Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 1MTR Thick 4.1MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

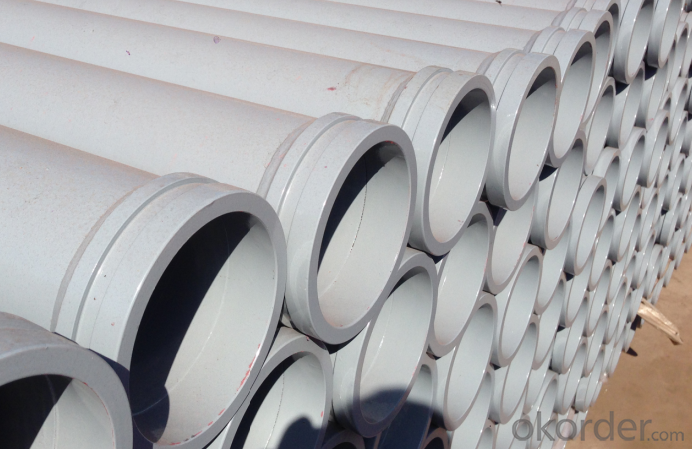

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

Mainly adopt carbon steel high wear resistant steel, and other material upon your request.

Service life:7000-80000 CBM Concrete.

Possess quality certification of ISO 9001:2000. Can pass CE test.

Normal and female/male flanges are both available to suit for normal or high pressure concrete pumping.

We can supply OEM service and can also produce according to your requirements.

Total series of concrete pump pipes for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

Product Specifications:

Dimension: DN125

Length: 1m

Thickness: 4.1mm

Material: ST52

Characteristics: double-ends flange

Package: Seaworthy packing or as customers’ request.

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products :

- Q: Are there any specific brands or manufacturers that are recommended for concrete pump spare parts?

- Yes, there are several brands and manufacturers that are recommended for concrete pump spare parts. Some of the most reputable ones include Schwing, Putzmeister, Sany, and Zoomlion. These brands have a proven track record for producing high-quality and durable spare parts that are compatible with various concrete pump models. It is always advised to consult with professionals or experts in the industry to determine the most suitable brand or manufacturer for specific concrete pump spare parts.

- Q: What are the potential risks of using non-standard or modified hydraulic components in concrete pump spare parts?

- The potential risks of using non-standard or modified hydraulic components in concrete pump spare parts include compromised safety and performance. Non-standard or modified components may not meet the necessary specifications or standards required for safe and efficient operation. This can result in increased wear and tear, reduced reliability, and potential failures, leading to accidents, injuries, or damage to the equipment. Additionally, the use of non-standard components may void warranties and make it difficult to find replacement parts in the future. It is crucial to use approved and genuine hydraulic components to ensure the proper functioning and longevity of the concrete pump.

- Q: Are there any specific guidelines for the disposal of old or damaged concrete pump spare parts?

- Yes, there are specific guidelines for the disposal of old or damaged concrete pump spare parts. It is recommended to contact local waste management authorities or recycling facilities to inquire about proper disposal methods. In many cases, recycling concrete pump spare parts is encouraged to reduce environmental impact.

- Q: What is the difference between concrete pump and ground pump?

- The pump is actually the day Linuo arm frame of concrete pump boom is known, a few day, after mixing through the boom pump, the efficiency is very high

- Q: How often should concrete pump gearboxes be inspected and maintained?

- Concrete pump gearboxes should be inspected and maintained regularly to ensure their optimal performance and longevity. The frequency of inspections and maintenance depends on several factors such as the usage of the concrete pump, the working environment, and the manufacturer's recommendations. In general, it is recommended to have a thorough inspection and maintenance at least once a year. However, if the concrete pump is used extensively or operated in harsh conditions, more frequent inspections may be necessary. This can be done every six months or even quarterly. Regular maintenance should include checking for any signs of wear and tear, lubricating gears and bearings, and replacing any worn-out or damaged parts. It is important to follow the manufacturer's guidelines and consult with a professional if there are any concerns or specific requirements for the concrete pump gearbox. By conducting regular inspections and maintenance, potential issues can be identified early on and addressed promptly, ensuring the smooth and efficient operation of the concrete pump gearboxes.

- Q: What are the common challenges in sourcing spare parts for stationary concrete pumps?

- Sourcing spare parts for stationary concrete pumps can present various common obstacles. Firstly, availability poses a significant challenge. Depending on the concrete pump's brand and model, locating the exact spare parts needed can prove difficult. Some manufacturers lack a widespread distribution network, making it challenging to promptly locate the required spare parts. This difficulty is intensified if the concrete pump is an older model or if the manufacturer has ceased production. Another significant challenge is cost. Spare parts for stationary concrete pumps can be pricey, particularly when sourced directly from the manufacturer. Alongside the initial cost, additional expenses like shipping, customs duties, and taxes further escalate the overall cost of acquiring spare parts. Ensuring quality assurance is a crucial aspect when sourcing spare parts. It is vital to verify that the sourced spare parts are of high quality and compatible with the specific make and model of the concrete pump. Inferior spare parts can result in performance issues, breakdowns, and potential safety hazards, detrimentally impacting the overall efficiency and lifespan of the concrete pump. Timing also plays a pivotal role in spare parts sourcing. When a concrete pump malfunctions, it can cause delays in construction projects, leading to extra expenses and potential penalties. Therefore, swiftly and efficiently finding spare parts is essential to minimize downtime and ensure smooth operations. Additionally, language and communication barriers can present challenges. If the spare parts manufacturer or supplier is situated in a different country or speaks a different language, effective communication can be problematic. This can lead to misunderstandings, delays, and difficulties in accurately conveying specific spare parts requirements. To overcome these challenges, it is advisable to collaborate with reputable suppliers specializing in concrete pump spare parts. These suppliers often maintain a vast inventory of spare parts, ensuring availability and reducing the risk of delays. Furthermore, establishing strong relationships with local distributors or authorized service centers can streamline access to spare parts and technical support. Regular maintenance and proactive planning can also help mitigate the challenges of sourcing spare parts for stationary concrete pumps. Maintaining an inventory of essential spare parts and components can minimize downtime and ensure smooth operations.

- Q: What are the advantages of using genuine spare parts for my concrete pump?

- There are several advantages to using genuine spare parts for your concrete pump. Firstly, genuine parts are specifically designed and manufactured to fit and function perfectly with your pump, ensuring optimal performance and reliability. These parts are made with high-quality materials and undergo rigorous testing, providing durability and longevity. Secondly, using genuine spare parts helps to maintain the integrity and efficiency of your concrete pump. Non-genuine parts may not meet the same standards, leading to decreased performance, increased downtime, and potentially costly repairs. Genuine parts also come with warranties, providing peace of mind and assurance of their quality. Moreover, using genuine spare parts ensures compatibility with the rest of your equipment and reduces the risk of damage or malfunction. Mixing non-genuine parts with genuine ones can lead to mechanical issues, which can be avoided by sticking to genuine replacements. Lastly, using genuine spare parts helps to retain the value of your concrete pump. When it comes to selling or trading in your equipment, having genuine parts installed increases its market value, as it indicates that the pump has been properly maintained and cared for. Overall, investing in genuine spare parts for your concrete pump guarantees superior performance, longevity, compatibility, and value, making it a wise and cost-effective choice in the long run.

- Q: Can I get spare parts for concrete pump wear plates and cutting rings?

- Yes, spare parts for concrete pump wear plates and cutting rings are typically available. They can be purchased from various suppliers and manufacturers specializing in construction equipment parts.

- Q: What are the advantages of using ceramic components in concrete pump spare parts?

- There are several advantages of using ceramic components in concrete pump spare parts. Firstly, ceramic materials are known for their exceptional durability and wear resistance. Concrete pumps operate under high pressure and require components that can withstand the intense forces and abrasion. Ceramic parts have superior hardness and strength, making them highly resistant to wear and extending the lifespan of the spare parts. Secondly, ceramic components have excellent corrosion resistance. Concrete contains various chemicals and substances that can be corrosive to metals. By using ceramic parts, the risk of corrosion is significantly reduced, ensuring the longevity and reliability of the concrete pump spare parts. Additionally, ceramic materials have low friction coefficients. This means that when ceramic components are used in concrete pumps, there is less friction between the moving parts, resulting in reduced energy consumption and increased efficiency. This can lead to cost savings and improved overall performance of the concrete pump. Furthermore, ceramic parts have a high thermal resistance. Concrete pumps generate heat during operation, and this can cause damage or deformation to certain components. However, ceramic materials can withstand high temperatures without losing their structural integrity, ensuring the reliability and safety of the concrete pump. Lastly, ceramic components have excellent dimensional stability. They are less prone to expansion or contraction due to temperature changes, ensuring that the spare parts maintain their shape and fit accurately within the concrete pump. This precision fitting helps to minimize leakage and maintain the efficiency of the pump. In summary, the advantages of using ceramic components in concrete pump spare parts include exceptional durability, corrosion resistance, low friction, high thermal resistance, and dimensional stability. These benefits contribute to increased lifespan, improved performance, reduced maintenance costs, and enhanced overall efficiency of the concrete pump.

- Q: What are the signs of a malfunctioning gearbox?

- There are several signs that can indicate a malfunctioning gearbox in a vehicle. One of the most common signs is difficulty shifting gears. If you notice that it is becoming increasingly difficult to shift gears smoothly or if you experience grinding or clunking noises when shifting, it could be a sign of a problem with the gearbox. Another sign of a malfunctioning gearbox is slipping gears. This occurs when the gearbox fails to stay in the selected gear and instead slips into a different gear, often resulting in a loss of power or acceleration. You may also notice that the engine RPMs increase without a corresponding increase in speed. Leaking transmission fluid is another indicator of a faulty gearbox. Transmission fluid is essential for lubricating and cooling the gears, so any leakage can lead to overheating and damage to the gearbox components. If you notice red or brown fluid underneath your vehicle, it could be a sign of a leaking gearbox. Unusual noises, such as whining, humming, or clunking sounds, can also be a sign of gearbox issues. These noises may occur while driving, particularly during acceleration or deceleration, and can indicate problems with the gears or bearings within the gearbox. Finally, if you experience a burning smell coming from the engine or gearbox area, it could be a sign of overheating or excessive friction within the gearbox. This can be caused by low or contaminated transmission fluid, worn-out gears, or a malfunctioning cooling system. If you notice any of these signs, it is important to have your vehicle inspected by a qualified mechanic as soon as possible. Ignoring gearbox issues can lead to further damage and potentially costly repairs.

Send your message to us

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 1MTR Thick 4.1MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords