Aluminum Mesh Filter Sheets - AA1060 Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets AA1060 Used for Construction Description

Aluminum Sheets AA1060 Used for Construction is cut from aluminum coils 1xxx. The aluminum content of Aluminum Sheets AA1060 Used for Construction is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets AA1060 Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Sheets AA1060 Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

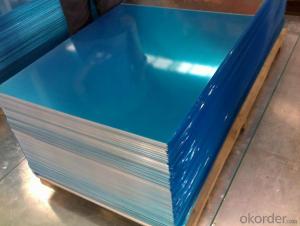

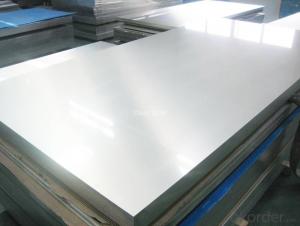

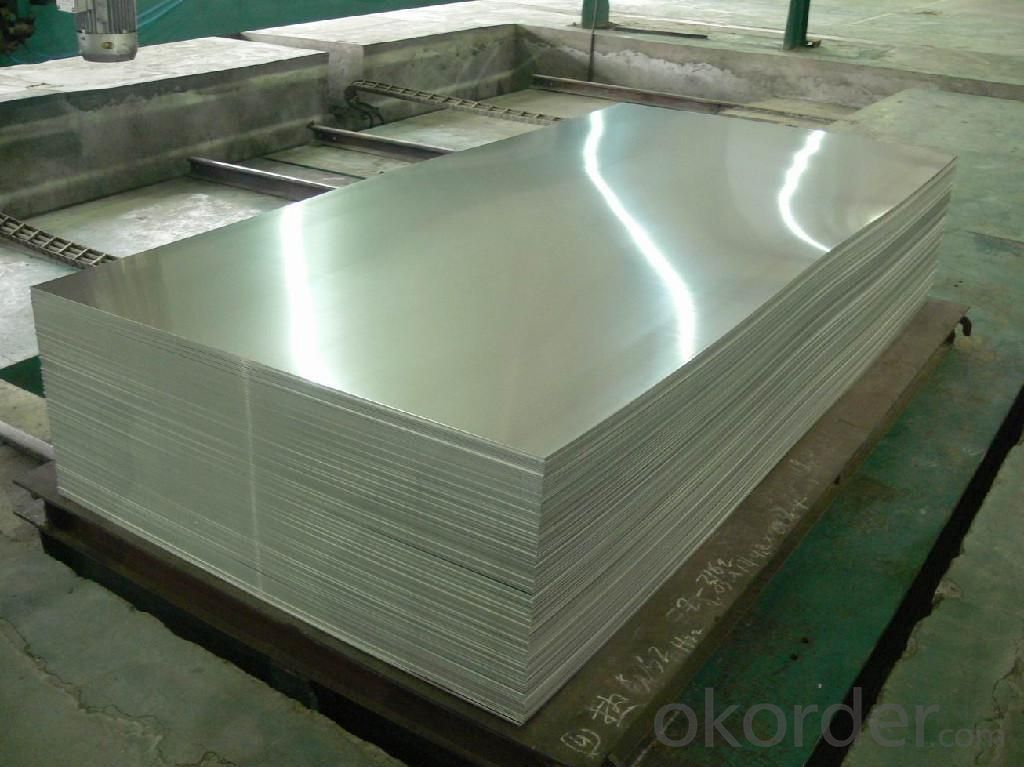

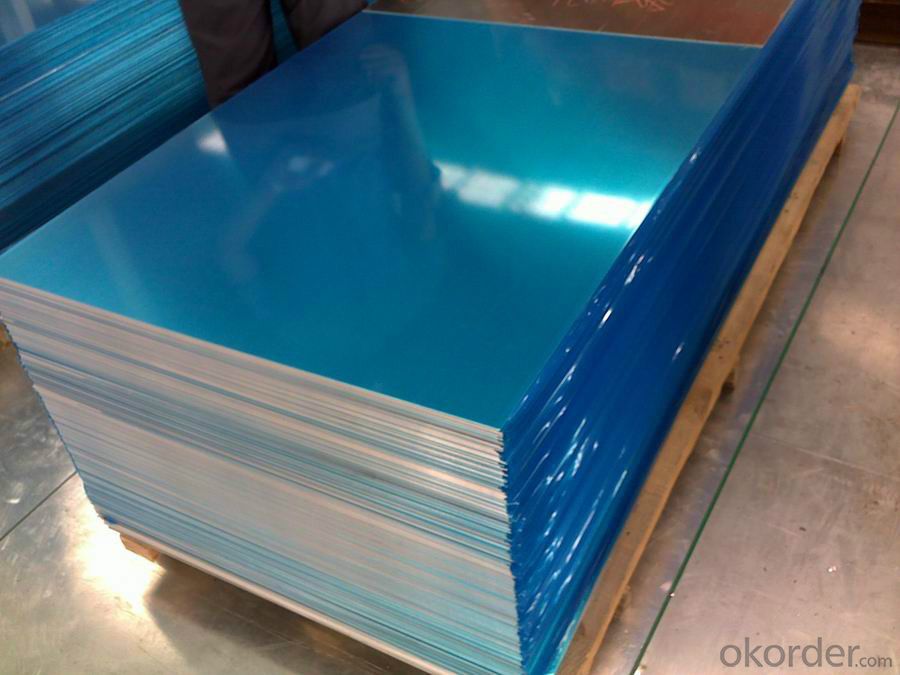

3.Aluminum Sheets AA1060 Used for Construction Images

4.Aluminum Sheets AA1060 Used for Construction Specification

Alloy | AA1060 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA1060 Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA1060 Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA1060 Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Can aluminum sheets be used for window frames?

- Yes, aluminum sheets can be used for window frames. Aluminum is a popular choice for window frames due to its durability, lightweight nature, and resistance to corrosion. It is also relatively easy to shape and provides good thermal insulation.

- Q: For my chem class that I just barely started taking, we're making bohr models. Even though my teacher explained it, I still dont get the concept of it all, like how the protons are lined up in their inner circle and the outer circles. I get everythign else about atoms except how they're actually made up lol. Maybe someone on here can explain it to me? I hope so because i have to make a model for it for friday.The element I'm asigned is aluminum btwYour help is greatly appreciated!

- This Site Might Help You. RE: Bohr Model?! Aluminum? For my chem class that I just barely started taking, we're making bohr models. Even though my teacher explained it, I still dont get the concept of it all, like how the protons are lined up in their inner circle and the outer circles. I get everythign else about atoms except how they're...

- Q: Are aluminum sheets suitable for interior design applications?

- Aluminum sheets are an excellent choice for interior design purposes. This material is both versatile and durable, allowing for various creative uses in enhancing the aesthetics of indoor spaces. Its malleability enables easy shaping, cutting, and manipulation, resulting in unique and contemporary designs. Different finishes, such as brushed, polished, or textured, further expand the design options. One major advantage of utilizing aluminum sheets in interior design is their lightweight composition. This feature simplifies handling and installation, reducing labor and transportation expenses. Additionally, aluminum's corrosion resistance makes it perfect for environments with high humidity or moisture, such as bathrooms or kitchens. Aluminum sheets find application in various aspects of interior design, including wall cladding, ceiling panels, room dividers, furniture, and decorative elements. The ability to paint or coat them in different colors allows seamless integration into any design scheme. Furthermore, perforation or engraving can create patterns or intricate designs, adding a distinct visual appeal to the space. Moreover, aluminum is a sustainable material with high recyclability. The recycling process consumes significantly less energy compared to the production of new aluminum, making it an environmentally friendly option for interior design applications. To summarize, the versatility, durability, lightweight nature, corrosion resistance, and manipulability of aluminum sheets make them highly suitable for interior design. They offer numerous design possibilities and can be used in various applications, rendering them a popular choice among designers and architects.

- Q: What are the common applications of aluminum sheets?

- Aluminum sheets are commonly used in various applications such as construction, automotive, aerospace, packaging, and electrical industries. They are used for making lightweight structures, including building facades, roofing, and cladding. In the automotive sector, aluminum sheets are used for manufacturing vehicle bodies and parts due to their high strength-to-weight ratio. They are also utilized in aircraft manufacturing for their low density and corrosion resistance. Additionally, aluminum sheets are popular in packaging as they are lightweight and can be easily formed into different shapes. In the electrical industry, they are used for wiring and conductors due to their excellent conductivity properties.

- Q: whst should I notice while welding aluminum sheet and aluminum block?

- two types of aluminum reach melting points, aluminum block must be preheated when you weld them with small current, you will know how to do it. You can use argon-arc welding back and forth, preheat it with small current.

- Q: doesn't particularly need to be welding but i need to make an air tight permanent seal around 2 very thin sheets of aluminium (like .02 inches thick) i was thinking .02 inch 5052 aluminum because its the thinnest i can find but am obviously up for suggestions.

- GOOP silicone adhesives are much harder when set than 100% silicone adhesives more commonly seen, but if you are just butting the tubes, epoxy to build a gusset would be a better choice. Always clean all surfaces with soap and water and then with denatured or high percent rubbing (isopropal) alcohol to improve bonding.

- Q: Can aluminum sheets be used for fencing?

- Yes, aluminum sheets can be used for fencing. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion. It is commonly used in fencing applications due to its ability to withstand harsh weather conditions, including rain, snow, and UV rays. Aluminum sheets can be easily fabricated into different fence styles and designs, such as picket fences, privacy fences, or decorative fences. Additionally, aluminum fencing requires minimal maintenance as it does not rust or rot like other materials such as wood or iron. Overall, aluminum sheets provide an excellent option for fencing due to their strength, longevity, and aesthetic appeal.

- Q: Can aluminum sheets be etched or engraved?

- Yes, aluminum sheets can be etched or engraved.

- Q: Are aluminum sheets suitable for bulletproof applications?

- No, aluminum sheets are not suitable for bulletproof applications.

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

Send your message to us

Aluminum Mesh Filter Sheets - AA1060 Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords