Unistrut Ceiling Grid System - Ceiling Tee Bar System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

Main Product Features:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the

keels' vertical points and intensity.

(4) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..

We can meet your customized demands.

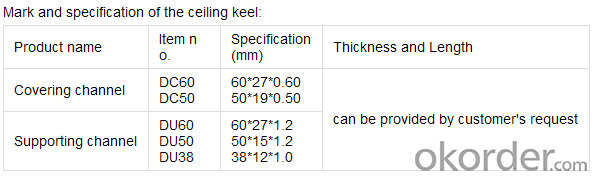

Product Specifications:

Image:

- Q: Introduction of paint keel

- Its role and aluminum keel is the same, but also for the beautiful, from a stent role. With supporting the silicon calcium board and mineral wool board and so on.

- Q: There is a ceiling of light steel keel partition to be how high, whether only need to do ceiling elevation, or to be higher than 20cm, or do the top plate bottom ~

- According to the normal process, it should be done first to do the ceiling wall.

- Q: Offering 800,000$ worth of machinery and patents in collateral. Any suggestions? I am in the construction industry dealing with powder actuated fasteners for the installation of acoustical ceiling grid, panels, electrical fixtures, electrical wiring, data cables etc... I have an extensive 70 page business plan.I also have bad credit.

- Patents do not have value until they are producing money. Nothing worth less than a wild idea with no implementation. Assuming you have machinery, which is worth 800,000 in real present day dollars, not original price, that would justify a loan of 200,000 with that collateral. Primarily because it would take 50% discount just to turn the stuff once you go under. It will take another 25% to take possession, haul to holding, store until sale, ship to buyer. That leaves him with just about what he put into the project. Again that assumes 800k on the actual value. Business plans can be downloaded from the internet fully filled out and seldom reflect actual performance of a business. Chances are good if it takes 70 pages to spell out what the business does, it is too complex for a one man show. Which means obligations for workers and employees. You have bad credit for a reason. That reason usually reflects your financial acumen.

- Q: In the CAD 'light steel keel seal 18 PCT big core board posted 8 PCT car side gray paint glass' What is the meaning of this sentence? Request to say the details of the point yo.

- Light steel dragon skeleton to do 18mm large core board surface paste 8mm gray paint glass

- Q: but i dont know if its safe or not. i cant stand to have to look at that ceiling every night tho. i dont want to cover with fabric i know that much. i was also thinking of wall papering over it. help!!!!!!!

- Is your drop ceiling the type that is replaceable? For example, it uses squares that are suspended below the real ceiling? If so, I don't think covering it with dry wall mud would be a good idea. If you look on-line, you might find a ceiling tile that you like better, so you could replace it. Or, I like your idea of covering it with wall paper. You could get a very unique ceiling and one that you like!

- Q: Mainly check the contents of which piece of people

- Construction side to do the hidden information

- Q: Double-sided 200 light steel keel gypsum board wall how much money a square

- Use 150 light steel keel, double-sided double-layer 12mm gypsum board, do paint, you can reach 200mm specifications.

- Q: Gypsum board ceiling with light steel keel how much material. Roof a total of 90 square feet. In addition to gypsum board, 1 square, how much light steel keel, pay keel, hanging, hanging, the main then, pay, hanging gold and other accessories

- Generally to design drawings construction, it is difficult to say how much, there are many types of keel, the installation method is also a lot of if it is their own decoration, then you can follow the "light steel keel partition, ceiling standard Atlas.pdf" construction

- Q: Light steel keel do hanging cabinet please

- With a strong strength and long-term development goals in the market, the new North Dragon to the rich experience, advanced management concepts with professional service standards together, the quality of materials and systems into the market to improve the quality of life of living.

- Q: Light steel keel gypsum board cut off how much money a square

- Material costs 20-30 yuan / m2, labor costs are not the same as the region, 30-50 yuan / m2 or so.

Send your message to us

Unistrut Ceiling Grid System - Ceiling Tee Bar System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords