Sublimation Aluminum Sheets for Trailer Tool Case - Aluminum Embossed Panel Atlanta GA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Embossed Panel for Trailer Tool Case

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Aluminum Embossed Panel for Trailer Tool Case

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Embossed Panel for Trailer Tool Case

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

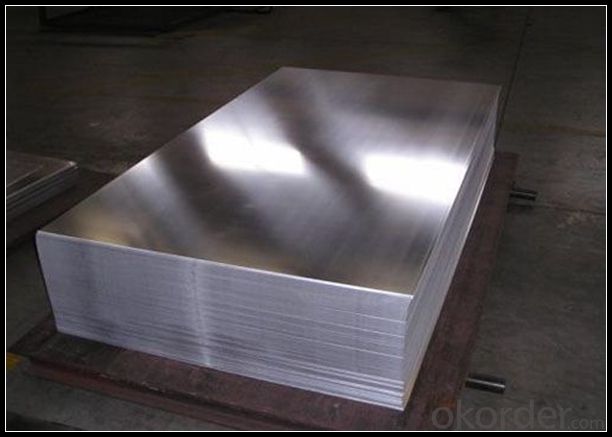

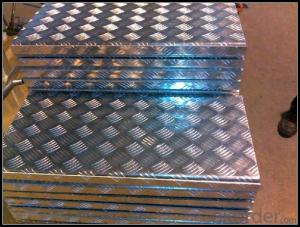

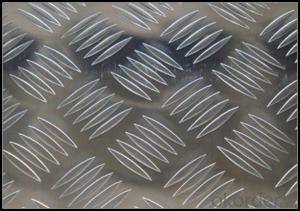

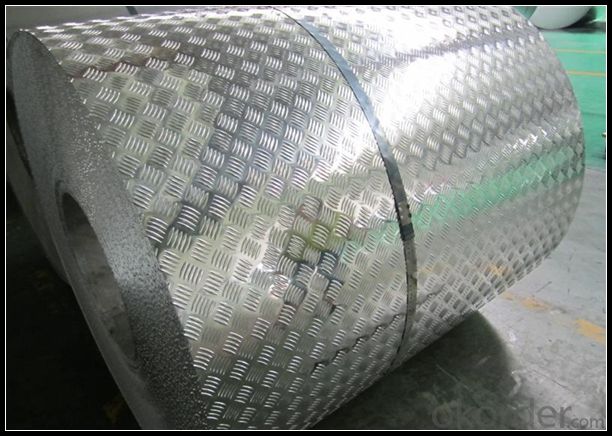

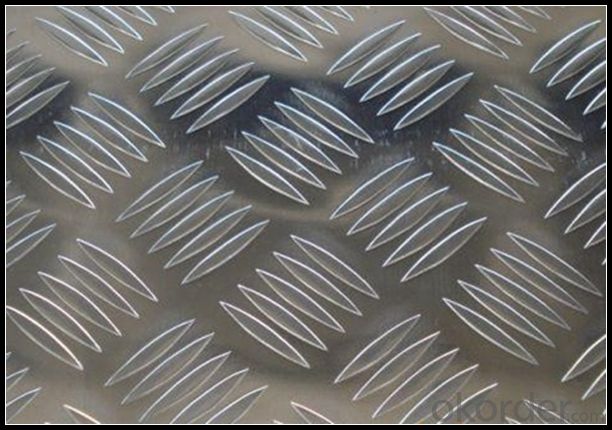

5. Image of Aluminum Embossed Panel for Trailer Tool Case

6. Package and shipping of Aluminum Embossed Panel for Trailer Tool Case

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How to distinguish aluminum sheet from magnesium sheet?

- put two sheets into excess NaOH. The one that reacts with NaOH, generating sediment, is magnesium sheet,(sediment, but Al(OH)3 is amphoteric:Mg(OH)2) another one without sediment is aluminum sheet(in fact, there is sediment Al(OH)3, but it will react with alkali,)

- Q: What are the standard sizes of aluminum sheets?

- The standard sizes of aluminum sheets can vary depending on the manufacturer and specific requirements. However, some commonly available standard sizes for aluminum sheets include 4 feet by 8 feet (1.2 meters by 2.4 meters), 4 feet by 10 feet (1.2 meters by 3 meters), and 5 feet by 10 feet (1.5 meters by 3 meters). These sizes are widely used in various industries and are readily available in the market. Additionally, custom sizes can also be obtained through specialized aluminum sheet suppliers to meet specific project needs.

- Q: How do aluminum sheets perform in terms of wear resistance?

- Aluminum sheets generally offer good wear resistance due to their inherent properties and surface characteristics. Aluminum is a lightweight yet durable material that exhibits a high strength-to-weight ratio, making it suitable for various applications where wear resistance is required. The wear resistance of aluminum sheets can be further enhanced through various methods such as alloying, heat treatment, and surface treatments. Alloying elements like copper, magnesium, or zinc can be added to aluminum to improve its hardness and wear resistance. Heat treatment processes like precipitation hardening can also increase the strength and wear resistance of aluminum sheets. Furthermore, surface treatments such as anodizing or applying protective coatings can significantly enhance the wear resistance of aluminum sheets. Anodizing forms a protective oxide layer on the surface of aluminum, providing increased resistance to abrasion, corrosion, and wear. Coatings like powder coatings or paint can also provide an additional layer of protection against wear and tear. In terms of specific applications, aluminum sheets are commonly used in industries such as automotive, aerospace, construction, and marine due to their excellent wear resistance. They are utilized in components that experience sliding, rubbing, or impact, such as panels, body parts, and structural elements. Overall, while aluminum sheets may not possess the same level of wear resistance as certain steel alloys or other specialized materials, they offer a good balance between strength, weight, and wear resistance. With appropriate alloying, heat treatment, and surface treatments, aluminum sheets can provide satisfactory wear resistance in a wide range of applications.

- Q: Are the aluminum sheets suitable for manufacturing architectural wall panels?

- Yes, aluminum sheets are suitable for manufacturing architectural wall panels. Aluminum is a versatile and popular material in the construction industry due to its numerous benefits. Firstly, aluminum is lightweight, making it easy to handle and install. This is especially advantageous for architectural wall panels, as it reduces the overall weight of the structure, simplifies transportation, and allows for greater flexibility in design. Additionally, aluminum offers exceptional durability and resistance to corrosion. This is crucial for wall panels, as they are exposed to various environmental elements such as rain, UV rays, and temperature changes. Aluminum's natural oxide layer provides a protective barrier, ensuring that the panels remain intact and maintain their appearance over time. Aluminum also provides excellent thermal and acoustic insulation properties. Architectural wall panels made from aluminum can help regulate the internal temperature of buildings, leading to energy savings and improved comfort for occupants. Moreover, aluminum panels help reduce noise transmission, contributing to a quieter indoor environment. Furthermore, aluminum is highly customizable in terms of shape, size, color, and finish. This allows architects and designers to create unique and visually appealing wall panel systems that complement the overall aesthetics of a building. The versatility of aluminum sheets also facilitates the integration of other materials, such as glass or stone, for added design possibilities. Lastly, aluminum is a sustainable material. It is 100% recyclable, and the energy required for recycling aluminum is significantly lower compared to the production of primary aluminum. Choosing aluminum sheets for architectural wall panels aligns with environmentally friendly practices and contributes to the reduction of carbon emissions. Overall, the characteristics of aluminum, including its lightweight nature, durability, resistance to corrosion, thermal and acoustic insulation properties, design flexibility, and sustainability, make it highly suitable for manufacturing architectural wall panels.

- Q: Can aluminum sheets be used for heat dissipation?

- Yes, aluminum sheets can be used for heat dissipation due to their high thermal conductivity.

- Q: What are the different methods of surface protection for outdoor aluminum sheet?

- To ensure the durability and longevity of outdoor aluminum sheets, there are several methods available for surface protection. These methods offer varying advantages and limitations, and the choice should be based on factors such as durability, appearance, cost, and maintenance requirements. One common method is anodizing, which creates a protective oxide layer on the surface. This increases resistance to corrosion, abrasion, and UV rays, while also providing a range of colors and finishes. Another option is powder coating, where a dry powder is applied to the aluminum sheet and baked to create a hard, protective coating. This method offers excellent resistance to weathering, corrosion, and chemicals, and is available in various colors and finishes. Paint coating is another effective method, creating a barrier between the aluminum surface and the environment to prevent corrosion while enhancing aesthetics. It is important to use high-quality paint specifically designed for aluminum to ensure proper adhesion and durability. For those looking to protect the natural appearance of aluminum, clear coating is an option. It provides a layer of protection against corrosion, oxidation, and UV rays and is often applied after anodizing or polishing. Laminating involves adhering a protective film or sheet onto the aluminum surface, offering excellent resistance to scratches, abrasion, and UV rays. This method is commonly used in applications with heavy wear and tear. Chemical conversion coatings, such as chromate conversion coating or phosphating, can be used to improve the corrosion resistance of aluminum sheets. These coatings chemically react with the surface to create a protective layer that inhibits corrosion. When choosing a method of surface protection, it is crucial to consider specific requirements and environmental conditions. Each method has its own advantages and limitations, so careful consideration is needed to ensure the best choice for the aluminum sheet's needs.

- Q: I need help with this question for a report i'm doing, it's about recycling aluminium, please could you give me some reasons why to recycle aluminium and eg.saves energy, and how it does eg. saves energy by...Thanks a lot this will help me loads.P.S this is just a report for my science project.

- Well aluminium is a common metal and throwing it away fills up land fills. Recycling the metal means less mining and ripping up the earth.

- Q: Are aluminum sheets suitable for architectural applications?

- Yes, aluminum sheets are suitable for architectural applications. Aluminum is a versatile material that offers numerous advantages for architectural projects. It is lightweight, yet strong, making it easy to handle and install. Its corrosion-resistant properties make it well-suited for outdoor applications where it is exposed to the elements. Aluminum sheets can be easily formed into various shapes and sizes, allowing for creative and innovative architectural designs. They can be used for cladding, roofing, facades, and interior applications such as ceilings, partitions, and decorative elements. Additionally, aluminum sheets are available in a wide range of finishes, including anodized, painted, or coated, providing architects with the freedom to choose the desired aesthetic for their projects. These finishes can enhance the durability and color retention of the material, ensuring long-term performance and minimal maintenance requirements. Moreover, aluminum is a sustainable material as it is fully recyclable and has a low carbon footprint compared to other metals. This aligns with the increasing focus on environmentally-friendly construction practices in the architectural industry. In summary, aluminum sheets are highly suitable for architectural applications due to their lightweight, strength, corrosion resistance, versatility, range of finishes, and sustainable attributes. Architects can confidently choose aluminum sheets to create visually appealing and durable structures.

- Q: Can the aluminum sheets be used for manufacturing door frames?

- Indeed, door frames can be manufactured using aluminum sheets. Aluminum, a versatile material, finds extensive usage in the construction field owing to its robustness, longevity, and lightweight nature. It can be conveniently molded, curved, and joined through welding processes to fashion door frames of diverse dimensions and styles. Furthermore, aluminum possesses exceptional resistance against corrosion, rendering it suitable for both indoor and outdoor applications. In conclusion, employing aluminum sheets for the production of door frames represents a sensible and widely favored option within the construction sector.

- Q: Can aluminum sheets be used for kitchen backsplashes?

- Yes, aluminum sheets can be used for kitchen backsplashes. Aluminum is a durable and lightweight material that is resistant to moisture and stains, making it a suitable choice for kitchen backsplashes. Additionally, aluminum sheets are easy to clean and maintain, making them a practical option for any kitchen.

Send your message to us

Sublimation Aluminum Sheets for Trailer Tool Case - Aluminum Embossed Panel Atlanta GA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords