Usg Ceiling Grid - Suspension Ceiling Tee Grid Ceiling System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Suspension System Frame for Ceiling Tiles-Ceiling Tee Bar

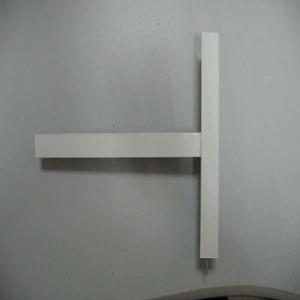

Specification of Suspended Ceiling Grid :

1.There are Flat system, Groove system and Slim system for t grid

2.Four kind of tee make up of a ceiling frame. those are main tee, long cross tee, short cross tee and wall angle

The height normally is 38 or 32, thickness from 0.20-0.40MM

The normal size as belows(pls mainly focus on the lenghth we have):

main tee:38*24*3600mm or 38*24*3660mm

main tee:32*24*3600mm or 32*24*3660mm

long cross tee:26*24*1200mm or 26*24*1210mm

Short cross tee:26*24*600mm or 26*24*610mm

wall angle:24*24*3000mm or 24*24*3050mm

wall angle:21*21*3000mm or 21*21*3050mm

Applications of Suspension Ceiling Grid:

commercial ceiling suspension grid for false ceiling

Package of Suspension Ceiling Grid

1.main tee:30 pcs in one carton

2.long cross tee: 50 pcs in one carton

3.short cross tee:75 pcs in one carton

4.wall angle:50 pcs in one carton

Production Line of suspension ceiling grid

We have 6 production line for ceiling grid, 30 containers per month. our quality undertested by the world market over many years we are your unique relible choice

- Q: Known floor building elevation, ceiling elevation, light steel keel gypsum board ceiling boom length how to calculate?

- You can put the big hanging, expansion screws and hanging bars connected, and then look to know the amount.

- Q: Light steel keel manufacturers is not only the production of light steel keel?

- In addition to our light steel keel will produce paint keel, triangular keel, stone and so on. But small factories are generally only the production of light steel keel.

- Q: Home decoration with wood keel good or light steel keel good

- Specifically to see what kind of top hanging, if it is pvc wood keel of course, if it is gypsum board, of course, light steel keel. Integrated ceiling.

- Q: I now decorate a facade, want to save some money, the original use of light steel gypsum board separated from the good, but not what I want the effect, I would like to use the original material change, and listen to people say that gypsum board movement fragile. Demolished on the bad equipment. The specific situation is that there are two rooms are separated by gypsum board, that is, there are four walls are gypsum board, I would like to change the main are: 1, all the gypsum wall to move the location. 2, which has two walls need to take off a large part of the excess. Would you like to ask my friend to see if my program is feasible? I left this point, all reward

- Gypsum board wall demolition of the large gypsum board can be reused (except for violent demolition), the self-tapping screw unloaded just fine. Light steel keel can also be partially recycled. But you still have to buy some gypsum board and light steel keel, the original those who can not use enough.

- Q: I am looking for the fire resistance of the building components, see the middle of the house wall with "steel keel" and "light steel keel", what is the difference between the two? What do I want to know is that the two are different in terms of function and practical application? What are the advantages and disadvantages?

- Light steel keel is used to ceiling the ceiling, and steel keel is a kind of iron frame, the cost is relatively high, to do the effect of quality than the light steel keel expensive, almost more than light steel keel on your 40%

- Q: What is the difference between light steel keel and aluminum alloy keel?

- Aluminum alloy keel cost is high Guichang keel prices are relatively cheap in almost all with light steel keel

- Q: Light steel keel ceiling models which

- Wall steel ceiling keel specifications and information decoration materials Light steel keel wall materials are 50, 75, 100, 150 and several other Light steel keel thickness ranging from 0.4mm to 2.0mm.

- Q: There is heating the ground, the above to add light steel keel wall how to deal with?

- First find out the ground to the laying of the warm tube, it is best to get to warm construction plans. And then according to the marked on the map, looking away from the far away to scribe, look and design the wall is likely to be compatible, and then bolt, install the keel. It is estimated that not easy to get, to be very careful, before the construction of the warm door off, the water vent and then get.

- Q: 3.5 meters high, 4.2 meters long.

- Each vertical interval of 25 cm each horizontal interval of 40 cm each. With 3.5 / .2 5 get 14. with 4.2 / .4 was 10.5,14 * 11 = 154 so side with 154 nails, both sides is 308.

- Q: I'm wanting to paint 1 Corinthians 13 on our bedroom ceiling in some sort of spiral design. I just want it to be pretty and look professional. I'm weary about doing the spiral design thought because I just don't know how I would get it just right... but I can't think of any other design that would look right.. I think it would look funny just written straight across on the ceiling. Anyone have any ideas or tips on doing this?

- I would sketch it out in pencil first. That way you could erase what does not look good before committing to the design in paint.

Send your message to us

Usg Ceiling Grid - Suspension Ceiling Tee Grid Ceiling System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords