304 Stainless Steel Sheet Building metal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

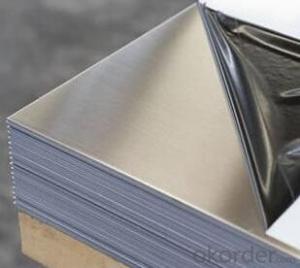

Building metal 304 stainless steel sheet

Item | Building metal 304 stainless steel sheet |

Standard | ASTM,AISI,JIS,EN,DIN,GB |

Surface | 2b ba HL |

Thickness | Cold rolled:0.3mm-3mm Hot rolled:3mm-100mm |

Width | 1000mm/1219mm/1250mm/1500mm/1524mm/2000mm, or as customer’s requires. |

Length | As customer’s requirements. |

Edge | Slit/Mill Edge |

Origin | TISCO,LISCO,JISCO,BAOSTEEL, Eastern Special Steel etc. |

MOQ | 1 Ton |

Price Term | FOB/CFR/CIF |

Delivery | 7-10 days after the deposit |

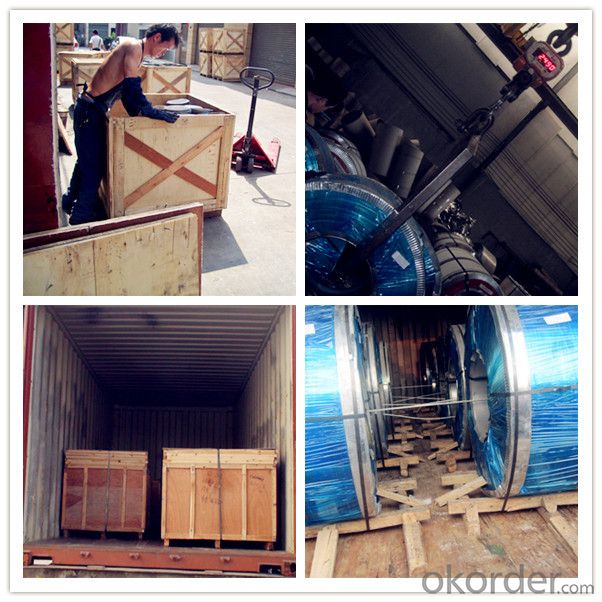

Packaging | Seaworthy Export Standard or as customer's requests. |

Application | construction field;ship building industry;petroleum and chemical industries;war and electricity industries;food processing and medical industry; boiler heat exchanger; machinery and hardware industry |

2B | The surface brightness and flatness of 2B is better than 2D. Then through a special surface treatment to improve its mechanical properties, 2B could nearly satisfy comprehensive uses. |

NO.3 | Polished with abrasive belt of git#100#200,have better brightness with discontinuous coarsestria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

NO.4 | Polished with abrasive belt of grit#150#180,have better brightness with discontinuous coarsestria, but thinner than NO.3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc, |

HL | Polished with abrasive belt of grit#150#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc |

8K | The product have excellent brightness and prefect reflexivity can be the mirror |

More Products

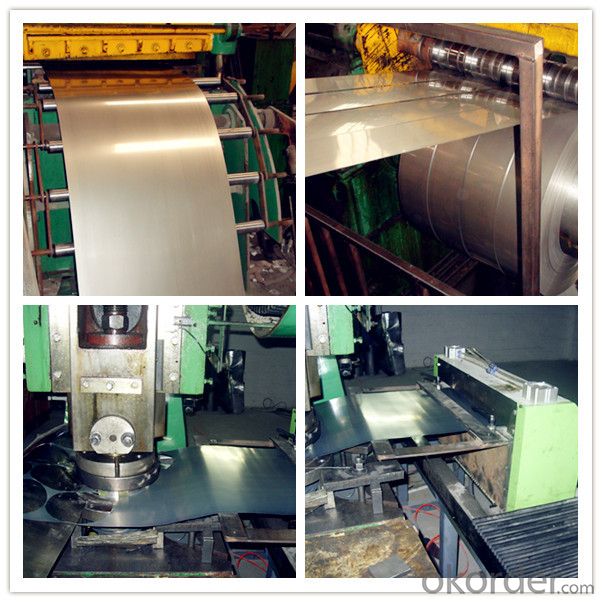

Manufacting

| Q&A corrugated steel sheet | |||||||

| 1 | Q: WHAT ARE YOUR MAIN PRODUCT? | ||||||

| A:We are specializing in providing cold rolled 201/410/430 Stainless Steel Coil / Stainless Steel Strip /Stainless Steel Sheet / Stainless Steel Plate, Stainless Steel Circle, Stainless Steel tube/ Stainless Steel Pipe Sheets. | |||||||

| 2 | Q: WHAT ARE YOUR ADVANTAGES? | ||||||

| 1. We have a strict quality control from production to delivery. 2. We use advanced system and tool to improve working efficiency and control every step. 3. We have a specialized team in dealing with all the documents required by customers. We aim to zero error to save money and time for client. | |||||||

| 3 | Q: CAN I GET FREE SAMPLE? | ||||||

| A: YES. We can provide free sample. But we are not responsible for the delivery fee . | |||||||

Packing & Loading

- Q: Can stainless steel sheets be used in high-temperature environments?

- Yes, stainless steel sheets can be used in high-temperature environments. Stainless steel is known for its excellent heat resistance properties, making it suitable for various applications in high-temperature environments. The specific grade of stainless steel used and its composition determines its maximum operating temperature. Austenitic stainless steels, such as grades 304 and 316, can withstand temperatures up to 1600°F (870°C) without losing their mechanical strength or corrosion resistance. However, higher alloyed stainless steels, such as grades 309 and 310, are specifically designed to handle even higher temperatures, up to around 2100°F (1150°C). These stainless steel sheets are commonly used in industries like power generation, chemical processing, furnace manufacturing, and aerospace, where exposure to extreme heat is a requirement.

- Q: Can stainless steel sheets be used in industrial applications?

- Yes, stainless steel sheets can definitely be used in a wide range of industrial applications. Stainless steel is known for its excellent corrosion resistance, durability, and strength, making it ideal for various industrial environments. It is commonly used in sectors such as automotive, aerospace, construction, manufacturing, food and beverage, chemical processing, and many others. Stainless steel sheets are often used for their ability to withstand high temperatures, harsh chemicals, and extreme conditions. They can be fabricated into different shapes and sizes, making them suitable for a wide range of applications. Stainless steel sheets are commonly used for manufacturing equipment and machinery, storage tanks, pipelines, architectural structures, and as a protective layer on surfaces that require resistance to corrosion. Furthermore, stainless steel sheets offer hygienic properties, making them suitable for applications in the food and beverage industry. They are easy to clean, maintain, and sterilize, ensuring compliance with strict industry standards. In summary, stainless steel sheets are versatile and reliable materials that can be effectively used in various industrial applications due to their exceptional corrosion resistance, durability, strength, and hygienic properties.

- Q: 430 stainless steel plate maximum temperature tolerance is how many degrees?

- 430 stainless steel plate is 430 stainless steel sheet shaped products. 430 stainless steel plate according to the thickness can be divided into thin plate, medium plate, thick plate and other forms; at present the maximum width of up to 2000mm, length is not limited.

- Q: Can stainless steel sheets be used in marine environments?

- Yes, stainless steel sheets can be used in marine environments. Stainless steel is highly resistant to corrosion, making it suitable for marine applications where it will be exposed to saltwater and high humidity. It is commonly used in marine vessels, offshore platforms, and other structures that require durability and resistance to rust and corrosion.

- Q: What are the applications of stainless steel sheets in the automotive industry?

- Due to their advantageous properties, stainless steel sheets are extensively utilized in the automotive industry. These sheets play a vital role in various automobile components, contributing to the overall performance, durability, and aesthetics of vehicles. A key application of stainless steel sheets in the automotive industry is seen in the manufacturing of exhaust systems. With its high resistance to corrosion and heat, stainless steel proves to be an ideal material for exhaust pipes. These sheets can endure the elevated temperatures generated by the engine, ensuring the longevity and reliability of the exhaust system. Furthermore, stainless steel sheets find use in the production of automotive body panels. They offer exceptional strength and rigidity, enabling the creation of lightweight yet robust body parts. The corrosion resistance of stainless steel is also advantageous, as it guarantees the long-lasting quality of the body panels, even in harsh weather conditions. Moreover, stainless steel sheets are employed in the fabrication of fuel tanks and other fluid storage components. The corrosion resistance and ability to withstand high pressure make stainless steel a suitable material for such applications. The integration of stainless steel in fuel tanks ensures their leak-free and durable nature, ultimately enhancing safety and longevity. Additionally, stainless steel sheets are utilized in the manufacture of various interior and exterior trim parts. These include decorative elements like grilles, trims, and accents, which enhance the vehicle's aesthetics. The ability of stainless steel to be polished and finished to a high shine adds an element of elegance and sophistication to the car's design. To summarize, stainless steel sheets have multiple applications within the automotive industry. They are utilized in exhaust systems, body panels, fuel tanks, and trim parts, among others. The exceptional properties of stainless steel, including corrosion resistance, heat resistance, and strength, greatly contribute to the overall performance, durability, and aesthetics of automobiles.

- Q: How do you prevent scratches or dents on stainless steel sheets?

- There are several measures that can be taken to avoid scratches or dents on stainless steel sheets: 1. Exercise caution when handling: Take care not to drop or drag stainless steel sheets against rough surfaces. It is advisable to wear gloves or protective gear to minimize the risk of scratches caused by sharp objects or tools. 2. Opt for gentle cleaning materials: To prevent scratches when cleaning, use soft cloths or non-abrasive sponges. Avoid steel wool or harsh cleaning agents that can harm the surface. Also, make sure to wipe in the direction of the grain to preserve the stainless steel's appearance. 3. Apply protective films or sheets: Adding a protective film or sheet to the stainless steel surface can provide an extra layer of defense against scratches or dents. These films are typically adhesive and can be easily removed once the stainless steel sheets are installed. 4. Store correctly: Store stainless steel sheets in a clean and dry environment to prevent scratches or dents caused by contact with other objects. Avoid stacking sheets directly on top of each other without any protective barrier in between. 5. Invest in edge protectors: Stainless steel sheets are often susceptible to dents or scratches on their edges. Using edge protectors or corner guards can help prevent damage during handling, transportation, or storage. By adhering to these preventive measures, the likelihood of scratches or dents on stainless steel sheets can be significantly reduced. This will ensure their durability and preserve their flawless appearance.

- Q: How do stainless steel sheets compare to other materials like aluminum or carbon steel?

- Stainless steel sheets have several advantages over other materials such as aluminum or carbon steel. Firstly, stainless steel is highly resistant to corrosion, making it suitable for applications in harsh environments or exposure to moisture. In contrast, aluminum is more prone to corrosion, while carbon steel requires additional protective coatings to prevent rusting. Moreover, stainless steel sheets offer superior strength and durability compared to aluminum, making them suitable for heavy-duty applications. Carbon steel may have similar strength properties, but it is more susceptible to corrosion and requires regular maintenance. Additionally, stainless steel sheets provide excellent heat resistance, making them ideal for high-temperature applications that aluminum may not withstand. Carbon steel can handle high temperatures, but it may be prone to oxidation if not properly protected. Lastly, stainless steel sheets have an aesthetically pleasing appearance and are available in various finishes, making them more suitable for architectural and decorative purposes compared to aluminum or carbon steel. Overall, stainless steel sheets offer a combination of corrosion resistance, strength, durability, heat resistance, and aesthetic appeal that sets them apart from other materials like aluminum or carbon steel.

- Q: Can stainless steel sheets be used for electrical or electronic applications?

- Yes, stainless steel sheets can be used for electrical or electronic applications. Stainless steel has excellent electrical conductivity and is resistant to corrosion, making it an ideal material for various electrical components. It is commonly used in electrical enclosures, switchgear, control panels, and other electrical equipment. Additionally, stainless steel sheets can be fabricated into different shapes and sizes, making them suitable for various electronic applications such as printed circuit boards (PCBs), connectors, and terminals. The durability and high temperature resistance of stainless steel also make it a preferred choice for electrical and electronic applications in harsh environments.

- Q: Is there a big price difference between the SUS304 stainless steel plate and the drawing plate?

- The ordinary 304 stainless steel plate and the processed 304 drawing stainless steel plate, the price difference is not very big. You can consult the specific price.

- Q: What's the difference between 201 and 204 stainless steel plates? Thank you

- Different components: the main difference in nickel containing impurities, 201 such products performance 04 corrosion resistance, stamping performance far better than the 01, the 04 is generally used in complex environment, need strong resistance to corrosion for 01 place, environmental requirements are not very high, or the stainless steel demand is not high place

Send your message to us

304 Stainless Steel Sheet Building metal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords