310s Stainless Steel Plate/Sheet with BA Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless Steel Plate 310S

Brand name :

Technique: hot rolled or cold rolled

Type : plate

Model number :310S(0Cr25Ni20/1Cr25Ni20Si2)

Thickness : Cold Rolled: 0.3-3, 4, 5,6mm; Hot rolled: 3-120mm

Width :1219mm/1500mm/1800mm or as request

Length : 2438/3000/6000mm, size can be customized

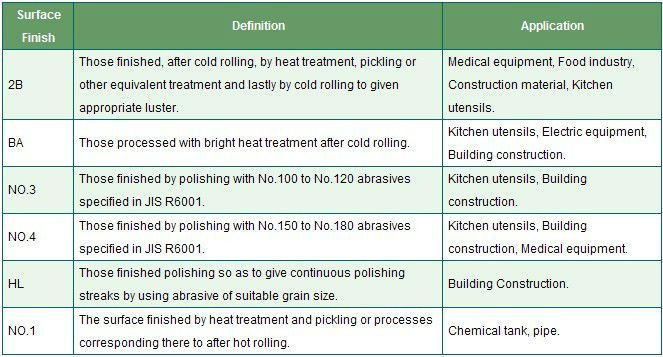

Finish: Cold Rolled: 2B, 2D, BA, NO.4, HL, 8K; Hot Rolled: NO.1, 4K, Polished.

Payment terms: T/T, 30% of value prepaid after signing S/C within three working days, and the balance against the copy of B/L.

Package :standard packing or at customer's request.

Standard :ASTM AISI GB

Certification: ISO

Applications :Widely used in the fields related to chemical equipment and heat resistant parts, and typecally applied in saggers, drying equipment, industrial furnace lining, heat-exchangers, petroleum refinery equipment, etc

TISCO China 310S stainless steel plate price per ton

GRADE | 310s | |

SURFACE | Cold Rolled :2B/NO.4/HL/BA/8K | Hot rolled :NO.1 |

WIDTH(mm) | 1000mm ,1219mm ,1250mm , 1500mm ,1600mm ,1800mm,2000mm ,2500mm etc. | |

THICKNESS(mm) | Cold Rolled :0.3mm,0.4mm,0.5mm,0.6mm,0.7mm, 0.8mm,0.9mm,1.0mm,1.2mm,1.5mm,2.0mm,2.5mm,3.0mm

Hot rolled :3.0mm ,4.0mm,5.0mm,6.0mm,8.0mm,10.0mm, 12.0mm,14.0mm,16.0mm,18.0mm,20.0mm,22.0mm,25.0mm, 28.0mm,30.0mm,32.0mm,35.0mm,38.0mm,40.0mm etc. | |

LENGTH(mm) | According to customer requirements | |

Surface finishes and characteristic

310s Chemical Composition | ||||||

C | Si | Mn | Cr | Ni | S | P |

≤0.08 | ≤1.00 | ≤2.00 | 24.0~26.0 | 19.0~22.0 | ≤0.030 | ≤0.035 |

mechanical properties:

Mechanical properties | |||||||

Heat Treatment | Yield strength(N/mm2) | Tensile strength | Elongation(%) | Hardness | |||

HB | HRB | HV | |||||

310S | S | ≥205 | ≥520 | ≥40 | ≤187 | ≤90 | ≤200 |

Surface finishes and characteristic

- Q: Can stainless steel sheets be used for power generation equipment?

- Stainless steel sheets are indeed applicable for power generation equipment. With its versatility, stainless steel possesses a range of advantageous qualities specifically tailored for power generation applications. Its corrosion resistance is exceptional, a paramount characteristic for equipment that comes into contact with water, steam, or other corrosive substances. Moreover, stainless steel exhibits remarkable strength and durability, enabling it to withstand the elevated temperatures and pressures frequently encountered in power generation systems. Another notable attribute is its proficiency as an electrical conductor, rendering it suitable for electrical components and connections within the equipment. Consequently, stainless steel sheets are widely employed in the construction of power generation equipment, including turbines, boilers, heat exchangers, and exhaust systems.

- Q: Do stainless steel sheets have a warranty?

- Yes, stainless steel sheets generally come with a warranty. The duration and terms of the warranty may vary depending on the manufacturer and the specific product. It is always recommended to check with the supplier or manufacturer for the details of the warranty coverage. Typically, the warranty covers defects in material or workmanship and provides a replacement or repair of the stainless steel sheet if any issues arise within the specified warranty period. It is important to follow the manufacturer's care and maintenance instructions to ensure the validity of the warranty.

- Q: Can stainless steel sheets be used for medical equipment?

- Indeed, medical equipment can utilize stainless steel sheets. The medical industry extensively employs stainless steel due to its remarkable resistance to corrosion, its durability, and its ease of cleaning. Surgical instruments, implants, medical devices, and equipment like sterilization trays, hospital beds, and operating room tables are commonly manufactured using stainless steel. As it does not react with bodily tissues or fluids, stainless steel is a secure and sanitary option for medical purposes. Moreover, it can endure numerous sterilization procedures without compromising its qualities, thus rendering it perfectly suited for hospitals and healthcare facilities.

- Q: Can stainless steel sheets be used for airport terminals?

- Airport terminals can indeed make use of stainless steel sheets. Stainless steel, being an incredibly adaptable material, offers numerous advantages when employed in airport terminals. Initially, stainless steel boasts corrosion resistance, a crucial feature in a bustling environment like an airport where exposure to moisture and chemicals is commonplace. This characteristic guarantees that the structural integrity and appearance of the stainless steel sheets will endure over time. Furthermore, stainless steel sheets possess durability, enabling them to withstand heavy foot traffic and the wear and tear associated with airport operations. Consequently, they can be utilized for a variety of purposes within the terminal, including walls, ceilings, cladding, countertops, and furniture. Additionally, stainless steel is easy to clean and maintain, making it a hygienic choice for areas with high foot traffic, such as airport terminals. Moreover, stainless steel brings forth an aesthetic appeal that can enhance the overall design of the airport terminal. Its sleek and modern appearance can create a sense of sophistication and elegance. Stainless steel sheets are available in different finishes, such as brushed, polished, or patterned, allowing for customization to meet the desired aesthetic requirements of the terminal. In conclusion, due to their corrosion resistance, durability, ease of maintenance, and aesthetic versatility, stainless steel sheets prove to be a practical and visually pleasing option for airport terminals.

- Q: How do you prevent galvanic corrosion on stainless steel sheets?

- One way to prevent galvanic corrosion on stainless steel sheets is to ensure that they are not in direct contact with dissimilar metals. This can be achieved by using insulating materials, such as rubber gaskets or plastic washers, between the stainless steel sheets and any other metal surfaces they come into contact with. Additionally, regular cleaning and maintenance of the stainless steel sheets can help remove any potential corrosive agents and minimize the risk of galvanic corrosion.

- Q: How do I select the appropriate thickness for stainless steel sheets?

- To select the appropriate thickness for stainless steel sheets, you need to consider factors such as the application, desired durability, strength requirements, and cost. Thicker sheets are generally more durable and offer higher strength, but they may also be more expensive. It is advisable to consult with a stainless steel supplier or industry expert who can assess your specific needs and provide guidance on the most suitable thickness for your project.

- Q: How do you prevent warping of stainless steel sheets?

- There are several measures that can be taken to prevent warping of stainless steel sheets. These include: 1. Storage and handling: Stainless steel sheets should be stored in a clean and dry environment, away from moisture or excessive heat. It is important to handle the sheets carefully, avoiding any unnecessary bending or pressure that could cause warping. 2. Welding techniques: When welding stainless steel sheets, it is crucial to use the correct techniques and procedures. Proper heat control and weld placement can help minimize the risk of warping. Preheating the sheets before welding can also prevent distortion. 3. Stress relieving: This involves heating the stainless steel sheets to a specific temperature and then cooling them slowly. Stress relieving helps eliminate residual stresses that could lead to warping. 4. Support during machining: Proper support is important when machining stainless steel sheets to prevent warping. Clamps or fixtures can be used to securely hold the sheets in place. 5. Minimize heat exposure: It is important to avoid prolonged exposure to high temperatures during processes like cutting, grinding, or forming. Using coolants or lubricants during these processes can dissipate heat and minimize the risk of warping. 6. Choose the right grade and thickness: Selecting the appropriate grade and thickness of stainless steel sheets for a specific application is essential. Thicker sheets generally have more resistance to warping, while certain grades may be more prone to distortion. Consulting with a materials expert or engineer can help in selecting the right stainless steel sheets for a project. By implementing these preventive measures, the risk of warping stainless steel sheets can be significantly reduced, ensuring their integrity and longevity.

- Q: Are stainless steel sheets suitable for heat transfer equipment?

- Yes, stainless steel sheets are indeed suitable for heat transfer equipment. Stainless steel has excellent thermal conductivity, which allows for efficient heat transfer. It also has high corrosion resistance and can withstand high temperatures, making it a reliable choice for various heat transfer applications.

- Q: How do I bend or form stainless steel sheets?

- To bend or form stainless steel sheets, you can follow these steps: 1. Choose the appropriate stainless steel grade: Stainless steel comes in various grades, each with specific properties. Select the grade that best suits your project's requirements, considering factors like corrosion resistance, strength, and formability. 2. Use the right tools: To bend stainless steel sheets, you will need specific tools such as a hydraulic press brake or a metal bending machine. These tools apply force evenly to achieve precise and consistent bends. Make sure to use tools that are designed for stainless steel to avoid damaging the material. 3. Prepare the stainless steel sheet: Before bending, ensure that the stainless steel sheet is clean and free from any dirt or debris. Additionally, mark the desired bending lines on the sheet using a pencil or tape to guide you during the process. 4. Determine the bending angle and radius: Determine the angle and radius of the bend you want to achieve. This will depend on the specific requirements of your project. Use a protractor or a template to measure and mark the desired angles accurately. 5. Secure the stainless steel sheet: To prevent movement or slipping during the bending process, securely clamp the stainless steel sheet to the bending tool or machine. This will ensure stability and accuracy during the bending process. 6. Apply pressure gradually: Start the bending process slowly and gradually increase the pressure. This prevents the stainless steel sheet from cracking or warping. Monitor the bending carefully to ensure that the desired shape is achieved without any defects or deformation. 7. Repeat if necessary: If you need to create multiple bends or complex shapes, repeat the process as required. Ensure that each bend is carefully measured and aligned with the previous bends to achieve a consistent and accurate result. 8. Finishing touches: After bending the stainless steel sheet, remove any residual marks or burrs using a file or sandpaper. This will give your finished product a smooth and polished appearance. Remember, bending stainless steel sheets can be challenging, especially for thicker gauges or harder grades. It is advisable to practice on scrap pieces or seek professional assistance if you are unsure or lack experience in working with stainless steel.

- Q: Are stainless steel sheets resistant to sulfuric acid?

- Yes, stainless steel sheets are generally resistant to sulfuric acid.

Send your message to us

310s Stainless Steel Plate/Sheet with BA Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords