Tabel-Formwork for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

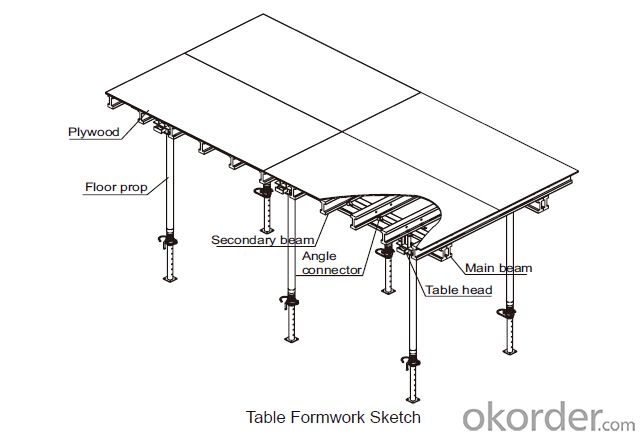

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: What are the common design considerations for steel formwork in bridge construction?

- When discussing steel formwork in bridge construction, there are several important factors that must be taken into consideration. These factors include: 1. Ensuring Strength and Stability: Engineers must design the steel formwork to withstand the various loads it will encounter during construction, including the weight of wet concrete and any equipment used. The formwork needs to provide sufficient strength and stability to ensure the safety of workers and the integrity of the structure. 2. Emphasizing Durability and Reusability: Designing the steel formwork to be durable and reusable is essential. It should be able to endure multiple uses without significant deterioration, which helps reduce costs and minimize waste. 3. Allowing for Flexibility and Adaptability: The design of the steel formwork should be flexible and adaptable to accommodate different bridge geometries and dimensions. This is particularly important as each bridge may have unique design requirements. 4. Prioritizing Ease of Assembly and Disassembly: The formwork should be designed for easy assembly and disassembly, as this expedites the construction process and reduces labor costs. Quick and efficient assembly and disassembly can also minimize disruptions to traffic flow during construction. 5. Focusing on Safety: Safety is a critical consideration in any construction project, including steel formwork. The design should incorporate safety features to protect workers during assembly, disassembly, and concrete pouring. These features may include guardrails, access platforms, and fall protection systems. 6. Striving for Cost-effectiveness: The design of the steel formwork should aim to be cost-effective. This involves considering factors such as material selection, fabrication methods, and ease of transport and installation. The goal is to optimize the overall cost of the formwork while maintaining its functionality and performance. In conclusion, the design considerations for steel formwork in bridge construction revolve around ensuring strength, stability, durability, reusability, flexibility, adaptability, ease of assembly and disassembly, safety, and cost-effectiveness. By carefully addressing these considerations, engineers can ensure the successful and efficient construction of bridges using steel formwork.

- Q: Can steel formwork be used for precast concrete arches?

- Yes, steel formwork can be used for precast concrete arches. Steel formwork is a versatile and durable material that can be used to create complex shapes and structures, including arches. Steel formwork provides excellent support and stability during the casting process, allowing for the precise and accurate formation of arches. Additionally, steel formwork can be easily customized and adjusted to accommodate different arch designs and dimensions. Its strength and rigidity make it suitable for withstanding the pressure and weight of the concrete during the curing process. Therefore, steel formwork is a preferred choice for constructing precast concrete arches due to its flexibility, strength, and reliability.

- Q: Can steel formwork be used for soundproofing walls?

- Steel formwork is primarily used for creating the structure and shape of concrete walls during construction. While steel formwork is sturdy and durable, it is not specifically designed for soundproofing purposes. Soundproofing walls typically require materials with high acoustic performance and insulation properties to effectively block or absorb sound waves. While steel formwork may offer some level of sound reduction due to its density, it is not sufficient for achieving significant soundproofing results. To effectively soundproof walls, it is recommended to use specialized materials such as acoustic insulation, mass-loaded vinyl, or soundproof drywall, which are designed specifically for this purpose.

- Q: How does steel formwork affect the overall stability of a structure?

- Steel formwork has a significant impact on the overall stability of a structure. Formwork refers to the temporary molds or frameworks used to shape and support wet concrete until it hardens and becomes self-supporting. Steel formwork, in particular, offers several advantages that positively influence the stability and strength of the structure. Firstly, steel formwork provides exceptional strength and durability compared to other materials like wood or plastic. This high strength allows steel formwork to withstand the pressure exerted by the wet concrete without deformation or collapse. Consequently, the structure's stability is enhanced as the formwork maintains its shape and rigidity during the concrete pouring and curing process. Moreover, steel formwork offers better dimensional accuracy and consistency. Its rigidity prevents any movement or shifting, ensuring that the concrete is poured and cured in the desired shape and dimensions. This precision is crucial for maintaining the structural integrity and stability of the final construction. Additionally, steel formwork allows for greater flexibility in design and construction. It can be easily customized and shaped to meet the specific requirements of the structure, enabling architects and engineers to create complex and unique designs. This flexibility enhances the overall stability of the structure by allowing for efficient load distribution and reinforcement placement. Furthermore, steel formwork possesses excellent load-bearing capacity. It can efficiently distribute the weight of the wet concrete, as well as any additional loads applied during construction, such as workers, equipment, or construction materials. This load-bearing capacity ensures that the structure remains stable and can withstand the imposed loads without compromising its integrity. Lastly, steel formwork has a longer lifespan compared to other formwork materials. Its durability and resistance to deterioration increase the overall stability of the structure over time. Steel formwork can be reused multiple times, reducing waste and costs while maintaining the desired stability and quality of the finished construction. In conclusion, steel formwork significantly contributes to the overall stability of a structure. Its strength, dimensional accuracy, flexibility, load-bearing capacity, and longevity ensure that the formwork maintains its shape and rigidity, supporting the wet concrete and allowing it to cure properly. By providing a solid and reliable foundation, steel formwork enhances the stability and strength of the structure, ensuring its long-term durability.

- Q: What are the different types of steel formwork systems available in the market?

- There are several different types of steel formwork systems available in the market, including traditional steel formwork, modular steel formwork, and panelized steel formwork. Traditional steel formwork consists of steel plates or frames that are assembled on-site to create the desired formwork shape. Modular steel formwork is pre-engineered and consists of standardized panels that can be easily assembled and reused. Panelized steel formwork is similar to modular steel formwork but consists of large panels that are interconnected to create the desired formwork shape.

- Q: Can steel formwork be used in industrial construction projects?

- Yes, steel formwork can be used in industrial construction projects. Steel formwork is known for its durability and strength, making it suitable for withstanding the heavy loads and demands of industrial construction. It is also reusable, allowing for cost savings and efficiency in large-scale projects. Additionally, steel formwork provides a smooth finish and precise alignment, ensuring high-quality and accurate construction in industrial settings.

- Q: Can steel formwork be used for both flat and sloped surfaces?

- Yes, steel formwork can be used for both flat and sloped surfaces. Steel formwork is highly versatile and can be easily adjusted or modified to suit different surface shapes and angles. It offers excellent strength and durability, making it suitable for various construction projects that involve both flat and sloped surfaces.

- Q: Can steel formwork be used for structures with high thermal insulation requirements?

- Steel formwork is not typically used for structures with high thermal insulation requirements. This is because steel is a good conductor of heat, meaning it allows heat to easily transfer through it. As a result, using steel formwork in structures that require high thermal insulation would lead to significant heat loss, reducing the overall energy efficiency of the building. To achieve high thermal insulation, materials with good thermal resistance such as insulating concrete forms (ICFs), expanded polystyrene (EPS), or other insulated formwork systems are preferred. These materials have low thermal conductivity and provide a barrier against heat transfer. By using such materials, structures can meet the high thermal insulation requirements and improve energy efficiency. However, it is worth mentioning that steel formwork can still be used in combination with insulation materials to provide structural support and form the shape of the structure. In this case, additional insulation measures, such as applying insulation layers or using insulation inserts, would be necessary to enhance the thermal performance of the structure. Overall, while steel formwork can be suitable for many construction projects, it is not the ideal choice for structures with high thermal insulation requirements.

- Q: What are the different types of release agents used with steel formwork?

- There are several types of release agents used with steel formwork, including petroleum-based agents, water-based agents, silicone-based agents, and wax-based agents. These release agents are applied to the surface of the formwork to prevent the concrete from sticking to it during the pouring and curing process. Each type of release agent has its own advantages and suitability for different applications, depending on factors such as the desired finish, ease of application, and environmental considerations.

- Q: How does steel formwork affect the overall construction timeline?

- The overall construction timeline can be significantly influenced by steel formwork in various ways. Firstly, the durability and strength of steel formwork allow for quicker and more efficient construction processes. Unlike traditional timber formwork, steel formwork can be used multiple times, reducing the effort and time required for dismantling and reassembling. This reusability not only saves time but also reduces the need for additional materials, resulting in lower construction waste and costs. Moreover, steel formwork offers greater design and customization flexibility. Its versatility allows for the easy creation of complex shapes and structures, minimizing the need for extensive modifications or adjustments during construction. This flexibility not only saves time but also enhances overall construction efficiency. Furthermore, steel formwork provides faster concrete curing times due to better temperature and moisture control. This speeds up the concrete setting process and reduces the time needed for removing the formwork. As a result, the construction timeline is shortened, enabling earlier commencement of subsequent construction activities. Additionally, the high load-bearing capacity of steel formwork allows for the simultaneous construction of multiple floors. This parallel construction approach significantly expedites the construction process, reducing the overall timeline. However, it is important to note that although steel formwork offers numerous advantages, its initial setup and installation may require more time compared to other formwork materials. Proper alignment and securing of the steel formwork system may take longer than setting up traditional timber formwork. Nevertheless, this initial time investment is often compensated by the time saved during subsequent construction stages. In conclusion, steel formwork has a positive impact on the overall construction timeline. Its durability, reusability, flexibility, faster curing times, and high load-bearing capacity contribute to faster construction processes, reduced material waste, and increased construction efficiency. Despite the initial setup time, the benefits of steel formwork ultimately result in a more streamlined and accelerated construction timeline.

Send your message to us

Tabel-Formwork for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords