Aluminum Flat Sheets Embossed Panel for Truck Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Embossed Panel for Making Truck Tool Box

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Aluminum Embossed Panel for Making Truck Tool Box

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Embossed Panel for Making Truck Tool Box

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

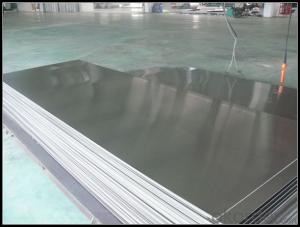

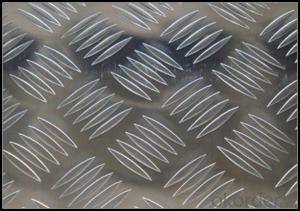

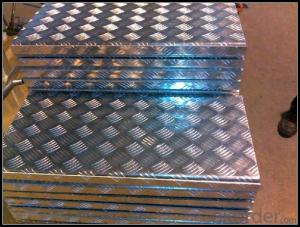

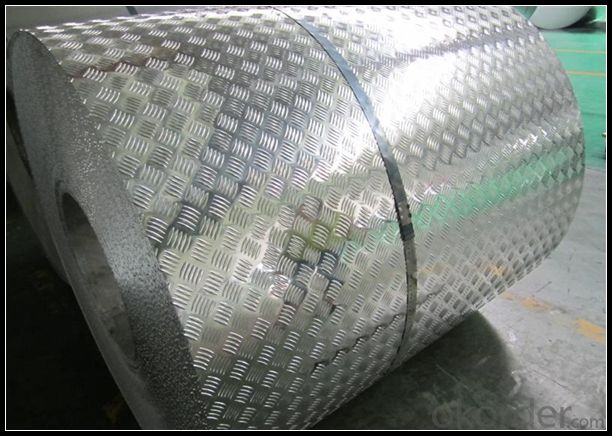

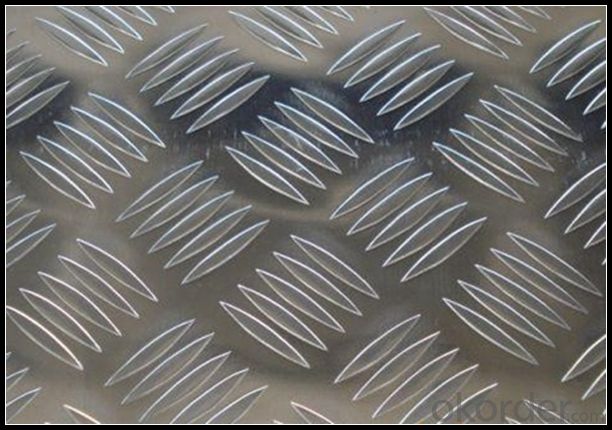

5. Image of Aluminum Embossed Panel for Making Truck Tool Box

6. Package and shipping of Aluminum Embossed Panel for Making Truck Tool Box

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for the cost of an aluminum sheet.

- <p>The cost of aluminum sheets can vary significantly based on factors such as thickness, grade, surface finish, and market conditions. As of my last update, the price range for aluminum sheets could be anywhere from $0.50 to $5 per pound, but this is subject to change. For the most accurate and current pricing, it's best to check with suppliers or on metal exchange platforms, as prices can fluctuate daily. Always consider the specific requirements of your project to determine the exact type and grade of aluminum needed, which will also affect the cost.</p>

- Q: Can aluminum sheets be custom cut to specific sizes?

- Yes, aluminum sheets can be custom cut to specific sizes according to the requirements of the project or application.

- Q: What are the dimensions of standard aluminum sheets?

- Aluminum sheets usually measure 4 feet by 8 feet as a standard. Nevertheless, it is essential to acknowledge the availability of aluminum sheets in diverse thicknesses, spanning from thin gauge sheets to thicker plates. The thickness of standard aluminum sheets can fluctuate from 0.025 inches to 0.25 inches or even greater. Moreover, aluminum sheets can be tailored and adjusted to distinct sizes and shapes according to specific project prerequisites.

- Q: Can aluminum sheets be used for automotive body panels?

- Yes, aluminum sheets can be used for automotive body panels. In fact, aluminum is increasingly being used in the automotive industry for its lightweight properties and high strength-to-weight ratio. Using aluminum sheets for body panels helps reduce the overall weight of the vehicle, which in turn improves fuel efficiency and performance. Additionally, aluminum is highly resistant to corrosion, making it a durable choice for automotive applications. The use of aluminum sheets for automotive body panels has become especially popular in the production of electric vehicles, as their lightweight construction helps maximize the range of the vehicle.

- Q: Are aluminum sheets resistant to staining?

- Yes, aluminum sheets are generally resistant to staining due to their natural ability to form a protective oxide layer on the surface, which prevents corrosion and staining.

- Q: This question asks about the energy savings achieved by using aluminum sheets in comparison to other materials.

- <p>The energy savings achieved by using aluminum sheets instead of other materials can be significant. Aluminum is lightweight and has excellent thermal conductivity, which means it can reduce energy consumption in applications like building insulation and heat exchangers. For instance, aluminum-framed buildings can save up to 40% more energy than those made with traditional materials due to better insulation properties. Additionally, in industrial processes, aluminum's high thermal conductivity can lead to energy savings of around 33% compared to using copper in heat exchangers. The exact amount of energy saved depends on the specific application and the materials being replaced.</p>

- Q: Why does the glue of the aluminium curtain wall glue bubble? At the same time, do not bubble on the side glass, what is the reason?

- When the air injection in silicone sealant generally refer to the site to complete the injection work, poor working conditions. The workers stood above the tripod glue injection, the uniformity of rubber injection is not easy to master, which is easy to glue in air. After sizing glue scraping the surface pressure, trimming smooth, adhesive seam inside the pad bar are mostly made of polyethylene foam obturator rods in the air inside the glue is not easy to overflow, glue dressing compressed air, will produce tension long outward, sealant seam is generally wide, small thickness, arch high displacement ability of weather resistant glue, hardness is low, no pre curing glue is very soft, compressed air pressure to hold long glue slowly bubbling. This phenomenon is more likely to occur on the application of weather resistant adhesive capable of lifting the arch + 25% or more adhesive displacement. Conversely, some weather resistant adhesives that allow less displacement are higher in hardness and thicker before the gel is solidified.

- Q: which is the best bonding method for aluminum sheet and plastic?

- smear glue, there is a glue special for the bonding of plastic and steel materials.

- Q: Aluminum wiring can be a fire hazard because it can oxidize, or combine with oxygen..

- Well, aluminum oxide is Al2O3, right? So for every 2 aluminum atoms there are 3 oxygen atoms, So, if you have three moles of aluminum, you'll need 4 and a half moles of oxygen to react completely with the aluminum. One mole of oxygen atoms weighs 16 grams, so 4.5 moles weighs 72 grams, right? Now it could be that your teacher told you three point zero zero moles of aluminum to get you to use two significant figures, so if you've studied significant figures you may want to look up a more accurate number for the atomic weight of aluminum, and carry the calculation through to three significant figures. Otherwise, 72 is a fine answer.

- Q: why does the bubble apear a few minutes later after putting aluminum sheet into diluted hydrochloric acid?

- Aluminum element is extremely activated and will react with oxygen, generating aluminum oxide, once being exposed in air, so there is a layer of aluminum oxide on the surface of daily aluminum products including aluminum sheet. When aluminum sheet is put into diluted hydrochloric acid, aluminum oxide on the surface will firstly react with hydrochloric acid, generating aluminium chloride and water, the process won’t generate bubble, but after finishing the reaction of aluminum oxide on the surface, when the exposed aluminum element reacts with hydrochloric acid, generating aluminium chloride and oxygen, the bubble appears.

Send your message to us

Aluminum Flat Sheets Embossed Panel for Truck Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords