STS3201,202,310S 8K BA mirror Finished Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

| Product Description | |

| Product Name: | brushed stainless steel sheet |

| Item Number: | LJB4 |

| Material: | SUS201, SUS202, SUS304, SUS316L, SUS430 etc. |

| Color: | champange |

| Process: | polish, sand blast, pvd etc. |

| Dimension: | 1219*2438*1mm or customized |

| Origin of material: | POSCO, BAOSTEEL, or others |

| Protective film: | 7-10C PVC film from Germany |

| Packing: | standard shipping package |

| Delivery: | by ship or as you wish |

| Lead Time: | 7 days or more, depends |

| Applications: | for decorations of elevator, hotel, mall, KTV, club, kitchen etc. |

Chemical compasition

Product Chemical component Form %

C | S | Mn | P | S | Ni | Cr | Mo | |

S201 | ≤0.15 | ≤1.00 | ≤5.5-7.0 | ≤0.060 | ≤0.030 | 3.50-5.50 | 16.00-18.00 | --- |

S202 | ≤0.15 | ≤1.00 | ≤7.50-10.00 | ≤0.060 | ≤0.030 | 4.0-6.0 | 17.0-19.0 | --- |

S304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 8.00-11.00 | 17.00-19.00 | --- |

S304L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 8.00-12.00 | 18.00-20.00 | --- |

S316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 10.00-14.00 | 16.00-18.50 | --- |

S316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 12.00-15.00 | 16.00-18.00 | --- |

Finishings

2B | The surface brightness and flatness of 2B is better than 2D then theough a special surface treatment to improve its mechanical properties,2B could nearly Satisfy comprehensive uses |

No.3 | Polished with abrasive belt of git#100#200#,have better brightness with discontinuous coarse stria used as inner and external omaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit#150#180,have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtub buildings inner and extemal omaments electrical appliances kitchen utensils and food processing |

HL | Polished with abrasive belt of trit#150#320 on the NO.4 finish and has continuous streaks, mainly used as buildings omaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and food reflexivity like mirrorm kitchen apparatus, omament etc. |

8K | The product have excellent brightness and prefer reflexivity can be the mirror. |

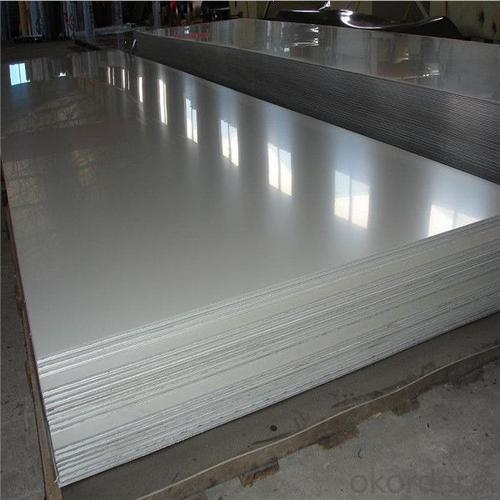

product shows

Detail information:

1. Steel grade: 310S

2. Surface: 2B, BA, No. 4, 8K(mirror), HL, embossing, etching. And more than 100 different patterns for your choice.

3. Colors: Golden, rose golden, titanium golden coating, champagne golden, brown, bronze, titanium black, sapphire blue, purple, gray, silver, coffee champagne, jade-green, etc.

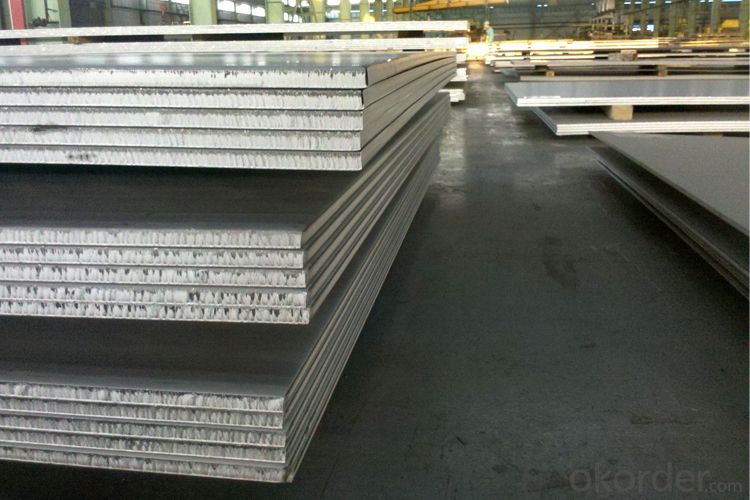

4. Thickness: 0.3-120mm

5. Width: 500mm, 1000mm, 1219mm, 1500mm, 1800. And length: Could be cut into any size as per customer's request. Usually our common sizes: 1219mm*2438mm (4*8ft), 1219mm*3048mm (4*10ft) and 1000mm*2000mm.

6. Standard: AISI, SUS, etc.

7. Packing: Standard sea-worthy packing, cover with PVC, and wooden case, or customize package.

8. Application:

Architectural decoration, luxury doors, wall decoration plate, elevators decorating, KTV indoor decoration, metal tank shell, ship building, decoration inside the train, as well as outdoor works, advertising name plate, the ceiling and cabinets, aisle panels, screen, the tunnel project, hotels, guest houses, entertainment place, kitchen equipment, light industrial and others.

9. Advantage: Colorful, showing the splendor of your quality, wear-resistant as well, strong corrosion resistance, anti-rust property and decorative effect, durable and beautiful in good taste.

10. Supplier Product Code: SDJM

11. Competitive Advantages of the product

1) Stainless Steel Decorative Sheet

2) Customize pattern and color coating

3) Advantage: Various patterns, splendid decorative effect, fashionable design

4) Surface finish: Mirror, 2b, no.1, no.4, 6k, 8k, polished, etc

- Q: Can the tile be directly attached to the stainless steel plate?

- Can be posted directly, with ordinary acid glass glue on the line, the real stainless acid, acid, glass, adhesive force a little stronger.

- Q: Which is better, stainless steel plate kitchen?

- Classification according to functional characteristics can be divided into non-magnetic stainless steel, easy to cut stainless steel, low temperature stainless steel, high strength stainless steel and so on. Because the stainless steel material with excellent corrosion resistance, formability, and compatibility in a wide temperature range, strong toughness characteristics, so get widely used in heavy industry, light industry, supplies industry and construction decoration industry.

- Q: Can stainless steel sheets be used for elevator door frames?

- Indeed, elevator door frames can certainly utilize stainless steel sheets. Elevator door frames commonly opt for stainless steel as it possesses exceptional durability, resistance to corrosion, and captivating aesthetic charm. This material is capable of enduring the continuous opening and closing actions and is impervious to the numerous cleansing agents employed in elevator upkeep. Moreover, stainless steel imparts a polished and contemporary appearance that harmonizes splendidly with the elevator's overall layout. Furthermore, stainless steel proves to be effortlessly cleanable and maintainable, rendering it a pragmatic selection for elevator door frames.

- Q: How do you prevent staining on stainless steel sheets?

- To avoid staining stainless steel sheets, there are several actions you can take: 1. Regularly clean the sheets using mild soap or detergent and warm water. Harsh chemicals and abrasive cleaners should be avoided as they can harm the surface. 2. Keep the sheets away from corrosive substances such as bleach, ammonia, and acidic cleaners. If spills occur, quickly rinse the affected area with water and thoroughly dry it. 3. Apply a protective coating or film to create a barrier between the surface and potential staining agents. There are various products designed specifically for stainless steel that can be used, such as protective sprays or polishes. 4. Properly maintain the sheets by regularly inspecting for any damage, scratches, or rust. Address any issues promptly by cleaning or repairing the affected areas to prevent staining. 5. Use soft cloths or non-abrasive sponges when cleaning or maintaining the sheets to avoid scratching the surface. Avoid using steel wool or abrasive materials that can cause marks or damage. 6. Ensure the sheets are thoroughly dried after cleaning to prevent water spots or mineral deposits. Use a clean, lint-free cloth to remove any moisture. 7. Handle the sheets with care to prevent scratching or damaging the surface. Avoid dragging or sliding heavy objects across them, as this can leave marks or cause abrasions. By following these preventive measures, you can maintain the appearance and integrity of stainless steel sheets and minimize the risk of staining.

- Q: Are stainless steel sheets available in different thicknesses?

- Stainless steel sheets of different thicknesses are readily available. They can be found in a range of thicknesses, from very thin to thick. For various applications, common thicknesses include 0.4mm, 0.5mm, 0.8mm, 1mm, 1.2mm, 1.5mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, and even thicker. The required thickness will depend on the intended use and the specific requirements of the project, whether they be structural or aesthetic. Different thicknesses of stainless steel sheets provide varying levels of strength, durability, and resistance to corrosion.

- Q: How do you prevent pitting or crevice corrosion on stainless steel sheets?

- To prevent pitting or crevice corrosion on stainless steel sheets, certain measures can be taken. First, ensuring proper cleaning and maintenance is crucial. Regularly cleaning the stainless steel sheets with mild detergent and water, followed by thorough rinsing and drying, helps remove any contaminants that can lead to corrosion. Additionally, avoiding exposure to corrosive substances like chloride-based cleaners or harsh chemicals is important. Applying a protective coating or passivating the stainless steel surface can also provide an extra barrier against corrosion. Passivation involves treating the stainless steel with a mild oxidizing agent to promote the formation of a passive oxide layer, which enhances the metal's resistance to corrosion. Proper design and installation practices are equally vital. Avoiding the use of dissimilar metals in contact with stainless steel sheets and ensuring proper sealing and gasketing in joints or crevices can prevent crevice corrosion. Adequate ventilation and avoiding stagnant conditions can also help minimize corrosion risks. Regular inspection and maintenance are necessary to identify and address any signs of corrosion promptly. This includes checking for signs of pitting or crevices, addressing any damage or scratches, and promptly repairing or replacing any corroded areas.

- Q: What are the different types of stainless steel sheet finishes?

- There are several types of stainless steel sheet finishes, including No. 1, 2B, No. 4, BA, and satin.

- Q: Comparison of three properties of aluminium plate, stainless steel plate and cold rolled plate?

- Cold-rolled steel plate is actually iron plate, with stainless steel plate characteristics, and the cost is low, but iron things, we know its shortcomings.

- Q: Can stainless steel sheets be used for storage racks?

- Yes, stainless steel sheets can be used for storage racks. Stainless steel is a durable and corrosion-resistant material, making it suitable for storing various items. It also has a high load-bearing capacity, making it ideal for heavy-duty storage applications.

- Q: How do you prevent rusting on stainless steel sheets?

- To prevent rusting on stainless steel sheets, you can implement a few preventive measures such as keeping the sheets clean and dry, avoiding exposure to corrosive substances, applying a protective coating or passivation treatment, and ensuring proper ventilation to minimize moisture buildup.

Send your message to us

STS3201,202,310S 8K BA mirror Finished Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords