Colored Aluminum Foil Sheets for Embossed Truck Tool Case Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Embossed Panel for Making Truck Tool Case

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Aluminum Embossed Panel for Making Truck Tool Case

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Embossed Panel for Making Truck Tool Case

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

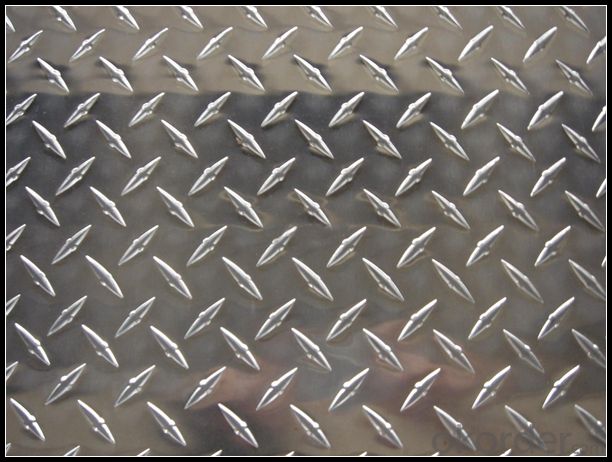

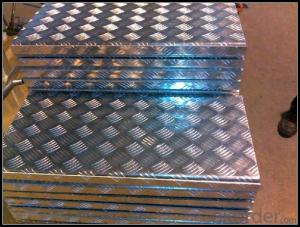

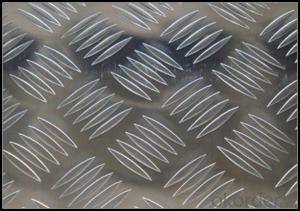

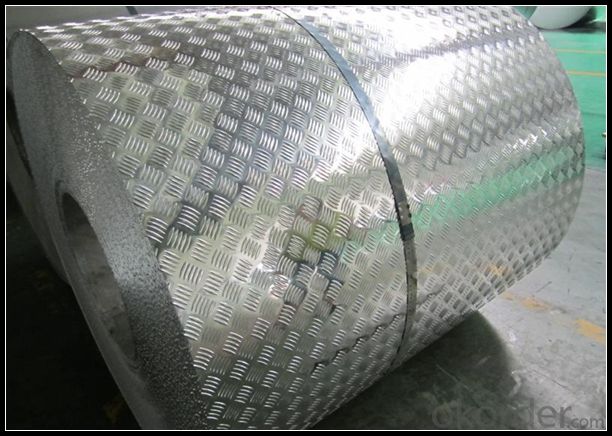

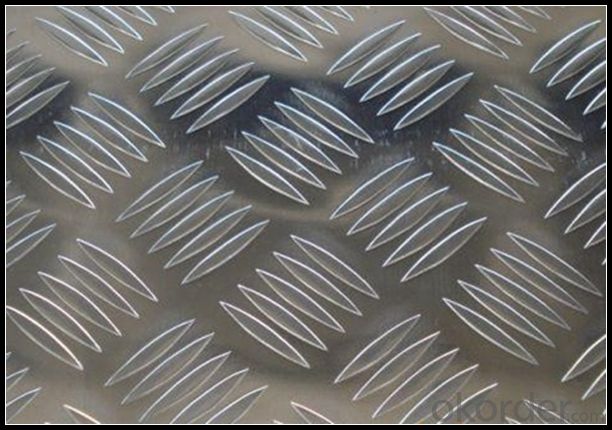

5. Image of Aluminum Embossed Panel for Making Truck Tool Case

6. Package and shipping of Aluminum Embossed Panel for Making Truck Tool Case

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Q. Calculate the number of aluminium ions present in 0.051 g of aluminium oxide.( Hint: The mass of an ion is the same as that of an atom of the same element. Atomic mass of Al = 27 u) Please Explain each and every step!!!Thankx..A lot !!

- The formula for aluminium oxide is Al2O3 Its molecular weight is 2*27+3*16= 54+48 =102 Now, 102g of Al2O3 contains 2*6.023*10^23 number of Al ions so 1g contains (2*6.023*10^23)/102 number of Al ions so 0.051g Al2O3 contain (2*6.023*10^23)/102 *0.051 number of Al ions which is equal to 6.023*10^23*10^-3 = 6.023*10^20 number of Al ions(Answer)

- Q: Are the aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction due to their excellent corrosion resistance, high strength-to-weight ratio, and durability in harsh marine environments.

- Q: This question asks for precautions or methods to protect aluminum sheets from damage during the installation process.

- <p>To ensure that the installation process does not damage aluminum sheets, follow these steps: Use protective gloves to avoid scratches from hand oils or dirt. Employ non-marring tools to prevent any indentations or marks. Handle the sheets carefully to avoid bending or denting. Keep the surface clean and dry to prevent any chemical reactions or stains. Use appropriate support structures to distribute weight evenly and prevent warping. Always follow the manufacturer's guidelines for installation to avoid any improper handling that could lead to damage. Regularly inspect the sheets for any signs of damage during the installation process and address any issues promptly.</p>

- Q: what’s the difference of activated aluminum and aluminum sheet?

- 39,the thermal treatment of age hardening aluminum alloy, 40, lanthanum-praseodymium-cerium aluminum alloy and its producing technology, 41,casting method of cool room pack alloy without draft angle, 42, use the anti-corrosion alloy layer to protect the surface of nickel base alloy products, 43,saltless and inoxidizability remelting method of aluminum, aluminum alloy and aluminum waste...

- Q: Are 101 aluminum sheets suitable for cryogenic applications?

- No, 101 aluminum sheets are not suitable for cryogenic applications.

- Q: What the glue of L solidified aluminum and fast acrylic plate, solid glue?

- Aluminum and acrylic adhesive, if you want to achieve high strength without any effect, can be bonded with KD-5603 trace glue, but this should be with the help of UV curing light curing, if there is no UV curing light, the sun is strong weather, stick in the sun after 30 minutes can be the bonding effect of glass panel; the specific effects can refer to the general glass coffee table with four Aluminum Alloy column, don't see any traces of adhesive;If you only need sticky sticks and low marks, you can choose N-906AB glue or KD-855 quick drying metal glue

- Q: Can aluminum be either conductive or magnitized?

- Aluminium saucepans and frypans demonstrate that Al conducts heat, aluminium wires are used because it is a very good conductor of electricity, but lighter and cheaper than copper, so used on overhead cables. Most lay-people would describe Al as non-magnetic. However, Al is weakly paramagnetic. It does not hold a magnetic field, but does respond to a (strong) magnetic field, albeit weakly. The effect is strongest at low temperatures, and decreases as temp increases.

- Q: Can aluminum sheets be easily shaped or bent into desired forms?

- Aluminum sheets possess the advantageous characteristic of being effortlessly malleable, allowing them to be shaped or bent into desired configurations. This high malleability of aluminum ensures that it can be easily manipulated without any risk of fracturing or breaking. Moreover, its low density and impressive strength-to-weight ratio deem it an optimal selection for numerous applications that necessitate shaping or bending. Various techniques, including press-braking, roll-forming, or utilization of specialized tools like a sheet metal brake, can be employed to shape or bend aluminum sheets. The simplicity associated with shaping or bending aluminum sheets has propelled its widespread adoption in industries such as automotive, aerospace, construction, and manufacturing, where customized forms and designs are frequently required.

- Q: What are the different types of surface treatments available for marine-grade aluminum sheets?

- There are several types of surface treatments available for marine-grade aluminum sheets, including anodizing, powder coating, and painting. Anodizing involves creating a protective oxide layer on the surface of the aluminum, which enhances its corrosion resistance. Powder coating involves applying a dry powder to the surface, which is then heated to form a durable and protective coating. Painting is another option, where a layer of paint is applied to the aluminum surface to provide both aesthetic appeal and protection against corrosion.

- Q: This question asks if aluminum sheets are suitable for outdoor use in environments with high temperatures.

- <p>Yes, aluminum sheets can be used for outdoor applications even in high temperatures. Aluminum has a high melting point of around 660掳C (1220掳F), making it resistant to heat. It also has good thermal conductivity, which allows it to dissipate heat quickly. However, it's important to note that prolonged exposure to high temperatures can cause aluminum to expand and potentially warp. For outdoor applications, especially in high-temperature environments, it's recommended to use aluminum alloys designed for such conditions to ensure durability and performance.</p>

Send your message to us

Colored Aluminum Foil Sheets for Embossed Truck Tool Case Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords