Tabel-formwork for Formwork and Scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

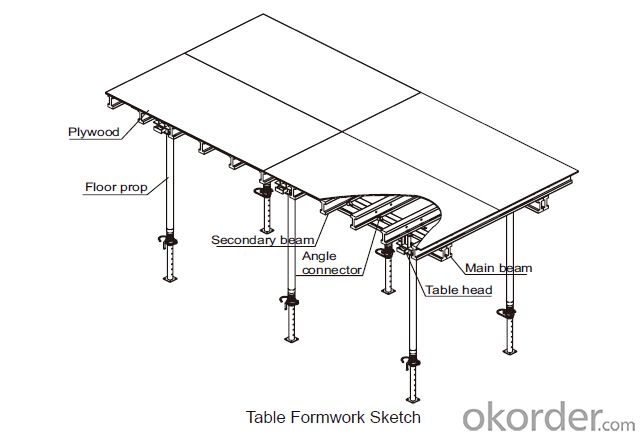

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: How does steel formwork affect the overall construction cost?

- The overall construction cost can be significantly impacted by steel formwork. Although the initial cost of steel formwork may be higher than that of timber or aluminum formwork, it offers various advantages that can lead to cost savings in the long run. To begin with, steel formwork is highly durable and has a longer lifespan when compared to other materials. This implies that it can be used multiple times, reducing the need for new formwork in future projects. Consequently, the cost of purchasing or renting formwork for subsequent projects decreases, resulting in overall cost savings. Furthermore, steel formwork is renowned for its strength and stability. This enables faster construction processes, as it can withstand higher concrete pressures, leading to quicker cycle times. The ability to achieve faster construction speeds can reduce labor costs and shorten the overall construction timeline, resulting in cost savings. Moreover, steel formwork ensures excellent quality and precision in concrete structures. It enables accurate shaping and forming of concrete elements, resulting in better finishes and fewer defects. This can reduce the requirement for additional finishing work, repairs, or rework, leading to cost savings in terms of materials and labor. Additionally, steel formwork enhances safety on construction sites. Its stability and strength enable it to withstand adverse weather conditions and prevent accidents. By ensuring a safe working environment, potential delays and costs associated with accidents or injuries can be minimized. Lastly, steel formwork is known for its versatility and adaptability. It can be easily customized to meet various project requirements, allowing for flexibility in design and construction. This versatility can lead to optimized construction processes and materials, ultimately reducing costs. In conclusion, although the initial cost of steel formwork may be higher, its durability, strength, speed, accuracy, safety, and versatility can result in significant cost savings in terms of reusability, labor, materials, and time. Therefore, steel formwork plays a positive role in the overall construction cost by providing long-term value and efficiency.

- Q: What are the considerations when designing steel formwork for architectural sculptures?

- When designing steel formwork for architectural sculptures, there are several important considerations that need to be taken into account. Firstly, the structural integrity and stability of the formwork is paramount. The formwork must be able to withstand the weight of the concrete or other materials that will be poured into it, as well as any external forces that may be applied during the construction process. This requires careful analysis and engineering to ensure that the formwork is strong enough to support the weight and forces without any risk of collapse. Secondly, the accuracy and precision of the formwork is crucial. Architectural sculptures often require intricate and detailed designs, so the formwork must be able to accurately reproduce these shapes. This may involve using advanced computer-aided design (CAD) software to create precise 3D models of the sculpture, which can then be used to fabricate the formwork. Another consideration is the ease of assembly and disassembly of the formwork. Architectural sculptures can be complex and intricate, so the formwork must be designed in a way that allows for easy assembly and disassembly. This may involve using modular components that can be easily connected and disconnected, as well as incorporating features such as adjustable supports or brackets to accommodate different shapes and sizes. Additionally, the choice of materials for the formwork is important. Steel is a common choice due to its strength and durability, but other materials such as aluminum or fiberglass may also be used depending on the specific requirements of the project. The materials used must be able to withstand the weight and forces applied during construction, as well as any potential exposure to weather or other environmental conditions. Finally, considerations should be made for the aesthetics of the formwork. While the primary function of the formwork is to support the construction process, it is also important that it does not detract from the overall visual impact of the sculpture. This may involve using smooth finishes, hidden connections, or other design techniques to ensure that the formwork remains visually appealing. In conclusion, designing steel formwork for architectural sculptures requires careful consideration of factors such as structural integrity, accuracy, ease of assembly, material selection, and aesthetics. By addressing these considerations, designers can ensure that the formwork is not only functional and safe but also enhances the overall artistic vision of the sculpture.

- Q: How does steel formwork perform in fire-resistant structures?

- Steel formwork performs exceptionally well in fire-resistant structures. The inherent properties of steel, such as its high melting point and strength, make it an ideal material for withstanding high temperatures and structural integrity during a fire event. Firstly, steel formwork is non-combustible, meaning it does not contribute to the spread or intensity of the fire. It does not burn or release harmful gases when exposed to flames, unlike some other construction materials. This characteristic helps to prevent the rapid spread of fire within the structure, providing valuable time for evacuation and fire suppression. Moreover, steel has a high melting point compared to other materials commonly used in formwork, such as wood or plastic. This property allows steel formwork to maintain its structural integrity even when exposed to intense heat. It can withstand temperatures well above 1000°C (1832°F) without significant deformation or collapse, ensuring the stability of the structure and reducing the risk of sudden structural failure during a fire. Additionally, steel formwork has excellent load-bearing capabilities, even at high temperatures. This is crucial in fire-resistant structures as it allows the building to maintain its structural capacity when exposed to fire. The ability of steel formwork to bear the weight of the structure, even when compromised by fire, helps to prevent structural collapse and ensures the safety of occupants and emergency responders. Furthermore, steel formwork is durable and long-lasting, which is important in fire-resistant structures. It can withstand the effects of fire, such as thermal expansion and contraction, without significant damage. This durability ensures that the formwork can be reused or remain in place for future fire events, providing ongoing fire protection for the structure. In conclusion, steel formwork performs exceptionally well in fire-resistant structures. Its non-combustible nature, high melting point, load-bearing capabilities, and durability make it a reliable choice for maintaining the structural integrity and safety of the building during a fire.

- Q: What are the different types of connections used in steel formwork construction?

- Steel formwork construction utilizes various types of connections, each serving a specific purpose. 1. Bolted connections, the most commonly used type, involve securing steel formwork components together using bolts, nuts, and washers. This connection provides a strong and rigid joint that is easy to assemble and disassemble. 2. Welded connections fuse steel formwork components together using heat and pressure. They are ideal for permanent structures or situations requiring high strength and rigidity. However, welded connections are time-consuming and require skilled labor. 3. Clamped connections utilize clamps or brackets to hold steel formwork components together. This connection type is suitable for temporary structures or frequent disassembly/reassembly, as it is quick to assemble and disassemble and does not require specialized skills or equipment. 4. Interlocking connections employ specially designed mechanisms, such as tabs, slots, or grooves, to connect steel formwork components. These connections are commonly used in modular formwork systems, where fast and easy assembly is necessary. 5. Adhesive connections involve bonding steel formwork components together using epoxy or other adhesive materials. This connection type provides a seamless and smooth joint, often used for architectural or decorative purposes. Proper surface preparation and curing time are essential for achieving maximum strength. In summary, the choice of connection type in steel formwork construction depends on factors such as desired strength and rigidity, structure type, reusability, and available resources and expertise. It is crucial to select the appropriate connection type to ensure the safety and stability of the formwork system.

- Q: What are the considerations when selecting the appropriate steel grade for formwork?

- When selecting the appropriate steel grade for formwork, there are several considerations that need to be taken into account. Firstly, the load-bearing capacity of the steel grade is of utmost importance. The steel should be able to withstand the weight and pressure exerted by the concrete and any additional loads that may be applied during construction. It should be able to maintain its structural integrity without any deformation or failure. Secondly, the corrosion resistance of the steel grade is crucial. As formwork is often subjected to moisture and chemicals present in concrete, it is essential to choose a steel grade that can resist corrosion. This will ensure the longevity and durability of the formwork, avoiding any potential safety hazards or costly repairs. Another consideration is the ease of handling and fabrication. The selected steel grade should be easy to cut, shape, and weld, allowing for efficient and accurate construction of formwork. It should also have good dimensional stability, ensuring that the formwork remains in the desired shape and size during use. The cost-effectiveness of the steel grade is also a significant factor. While it may be tempting to opt for a higher grade steel with superior properties, it is essential to evaluate the project requirements and choose a grade that offers the necessary performance at a reasonable cost. This will help to optimize the budget without compromising on the quality and functionality of the formwork. Lastly, compliance with industry standards and regulations should be considered. The selected steel grade should meet the relevant codes and specifications set by governing bodies to ensure that the formwork meets safety standards and can withstand the intended loads and environmental conditions. By taking these considerations into account, one can select an appropriate steel grade for formwork that ensures structural stability, durability, corrosion resistance, ease of handling, cost-effectiveness, and compliance with industry standards.

- Q: How does steel formwork accommodate for different concrete pouring heights?

- Steel formwork can accommodate for different concrete pouring heights by being adjustable and customizable. The formwork panels can be easily adjusted or cut to the required height, allowing for flexibility in creating various concrete pouring levels. Additionally, steel formwork systems often include adjustable accessories such as props or telescopic beams that can be extended or retracted to match the desired pouring height. This adaptability ensures that the steel formwork can effectively accommodate different concrete pouring heights during construction projects.

- Q: How does steel formwork contribute to the quality of the concrete finish?

- Steel formwork plays a crucial role in ensuring the quality of the concrete finish. Firstly, steel formwork provides a strong and rigid framework that holds the concrete in place during the pouring and curing process. This prevents any movement or deformation of the concrete, resulting in a smooth and even finish. Additionally, steel formwork offers better dimensional stability compared to other types of formwork materials. It does not warp or distort under the pressure of the wet concrete, ensuring accurate and consistent shapes and dimensions. This is particularly important for structures that require precise measurements, such as beams, columns, or walls. Moreover, steel formwork allows for better control over the surface finish of the concrete. The smooth and non-absorbent surface of steel minimizes the risk of air bubbles or voids forming on the concrete surface. This results in a visually appealing finish with reduced imperfections. Furthermore, steel formwork provides excellent resistance to moisture and chemicals present in the concrete mix. This prevents the formwork from being damaged or deteriorated, ensuring a clean and unblemished concrete finish. It also allows for easy removal of the formwork once the concrete has cured, without leaving any residues or marks on the surface. Lastly, steel formwork can be reused multiple times, making it a cost-effective and sustainable choice. The ability to reuse the formwork ensures consistent quality in subsequent concrete pours, as the same set of formwork will provide the same level of support and accuracy. This eliminates the need for frequent investments in new formwork materials, reducing overall project costs and environmental impact. In conclusion, steel formwork significantly contributes to the quality of the concrete finish through its strength, dimensional stability, control over surface finish, resistance to moisture and chemicals, and reusability. Its use ensures a smooth, accurate, and visually appealing concrete surface while providing durability and cost-effectiveness to construction projects.

- Q: Is steel formwork suitable for projects with tight deadlines?

- Yes, steel formwork is suitable for projects with tight deadlines. Steel formwork is known for its durability and strength, making it capable of withstanding high pressure and repetitive use. This allows for faster construction as it can be reused multiple times without losing its structural integrity. Additionally, steel formwork is easy to assemble and disassemble, enabling quick and efficient installation and removal. Its versatility and adaptability also make it suitable for a wide range of construction projects, regardless of size or complexity. Therefore, using steel formwork in projects with tight deadlines can help expedite the construction process and meet the project timeline.

- Q: How does steel formwork contribute to the overall safety of the construction process?

- There are several ways in which steel formwork enhances the safety of the construction process. Firstly, its strength and durability allow it to withstand the weight and pressure exerted during construction, reducing the possibility of formwork failure and subsequent accidents or injuries. Moreover, steel formwork is specifically designed to create a stable and secure structure for pouring concrete. Its precise alignment and tight joints prevent any leakage or seepage of concrete, thus minimizing the chances of structural instability or collapse. This ensures the safety of workers and the overall integrity of the building under construction. Furthermore, steel formwork exhibits high resistance to fire and high temperatures. In the unfortunate event of a fire on the construction site, it acts as a fire-resistant barrier, protecting workers and preventing the spread of fire to other areas. Consequently, the risk of fire-related accidents or injuries is greatly reduced, enhancing the overall safety of the construction process. In addition, steel formwork is designed to be reusable, allowing it to be utilized for multiple construction projects. This not only reduces formwork costs but also minimizes waste and environmental impact. By opting for steel formwork, construction companies can promote sustainability and create a safer construction environment by minimizing the need for constant formwork replacement. In conclusion, steel formwork makes a significant contribution to the overall safety of the construction process by providing strength, durability, stability, and fire resistance. Its precise alignment and tight joints ensure the integrity of the structure being built, diminishing the risk of accidents or collapse. Additionally, its reusability supports sustainability efforts and waste reduction. Overall, steel formwork plays a vital role in establishing a safe and secure construction site.

- Q: How does steel formwork compare to plastic formwork in terms of cost and durability?

- In terms of upfront cost, steel formwork is generally pricier than plastic formwork. The cost of steel formwork encompasses material, fabrication, and transportation expenses, which can be higher in comparison to plastic formwork. Conversely, plastic formwork is relatively more affordable due to its lower material and production costs. Nonetheless, when it comes to durability, steel formwork holds a significant advantage. Steel is renowned for its strength and endurance, enabling it to withstand substantial loads and repeated use over time. It is resistant to wear and tear, deformation, and damage caused by external factors such as weather conditions or mishandling. This durability ensures that steel formwork can be reused multiple times, resulting in long-term cost savings. On the other hand, plastic formwork, despite being cost-effective initially, may have limitations in terms of durability. Plastic is not as sturdy as steel and may be susceptible to deformation or cracking, especially under heavy loads or inadequate handling. Although plastic formwork can still be reused multiple times, it may require more frequent replacement or repair in comparison to steel formwork. To summarize, steel formwork may have a higher initial cost but offers superior durability and longevity. Plastic formwork, on the other hand, is cheaper but may not withstand heavy loads or repeated use as effectively as steel. The choice between the two depends on the specific requirements of the project, budget constraints, and the anticipated lifespan of the formwork.

Send your message to us

Tabel-formwork for Formwork and Scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords