Commercial Aluminum Baking Sheets Embossed Panel for Auto Tool Case

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Embossed Panel Aluminum for Making Auto Tool Case

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Embossed Panel Aluminum for Making Auto Tool Case

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Embossed Panel Aluminum for Making Auto Tool Case

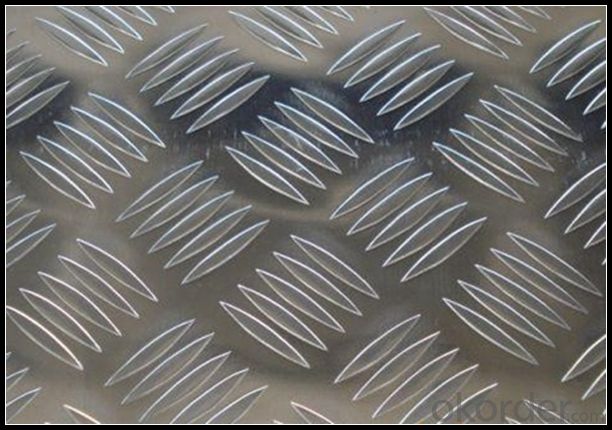

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

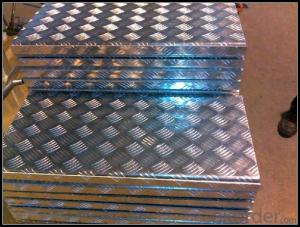

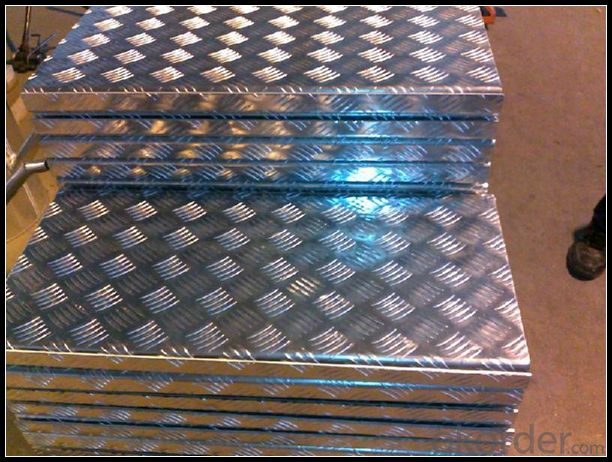

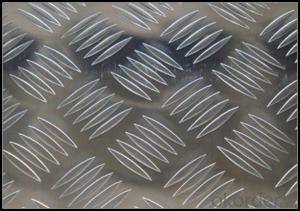

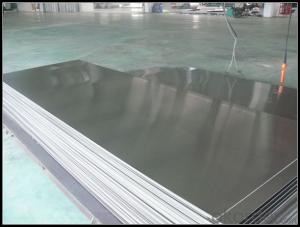

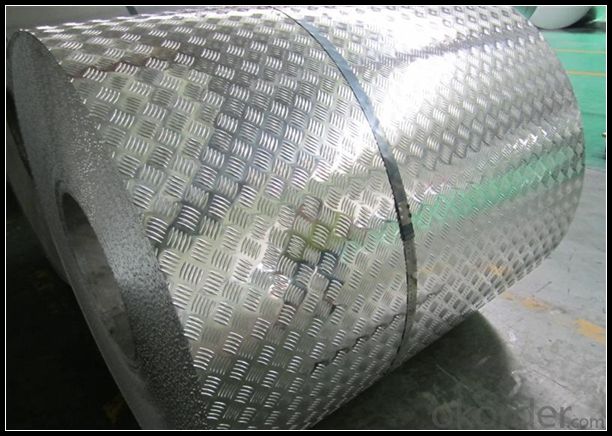

5. Image of Embossed Panel Aluminum for Making Auto Tool Case

6. Package and shipping of Embossed Panel Aluminum for Making Auto Tool Case

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the potential health risks associated with handling aluminum sheets?

- <p>Working with aluminum sheets can pose certain health concerns, primarily due to inhalation of aluminum dust or fumes. Long-term exposure may lead to respiratory issues and potentially neurological problems. Aluminum dust can cause irritation to the eyes, nose, and throat. In some cases, it may contribute to the development of Alzheimer's disease, although this link is still debated. It's important to follow safety guidelines, such as using proper ventilation and wearing protective gear like masks and gloves, to minimize these risks.</p>

- Q: Are aluminum sheets suitable for electrical conductors?

- Aluminum sheets are indeed suitable for electrical conductors. They are frequently employed as conductors in a variety of electrical applications due to their remarkable conductivity, lightweight nature, and relatively low cost in comparison to metals such as copper. With approximately 61% of copper's conductivity, aluminum serves as an efficient conductor for most electrical purposes. Power transmission lines, electrical wiring, bus bars, and numerous other electrical components commonly utilize aluminum sheets. However, it is crucial to acknowledge that aluminum possesses higher resistance than copper, necessitating larger cross-sections to carry the same current. Additionally, caution must be exercised to prevent overheating when employing aluminum sheets as electrical conductors, as they have a lower melting point than copper.

- Q: How do aluminum plates drill?

- There are many drilling equipment for aluminium sheets,First, the engraving machine can be big or small, and can shape strange.Can also be a self tapping screw drill, which can drill.

- Q: Can the aluminum sheets be used for manufacturing electrical connectors?

- Yes, aluminum sheets can be used for manufacturing electrical connectors. Aluminum is a lightweight and highly conductive metal, making it suitable for transferring electricity. It is often used in various electrical applications, including connectors, due to its excellent conductivity and corrosion resistance. Additionally, aluminum can be easily shaped and formed into different connector designs, making it a versatile material for manufacturing electrical connectors.

- Q: How are aluminum sheets cleaned and maintained?

- Aluminum sheets can be effectively cleaned and maintained with a few simple steps. To begin, it is important to remove any loose dirt or debris from the surface of the sheets. This can be done by using a soft brush or cloth to gently sweep away the particles. Next, a mild detergent solution can be prepared by mixing a small amount of dish soap or a specialized aluminum cleaner with warm water. This solution should be applied to the sheets using a soft sponge or cloth. It is important to avoid using abrasive materials or cleaners that contain harsh chemicals, as these can cause damage to the aluminum surface. After applying the detergent solution, the sheets should be thoroughly rinsed with clean water to remove any residue. It is important to ensure that all soap or cleaner is completely removed, as any remaining residue can lead to staining or discoloration over time. Once the sheets are clean, they should be dried using a clean, soft cloth or towel. This will help to prevent water spots or streaks from forming on the surface. It is important to avoid using abrasive materials or rubbing too vigorously, as this can scratch the aluminum. In terms of maintenance, it is recommended to regularly inspect the aluminum sheets for any signs of damage or corrosion. If any areas are found to be damaged, they should be repaired or replaced as soon as possible to prevent further deterioration. Additionally, it is beneficial to apply a protective coating to the aluminum sheets. This can be done using a specialized aluminum sealant or a clear lacquer. This coating will help to protect the surface from environmental factors such as moisture, sunlight, and pollutants. Overall, cleaning and maintaining aluminum sheets involves regular gentle cleaning with a mild detergent solution, thorough rinsing, and drying with a soft cloth. Additionally, inspecting for damage and applying a protective coating can help to prolong the lifespan and appearance of the sheets.

- Q: I may use the copper or brass for an inlay on a decorative piece of aluminum I'm working on.....

- This Site Might Help You. RE: which has the lower melting temperature....aluminum, copper, or brass...can you list all 3? I may use the copper or brass for an inlay on a decorative piece of aluminum I'm working on.....

- Q: Are the aluminum sheets suitable for manufacturing solar reflectors?

- Yes, aluminum sheets are suitable for manufacturing solar reflectors due to their high reflectivity, lightweight nature, and durability in outdoor conditions.

- Q: What is the standard size of an aluminum sheet?

- The standard size of an aluminum sheet can vary depending on the specific application and industry. However, in general, aluminum sheets are commonly available in standard sizes of 4 feet by 8 feet or 48 inches by 96 inches. These dimensions are widely used in construction, manufacturing, and other industries due to their versatility and compatibility with standard equipment and processes. However, it's important to note that aluminum sheets can also be custom cut or ordered in different sizes to meet specific project requirements.

- Q: Are aluminum sheets conductive?

- Yes, aluminum sheets are conductive.

- Q: Are aluminum sheets suitable for electronic enclosures?

- Yes, aluminum sheets are suitable for electronic enclosures. Aluminum is a lightweight and durable material that offers excellent conductivity and thermal management properties, making it ideal for electronic enclosures. It also provides good shielding against electromagnetic interference (EMI) and offers corrosion resistance, making it a popular choice in the electronics industry.

Send your message to us

Commercial Aluminum Baking Sheets Embossed Panel for Auto Tool Case

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords