depending on several factors. Firstly, the complexity and size of the part will play a role in the time required for replacement. Simple and smaller parts may be replaced relatively quickly, while larger and more intricate parts may take longer. Secondly, the availability of the spare part is crucial. If the part is readily available and in stock, the replacement process can be expedited. However, if the part needs to be ordered or sourced from a supplier, there may be a delay in receiving it, which will extend the overall replacement time. Furthermore, the expertise and experience of the person or team performing the replacement will impact the duration as well. Trained and skilled professionals will likely be able to complete the replacement more efficiently compared to those with limited knowledge or experience. Lastly, unforeseen complications or issues during the replacement process can also affect the time required. It is possible that additional repairs or adjustments may be needed, which could prolong the replacement time. In summary, the time it takes to replace a specific concrete pump spare part depends on the complexity and size of the part, its availability, the expertise of the individuals performing the replacement, and any unforeseen complications that may arise. Therefore, it is challenging to provide an exact timeframe without considering these factors.

Send your message to us

U shape pipe clamp for Concrete Pump with high quanlity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords