Stainless Steel Sheet Price 309 3mm thickness ba finished

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Specifications about stainless steel sheet

Commodity | China supplier 3mm thickness ba finished stainless steel sheet price 309 |

Grade | 201,202,304,304L,316,316L,317L,310S,321,904L,409s,410,430 |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

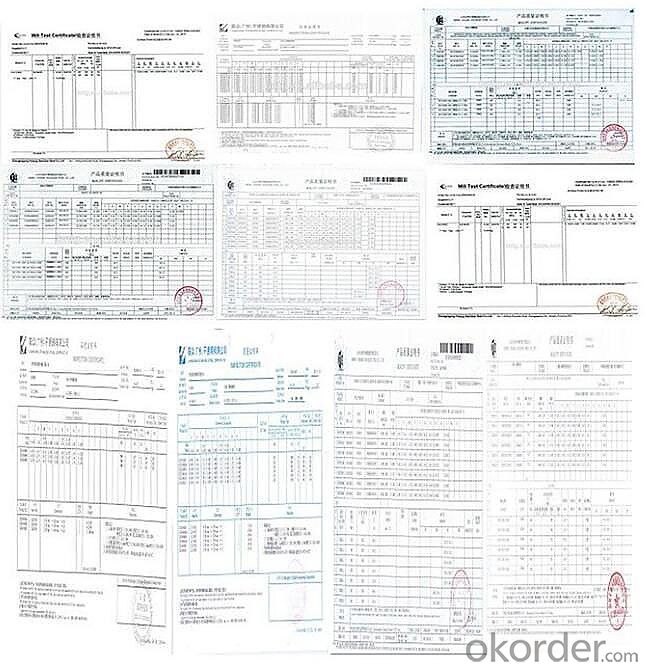

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.3-100mm or as customer’s requirement |

Width | 500-3000mm or as customer’s requirement |

Length | 1000-6000mm or as customer’s requirement |

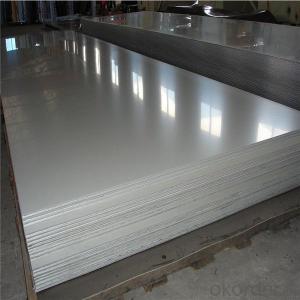

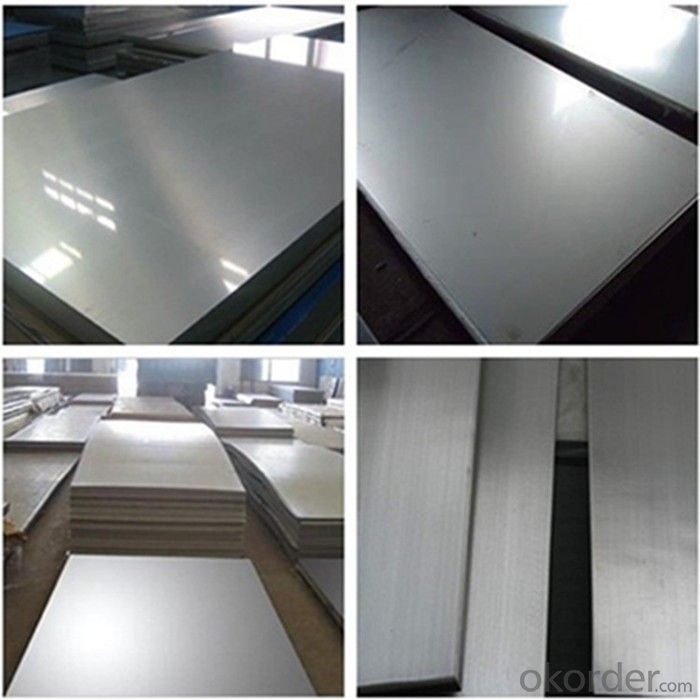

Surface | No.1 / No.4 / BA / 2B/HL/mirror/polished/brushed(bright annealed, surface not oxidati and brighter) |

Standard | JIS,AISI,ASTM,GB,DIN |

Delivery time | About10 days |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

Attention: the specifications can be customized .

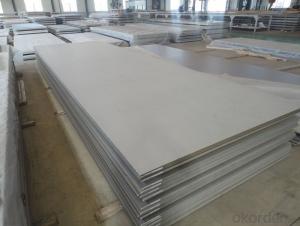

Product Show

Packaging & Shipping

Surface

Surface | Definition | Application |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

NO.3 | Those finished by polishing with No.100 to No.120 abravise specifiled in JIS R6001. | Kitchen utensils, Building construction |

NO.4 | Those finished by polishing with No.150 to No.180 abravise specifiled in JIS R6001. | Kitchen utensils, Building construction, Medical equipment |

HL | Those finished polishing so as to continuous polishing steaks by using abravise of suitable grain size. | Building construction |

BA(NO.6) | Those processed with bright treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction |

Mirror(NO.8) | Shinning like a mirror. | Building construction |

Our Services

Mill test certificate--stainless steel sheet

Application

- Q: Can stainless steel sheets be used for sink fabrication?

- Yes, stainless steel sheets can be used for sink fabrication. In fact, stainless steel is a popular material choice for sinks due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel sheets can be easily formed and welded to create a seamless sink design, as they are malleable and can be customized to fit specific dimensions and styles. Additionally, stainless steel is hygienic and easy to clean, making it a practical choice for kitchen and bathroom sinks.

- Q: How thick is 10gauge in stainless steel plate?

- The word "gauge" is interesting. This term is often seen in articles reading about metal roofs. It is not a unit of measurement, but a standard measure of width or thickness.

- Q: How do you determine the thickness of stainless steel sheets required for a specific application?

- To ascertain the necessary thickness of stainless steel sheets for a particular application, one must take into account various factors. 1. Load-bearing capacity: The initial step involves determining the maximum load that the stainless steel sheets will need to bear. This can be calculated by considering the weight of the objects or materials that will be placed on the sheets. It is essential to factor in any potential dynamic loads or impact forces that may be exerted. 2. Deflection limits: Deflection pertains to the degree of bending or sagging that occurs when a load is applied to the stainless steel sheets. The limits of deflection will depend on the specific application and the desired performance of the sheets. In general, minimizing deflection is vital for structural integrity and ensuring that the stainless steel sheets can withstand the intended load without excessive bending. 3. Material properties: Stainless steel sheets come in different grades, each possessing its own mechanical properties. The tensile strength, yield strength, and hardness of the stainless steel should be taken into consideration to ensure it can withstand the required load and any potential environmental conditions, such as corrosion or extreme temperatures. 4. Safety factors: It is crucial to incorporate appropriate safety factors to provide a margin of safety for the stainless steel sheets. Safety factors account for uncertainties in load calculations, material properties, and other variables. The safety factor may vary depending on the desired level of confidence, but it is typically recommended to apply a safety factor of at least 1.5 to 2. 5. Industry standards and regulations: Depending on the specific application, there may be industry standards or regulations that specify the minimum thickness requirements for stainless steel sheets. It is important to consult these standards and ensure compliance to guarantee that the sheets meet all safety and performance requirements. By considering these factors and conducting engineering calculations, one can determine the appropriate thickness of stainless steel sheets needed for a specific application. It is always advisable to consult with an experienced engineer or a reputable stainless steel supplier to ensure accurate calculations and to address any specific requirements or unique considerations pertaining to the application.

- Q: Can stainless steel sheets be used in the construction industry?

- Yes, stainless steel sheets can be used in the construction industry. They are commonly used for a variety of applications including roofing, cladding, structural supports, and interior finishes. Stainless steel offers excellent corrosion resistance, durability, and aesthetic appeal, making it a popular choice for construction projects.

- Q: Are stainless steel sheets suitable for electrical enclosures?

- Yes, stainless steel sheets are suitable for electrical enclosures. Stainless steel is known for its excellent strength, corrosion resistance, and durability, making it an ideal material for protecting electrical components. It provides a high level of protection against environmental factors such as moisture, dust, and extreme temperatures. Additionally, stainless steel has good electrical conductivity, which is crucial for proper grounding and shielding. It also offers good electromagnetic compatibility (EMC), reducing the risk of electromagnetic interference (EMI) in sensitive electrical equipment. Moreover, stainless steel is easy to clean and maintain, ensuring a long-lasting and reliable enclosure for electrical applications.

- Q: What are the main chemical constituents of stainless steel plates?

- Stainless steel not only refers to a stainless steel, but more than one hundred kinds of industrial stainless steel, the development of each kind of stainless steel in its specific application areas have good performance. The key to success is to find out what the purpose is, and then determine the correct type of steel. There are usually only six kinds of steel related to the application of building construction. They all contain 17 to 22% chromium, and better steel also contains nickel. The addition of molybdenum can further improve atmospheric corrosion, especially for atmospheric corrosion resistant chlorides.

- Q: What are the weight calculations for stainless steel sheets?

- The weight calculations for stainless steel sheets can be determined using the following formula: Weight (in pounds) = Thickness (in inches) x Width (in inches) x Length (in inches) x Density (in pounds per cubic inch) The density of stainless steel typically ranges from 0.283 to 0.305 pounds per cubic inch, depending on the specific alloy used. Therefore, it is important to determine the specific density value for the particular grade of stainless steel being used. For example, let's say we have a stainless steel sheet with a thickness of 0.125 inches, a width of 36 inches, and a length of 72 inches. If the density of the stainless steel is 0.283 pounds per cubic inch, the weight calculation would be: Weight = 0.125 inches x 36 inches x 72 inches x 0.283 pounds per cubic inch = 91.368 pounds So, the weight of this stainless steel sheet would be approximately 91.368 pounds.

- Q: What are the different types of surface finishes available for stainless steel sheets?

- There are several types of surface finishes available for stainless steel sheets, each with its own unique characteristics and applications. 1. No. 1 Finish: This is the most common and widely used finish for stainless steel sheets. It is hot rolled and annealed, resulting in a rough, dull appearance with visible grain lines. No. 1 finish is suitable for applications where a rough surface texture is desired, such as industrial or structural uses. 2. No. 2B Finish: This finish is achieved by cold rolling the stainless steel sheet after a No. 1 finish, followed by annealing and descaling. It has a smooth, reflective surface with a slight matte appearance. No. 2B finish is commonly used for applications requiring a clean, aesthetic look, such as kitchen appliances, architectural accents, and decorative items. 3. No. 3 Finish: Also known as a brushed finish, this type of surface finish is achieved by mechanically polishing the stainless steel sheet with abrasive materials. It creates a unidirectional pattern of fine lines, giving the metal a satin-like appearance. No. 3 finish is often used for decorative purposes, such as furniture, signage, and elevator doors. 4. No. 4 Finish: Similar to No. 3 finish, No. 4 finish is achieved by mechanically polishing the stainless steel sheet, but with finer abrasives. It produces a smoother, more refined surface with a low gloss. No. 4 finish is commonly used for applications requiring good corrosion resistance and easy maintenance, such as kitchen equipment, automotive trim, and architectural components. 5. No. 8 Mirror Finish: This is the most reflective and luxurious surface finish for stainless steel sheets. It involves polishing the metal with progressively finer abrasives until a highly reflective mirror-like surface is achieved. No. 8 mirror finish is often used for decorative and high-end applications, such as architectural accents, jewelry, and luxury consumer goods. 6. Embossed Finish: This finish involves stamping or pressing a pattern onto the stainless steel sheet, creating a textured surface. Embossed finishes can vary from simple designs to intricate patterns, offering both aesthetic appeal and improved slip resistance. They are commonly used for applications requiring both functionality and visual interest, such as flooring, countertops, and wall cladding. Overall, the choice of surface finish for stainless steel sheets depends on the desired appearance, functionality, and performance requirements of the specific application.

- Q: How do you remove heat discoloration from stainless steel sheets?

- To effectively remove heat discoloration from stainless steel sheets, various techniques can be employed. One effective approach involves utilizing a specialized stainless steel cleaner or polish specifically formulated for eliminating heat discoloration. These products often contain gentle abrasives that aid in removing the discolored layer. Adhering to the instructions provided, apply the product to the affected area using a soft cloth or sponge. Employ a gentle circular motion while rubbing, then rinse the surface with water and thoroughly dry it. Another viable option entails creating a paste by combining equal parts baking soda and water. Apply this mixture to the discolored region and gently rub it in using a soft cloth. Rinse thoroughly with water and dry the surface completely. Should the discoloration persist despite previous attempts, employing a stainless steel scratch eraser or fine-grit sandpaper can be considered. It is crucial to exercise caution when using these methods, as they possess the potential to scratch the stainless steel surface. Always conduct a preliminary test in a small, inconspicuous area and proceed with care. It is worth emphasizing that preventing heat discoloration is key to maintaining stainless steel sheets' appearance. Utilizing heat-resistant pads or trivets beneath hot pots and pans can effectively hinder heat transfer to the stainless steel surface. Additionally, avoiding direct contact with high heat sources, such as keeping stainless steel sheets at a safe distance from stovetops or ovens, can significantly minimize the occurrence of discoloration.

- Q: Are stainless steel sheets resistant to high-pressure environments?

- Yes, stainless steel sheets are highly resistant to high-pressure environments. Stainless steel is a strong and durable material that can withstand the pressure exerted by various industrial processes, such as hydraulic systems, chemical processing plants, and oil and gas pipelines. It is known for its excellent tensile strength and ability to maintain its structural integrity even under extreme pressure conditions. Additionally, stainless steel is also resistant to corrosion, which further enhances its suitability for high-pressure environments where exposure to moisture or chemicals is common. Overall, stainless steel sheets are widely used in industries that require materials capable of withstanding high-pressure conditions due to their exceptional strength and resistance properties.

Send your message to us

Stainless Steel Sheet Price 309 3mm thickness ba finished

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords