TPO Single-ply Roofing System 9 Colors Available

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TPO Single-ply Roofing System 9 Colors Avaliable

Product Introduction of TPO Single-ply Roofing System

TPO membrane is a flexible Thermoplastic Polyolefin (FPO) roofing membrane made from the incorporation of a ethylene propylene rubber into a polypropylene matrix. The membrane is specifically formulated for long-term weather resistance without plasticizers.

We produce 4 types of TPO membrane to satisfy all the needs of different applications.

1.Polyester Fleece Backing Thermoplastic Polyolefin Waterproof Membrane

2.Polyester Mesh Reinforced Thermoplastic Polyolefin Waterproof Membrane

3. Homogeneous Thermoplastic Polyolefin Waterproof Membrane

4. Self Adhesive TPO Membrane

Features of TPO Single-ply Roofing System

-TPO membrane can be overlapped and hot-air welded, offers exceptionally strong seam.

-Long-term weatherability, excellent durability, the service life of TPO is more than 50 years.

-High solar reflective, energy saving, environmental friendly.

-Excellent durability and root resistance, can be used as root barrier for green roof.

-Excellent the same low temperature resistance as rubber materials which can keep flexible at -40℃.

-Excellent chemical resistance to acids, alkali and salts.

-Available in more than 9 colors.

Applications of TPO Single-ply Roofing System

-Various roofing waterproof projects, such as industrial and civil buildings, public constructions

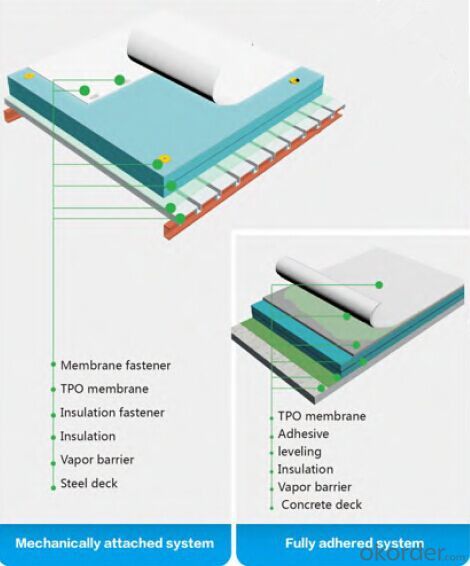

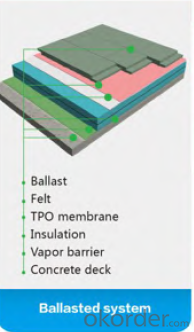

- Full adhered system for concrete substrate or mechanically attached systems or ballasted system.

Propoties of TPO Single-ply Roofing System

Item | Requirement | Test Method | ||

Thickness, min, mm | Sheet-overall | ≥1.0 | ASTM D6878 | |

Coating over fabric or scrim, weathering side only | ≥0.305 | ASTM D751 | ||

Breaking strength, min, N | ≥976 | ASTM D751 | ||

Elongation at reinforcement break, min, % | ≥15 | ASTM D751 | ||

Tensile strength,min, N | ≥245 | ASTM D751 | ||

Brittleness point, max, °C | ≤-40 | ASTM D2137 | ||

Ozone resistance | no cracks | ASTM D1149 | ||

Properties after heat aging | Breaking strength, % min | ≥90 | ASTM D573 | |

Elongation at reinforcement break, % min | ≥90 | ASTM D573 | ||

Tearing strength, % min | ≥60 | ASTM D573 | ||

Weight change (mass), max % | ≤±1 | ASTM D573 | ||

Linear dimensional change, max, % | ≤±1 | ASTM D1204 | ||

Water absorption, max, mass % | ≤±3.0 | ASTM D471 | ||

Factory seam strength, min, N | ≥290 | ASTM D751 | ||

Weather resistance | Visual inspection | - | ||

Packaging of TPO Single-ply Roofing System

Thickness | Roll Size | Rolls / Wooden Crate | Wooden Crate / 20’ Container |

1.2 mm | 15 m2 | 25 | 20~25 |

20 m2 | 25 | ||

30 m2 | 25 | ||

1.5 mm | 15 m2 | 25 | |

20 m2 | 25 | ||

30 m2 | 20 |

Above quantities are indicative only. We can produce it according to your demands.

Storage of TPO Single-ply Roofing System

TPO material should be stored in well-ventilated place and avoid being exposed to the sun or rain. The temperature in stored places can not be higher than 45° C. It only can be put horizontally in five-level. It has to be avoided acid, alkali, oil and organic solvents. The shelf life is 1 year.

Transportation of TPO Single-ply Roofing System

TPO material should avoid inclination or lateral drift during transportation. When necessary, covering with felted fabric.

Application of TPO Single-ply Roofing System

We not only provides TPO waterproofing membrane, but also dedicates to integrated roofing systems. TPO single ply roofing waterproof system includes mechanically attached roofing system, fully adhered roofing system and ballasted roofing system.

Application Methods of TPO Single-ply Roofing System

● For Mechanically Attached Roofing System

Before application, spread TPO membranes on substrate in advance. Install TPO membranes perpendicular to steel deck ribs on the substrate without distortions according to the flange. The overlapping width is 120 mm. The minimum overlapping distance of membrane short side direction is 50 mm. Fasteners are installed according to designed position. Hot-air welding is adopted for laps with 40 mm welding width.

● For Fully Adhered Roofing System

Before application, spread TPO membranes on substrate in advance. Install TPO membranes on the substrate without distortions according to the flange. The overlapping width should be more than 50 mm. Hot-air welding is adopted for laps with 40 mm welding width. Professional adhesives need to be used on both underside and substrate surfaces to adhere and maintain.

● For Ballasted Roofing System

Before application, spread TPO membranes on substrate in advance. Install TPO membranes on the substrate without distortions according to the flange. The overlapping width should be more than 50 mm. Hot-air welding is adopted for laps with 40 mm welding width.

Attentions

● TPO membranes reflect heat and light, wearing protective clothing (long-sleeved shirt, long-barreled trousers), and wearing a filter to protect the skin and eyes from UV-induced damage.

● Security measures for roof perimeter are necessary when application. Sheet surface is slippery when wet, taking care to avoid slide.

● Sealants and adhesives are flammable containing solvents. They will be dangerous when exposure to heat, even have the possibility to catch fire and explode.

● Sealants, adhesives, cleaners should be avoided contacting with skin and eyes.

● No smoking during application.

FAQ

1. What’s your production ability of TPO membrane per year?

We own the largest EPDM production line in China. Our product ability of TPO membrane reaches 500million square meters.

2. How's your products quality?

Our TPO is with the top quality at home and abroad. Our quality is much higher than Chinese standard, they can satisfy the certification of CE, GOST-R, FM.

3. What's the service life of your TPO membrane?

The service life of our TPO membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 4000M2.

5. Can you provide free of charge samples for testing quality?

Yes, we’re very glad to send you free of charge samples for checking. You just need to pay for the freight cost.

6. How do you protect TPO membrane in transportation?

We package TPO rolls by PE bag, then 20~25 rolls will be packed into one big wooden crate.

7. Can you customize TPO membrane?

Yes, we’re very glad to customize TPO membrane according to your requirement. We can do more than 9 colors, and customize the thickness and width according to your requirement.

Photos

- Q: Can a waterproofing membrane be applied on any surface?

- A waterproofing membrane can be applied on a variety of surfaces, but it is important to consider the specific characteristics and requirements of each surface before proceeding. While many waterproofing membranes are versatile and can adhere to different materials, it is recommended to consult with a professional or manufacturer to ensure compatibility and optimal performance. For concrete surfaces, waterproofing membranes can be applied to prevent water penetration and protect against moisture damage. These membranes are typically designed to adhere to concrete and provide a barrier against water and vapor transmission. However, it is important to properly prepare the concrete surface by cleaning, repairing any cracks or imperfections, and ensuring a smooth and even substrate for the membrane. Similarly, waterproofing membranes can be applied to masonry surfaces such as brick or stone. These surfaces may require additional preparation, such as removing loose mortar or debris, and may benefit from a primer to enhance adhesion. Additionally, certain types of waterproofing membranes may be more suitable for these surfaces depending on their porosity and texture. Waterproofing membranes can also be applied to wood surfaces, such as decks or balconies, to protect against moisture damage and extend their lifespan. However, it is important to select a membrane specifically designed for wood surfaces as they may require additional flexibility to accommodate the natural movement and expansion of the wood. In summary, while a waterproofing membrane can be applied on various surfaces, it is crucial to consider the specific characteristics and preparation requirements of each surface to achieve optimal results. Consulting with a professional or manufacturer can help determine the most suitable membrane and application method for a particular surface.

- Q: Can waterproofing membranes be used on concrete pools?

- Indeed, concrete pools can benefit from the utilization of waterproofing membranes. These membranes are purposely engineered to serve as a defense against water infiltration and can be administered on a multitude of surfaces, including concrete. Over time, concrete pools are prone to water seepage as a result of cracks or degradation. By applying a waterproofing membrane, the occurrence of such predicaments can be mitigated. Typically, the membrane is administered to the inner surface of the pool, thereby establishing a seamless and impervious seal. It is imperative to select a top-notch waterproofing membrane that is specifically formulated for swimming pool use to guarantee enduring and efficacious outcomes.

- Q: Can a waterproofing membrane protect against mold or mildew growth?

- Yes, a waterproofing membrane can help protect against mold or mildew growth. Mold and mildew thrive in damp and moist environments, and a waterproofing membrane creates a barrier that prevents water from seeping into the building structure. By keeping the area dry, it greatly reduces the chances of mold or mildew growth. Additionally, waterproofing membranes often have anti-microbial properties that inhibit the growth of mold and mildew even further. However, it's important to note that while a waterproofing membrane can provide significant protection against mold and mildew, it is not a foolproof solution. Proper ventilation and regular maintenance are also essential to prevent these issues.

- Q: Can a waterproofing membrane be used for a basement?

- Basements can indeed benefit from the use of a waterproofing membrane. It is highly recommended to employ this method in order to avoid water infiltration and the accumulation of moisture. A waterproofing membrane consists of a thin layer of material that is applied to the walls and floor of the basement, serving as a barrier against water. This layer acts as a protective shield, preventing water from penetrating the walls and causing harm to the foundation and interior of the basement. Furthermore, the use of a waterproofing membrane can also decrease the likelihood of mold and mildew growth, as it maintains a dry and moisture-free environment in the basement. In conclusion, the utilization of a waterproofing membrane is an effective remedy for ensuring waterproof basements and providing a safe and dry living space.

- Q: Can a waterproofing membrane be used for a retaining wall?

- Yes, a waterproofing membrane can be used for a retaining wall. Retaining walls are typically used to hold back soil or other materials, and they are often subjected to moisture and water pressure. A waterproofing membrane can provide an effective barrier to prevent water from seeping through the retaining wall and causing damage. It can help to maintain the structural integrity of the wall and extend its lifespan. However, it is important to ensure that the waterproofing membrane chosen is suitable for the specific conditions and requirements of the retaining wall. Professional advice and proper installation techniques should be followed to ensure the effectiveness and longevity of the waterproofing membrane.

- Q: Can a waterproofing membrane be used in boat decks or marinas?

- Yes, a waterproofing membrane can be used in boat decks or marinas. It is commonly used to protect the underlying structure from water damage and provide a durable, watertight barrier that helps prevent leaks and deterioration.

- Q: Can waterproofing membranes be used on both horizontal and vertical surfaces?

- Yes, waterproofing membranes can be used on both horizontal and vertical surfaces.

- Q: Can waterproofing membranes be used in basements?

- Yes, waterproofing membranes can be used in basements. Waterproofing membranes are specifically designed to provide a barrier against water penetration and are commonly used in basements to prevent moisture and water seepage. These membranes are typically made of materials such as rubber, bitumen, or polyethylene, and are applied to the basement walls and floors to create a waterproof seal. By preventing water from entering the basement, these membranes help to protect the foundation, walls, and interior spaces from water damage, mold, and other moisture-related issues. Additionally, waterproofing membranes can also be used in combination with other waterproofing techniques such as drainage systems and sump pumps to provide comprehensive protection against water infiltration in basements.

- Q: Construction Measures for Waterproof Coil in Winter

- High polymer modified asphalt waterproofing membrane to hot melt construction is more simple, the construction temperature can be within -10 ℃. 1. Base treatment agent to be volatile completely, full. Winter construction often use solvent-based treatment agent, one is free from frozen, the second is easy to operate. Low temperature in winter, solvent evaporation slow, so should strictly control the solvent drying time, winter in 10h above the basic volatile full, finished, and then arrange the hot melt coil process to prevent the fire.

- Q: Can a waterproofing membrane be used in conjunction with tile or stone installations?

- Certainly! When installing tile or stone, it is highly recommended to utilize a waterproofing membrane. This membrane serves as a barrier, preventing water from seeping into the underlying layers and causing damage. It is especially beneficial in wet areas, such as bathrooms, showers, and kitchen backsplashes. There are different types of waterproofing membranes available, such as liquid-applied, sheet, and fabric membranes. These can be applied to the substrate before installing the tile or stone, creating a waterproof layer that keeps the area dry and free from water-related issues. In addition to safeguarding against water damage, a waterproofing membrane also helps to prevent the growth of mold and mildew, which can be detrimental to both the installation and the health of those using the space. It is essential to note that proper installation of the waterproofing membrane is crucial for its effectiveness. Following the guidelines and best practices provided by the manufacturer ensures a tight seal and complete coverage. Overall, integrating a waterproofing membrane with tile or stone installations is a prudent decision. It enhances the project's durability and longevity while providing peace of mind against potential water damage.

Send your message to us

TPO Single-ply Roofing System 9 Colors Available

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords