Mild Steel Square Billet Bar for Rebar Production

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Mild Steel Square Billet Bar for Rebar Production Description:

Mild steel square billet bar for rebar production is a bar with square shaped cross-section. It is special case of equal sides. Before steel products are sold on the market, the steel must first be processed into more functional pieces. Raw steel cannot be of use while in its pure form, thus it has to be cast into shape. The freshly made steel, mild steel square billet bar for rebar production is still in the form of a metal bar or rectangle. Small sizes of mild steel square billet bar for rebar production are used in ship building.

2. Main Features of Mild Steel Square Billet Bar for Rebar Production:

• Grade: Q235

• Type: Mild carbon steel

• A quadrilateral with four equal sides and four right angles.

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

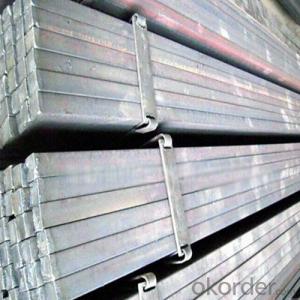

3. Mild Steel Square Billet Bar for Rebar Production Images:

4. Mild Steel Square Billet Bar for Rebar Production Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①What is the main material?

There are two types of Square Bar, one is hot rolled square bar and other one is cold drawn square bar. Our principal products is hot rolled square bar. We dedicate to products with material Q195 and Q235. We offer products with high quality and low price.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: Can a steel square be used for rafter layout and construction?

- Yes, a steel square can be used for rafter layout and construction. A steel square is a versatile tool that is commonly used by carpenters and builders for laying out and constructing rafters. It helps in determining the length and angles of the rafters, as well as marking and cutting them accurately. The steel square typically has measurements and angles engraved on its surface, which makes it easy to use for various rafter calculations and layouts. Additionally, the durability and stability of steel make it a reliable tool for rafter construction, ensuring precise and accurate results.

- Q: How do you use a steel square to measure and mark 202.5-degree angles?

- To use a steel square to measure and mark a 202.5-degree angle, you will need to follow a few steps. First, ensure that your steel square is accurate and in good condition. Place one arm of the square against the edge of the material or surface you want to mark. Next, locate the degree scale on the steel square. This scale is usually located on the longer arm of the square and is marked with various angles. Find the 0-degree mark on the scale and align it with the arm of the square against your material. Then, move your eyes along the scale until you reach the 202.5-degree mark. This may be indicated by a small tick mark or a number, depending on the type of steel square you have. Once you have found the 202.5-degree mark, hold the square firmly in place and use a pencil or marking tool to make a small mark on your material. This mark indicates the desired angle of 202.5 degrees. You can then use a straightedge or ruler to connect this mark with other reference points or lines as needed. Remember to always double-check the accuracy of your measurements and markings before proceeding with any cutting or other actions.

- Q: What are the different markings on a steel square and their uses?

- There are several markings on a steel square that serve different purposes. The most common markings are the graduations along the blade and tongue, which are used to measure and mark lengths or angles. The numbers on these graduations indicate inches, centimeters, or degrees, depending on the type of square. Additionally, there may be markings for rafter tables, brace tables, or other construction-related calculations. These markings help carpenters and other tradespeople quickly and accurately perform various tasks, such as marking cuts or determining angles.

- Q: How do you use a steel square to lay out a perpendicular line?

- To use a steel square to lay out a perpendicular line, you would align the long edge of the square against the reference line or surface. Then, make sure the short edge of the square is flush with the reference line or surface. Finally, using a pencil or scribe, mark a line along the perpendicular edge of the square, ensuring it is at a 90-degree angle to the reference line.

- Q: Can a steel square be used for shed post layout and installation?

- Yes, a steel square can be used for shed post layout and installation. Steel squares, also known as framing squares or carpenter's squares, are versatile tools that can be used for various woodworking projects, including shed construction. They provide accurate measurements and angles, making them suitable for marking and aligning posts during layout and installation.

- Q: What are some common techniques for using a steel square in guitar making?

- Some common techniques for using a steel square in guitar making include measuring and marking straight lines, ensuring accurate angles for cutting and drilling, checking the alignment of components such as the neck and bridge, and setting up the right angle for installing frets. Additionally, a steel square can be used as a guide for sanding and shaping the guitar body or neck.

- Q: How do you use a steel square to mark cutting lines?

- To use a steel square to mark cutting lines, first position the square against the edge of the material you want to cut. Align one side of the square with the edge of the material, ensuring it is perpendicular to the edge. Hold the square firmly in place. Then, using a pencil or a scribe, trace along the inside edge of the square to mark your cutting line accurately.

- Q: Can a steel square be used for marking out lap joints?

- Yes, a steel square can be used for marking out lap joints.

- Q: Can a steel square be used for making 90-degree corners?

- A 90-degree corner can be made using a steel square. The steel square, also called a framing square or carpenter's square, is a versatile tool that is commonly used in woodworking and construction. It consists of two arms, one long and one short, which are joined at a 90-degree angle. Typically, the long arm measures 24 inches while the short arm measures 16 inches. The squareness of the tool's arms enables accurate measurement and marking of 90-degree angles. By aligning the long arm with one edge of a material and the short arm with another edge, you can ensure that the two edges meet perfectly at a right angle, thus forming a 90-degree corner. The steel square is a dependable and widely utilized tool for creating precise corners in various applications.

- Q: What are the different ways to hold a steel square?

- There are several different ways to hold a steel square, depending on the specific task at hand and personal preference. Here are some common methods: 1. Finger grip: This is the most basic and common way to hold a steel square. Simply grasp the square firmly with your fingers and thumb, ensuring a secure grip. 2. Palm grip: For better control and stability, some people prefer to hold the steel square in their palm, with their fingers wrapped around the handle. This grip allows for more precision and accuracy when using the square. 3. Thumb grip: Another common method is to hold the steel square with your thumb on one side of the handle and your fingers on the other side. This grip provides stability and control while allowing your fingers to remain free for other tasks. 4. Hook grip: In certain situations, it may be necessary to hang the steel square on an edge or hook it onto a surface for stability. In this case, you can hold the square by placing your fingers through the holes or slots in the handle, creating a hook-like grip. 5. Clamped grip: When using a steel square for more complex tasks, such as woodworking or metalworking, it may be beneficial to secure the square in place using clamps or vices. This ensures that the square remains fixed, allowing for precise measurements and marking. Ultimately, the way you hold a steel square depends on your comfort, the task at hand, and the level of control and stability required. It's important to find a grip that allows you to work safely and effectively while using the square.

Send your message to us

Mild Steel Square Billet Bar for Rebar Production

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords