Steel Rebar Production Line

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

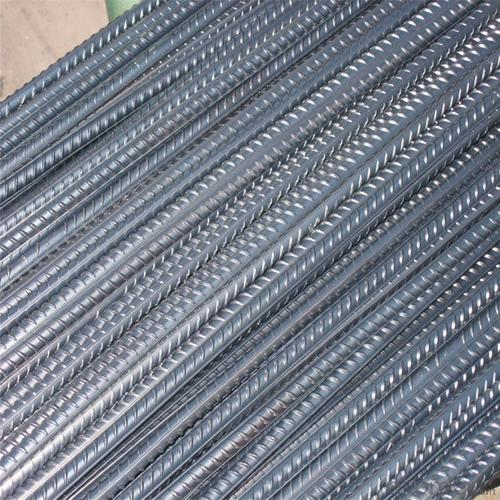

Steel Rebar Production Line

Description of Steel Rebar Production Line

1, Diameter: 5.5mm-10mm Steel Rebar Production Line

10m- 40mm Steel Rebar Production Line

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Steel Rebar Production Line

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

Products Show of Steel Rebar Production Line

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: Can special steel be used for making power generation equipment?

- Yes, special steel can be used for making power generation equipment. Special steels are specifically designed to have enhanced properties such as high strength, corrosion resistance, heat resistance, and wear resistance. These properties make special steel suitable for use in demanding applications such as power generation equipment, which often operates under high temperatures and pressures. Power generation equipment, such as turbines, boilers, and generators, require materials that can withstand harsh operating conditions and deliver reliable performance over an extended period. Special steel grades, such as stainless steels, nickel-based alloys, and heat-resistant steels, are commonly used in the construction of power plants and power generation equipment. Stainless steels are frequently used in power generation due to their excellent corrosion resistance, which is crucial for equipment exposed to high moisture or aggressive environments. Nickel-based alloys are renowned for their exceptional high-temperature strength, making them ideal for components subjected to extreme heat, such as turbine blades or exhaust systems. Heat-resistant steels, on the other hand, are specifically designed to retain their mechanical properties at elevated temperatures, making them suitable for applications such as boilers and heat exchangers. In summary, special steel offers a range of desirable properties that make it highly suitable for manufacturing power generation equipment. Its strength, corrosion resistance, heat resistance, and wear resistance make it an excellent choice for withstanding the demanding conditions found in power plants and ensuring the reliable and efficient generation of electricity.

- Q: How does special steel contribute to the construction aftermarket industry?

- Special steel plays a crucial role in the construction aftermarket industry by offering a wide range of benefits and applications. Firstly, special steel possesses exceptional strength and durability, making it an ideal material for constructing various infrastructure elements such as bridges, buildings, and roads. Its high tensile strength allows for greater load-bearing capacity, increasing the overall safety and longevity of structures. Additionally, special steel is known for its resistance to corrosion and extreme weather conditions, which is particularly important in construction projects. By using special steel, construction companies can ensure that their structures are better equipped to withstand harsh environments, reducing the need for frequent repairs and replacements. Moreover, special steel provides versatility in terms of fabrication and design. It can be easily molded and shaped into different forms, allowing architects and engineers to create innovative and aesthetically pleasing structures. This flexibility enables the construction aftermarket industry to meet various design requirements while maintaining structural integrity. Furthermore, special steel offers cost-effectiveness in the long run. Although the initial investment in special steel may be higher than other materials, its durability and low maintenance requirements result in reduced lifecycle costs. This makes it a cost-efficient choice for construction projects, as it minimizes ongoing expenses related to repairs and replacements. Lastly, special steel contributes to sustainability in the construction industry. Due to its strength and durability, structures built with special steel have a longer lifespan, reducing the need for frequent demolitions and rebuilds. Additionally, special steel is highly recyclable, allowing for a more sustainable approach to construction by minimizing waste and conserving resources. In conclusion, special steel plays a significant role in the construction aftermarket industry by providing superior strength, durability, resistance, versatility, cost-effectiveness, and sustainability. Its unique properties contribute to safer, longer-lasting, and more aesthetically pleasing structures, making it an essential material for construction projects.

- Q: What are the factors to consider when selecting special steel for a specific application?

- When selecting special steel for a specific application, some important factors to consider include the required strength and hardness, corrosion resistance, temperature resistance, machinability, weldability, and cost. Other factors may include the desired surface finish, dimensional stability, availability, and any specific industry or regulatory requirements.

- Q: What are the applications of special steel in the marine sector?

- Marine grade steel, also known as special steel, finds a wide range of applications in the marine sector. Shipbuilding is one key use of this steel in the industry, as its high resistance to corrosion makes it perfect for constructing ships and other marine vessels constantly exposed to harsh weather conditions and saltwater. Another significant application of special steel in the marine sector is for offshore structures. Materials used in offshore platforms like oil rigs and wind turbines need to withstand the harsh marine environment, including corrosion, high pressure, and extreme temperatures. Special steel's exceptional strength and durability make it the preferred choice for these structures. Furthermore, special steel is employed in the manufacturing of marine equipment and components. For instance, propeller shafts, anchor chains, and underwater pipelines often use special steel due to its excellent mechanical properties and corrosion resistance. Marine engines also rely on special steel to ensure reliable performance and longevity. Moreover, special steel is utilized in the construction of port infrastructure such as piers, docks, and harbor structures. These structures must endure constant exposure to seawater, heavy loads, and dynamic forces, making special steel an ideal material choice for their construction. In conclusion, special steel plays a vital role in the marine sector with its numerous applications. Its corrosion resistance, strength, and durability make it an essential material for shipbuilding, offshore structures, marine equipment, and port infrastructure. The utilization of special steel ensures the longevity and reliability of marine assets operating in harsh marine environments.

- Q: How is wear-resistant stainless steel used in the production of cutting tools?

- Wear-resistant stainless steel is commonly used in the production of cutting tools due to its high hardness and resistance to wear and corrosion. This steel alloy is essential for making durable and long-lasting cutting tools, such as knives, blades, drills, and saws. The wear resistance of stainless steel ensures that these tools can withstand the friction and abrasion involved in cutting various materials, leading to improved performance and extended tool life.

- Q: What are the requirements for special steel used in high-pressure applications?

- The requirements for special steel used in high-pressure applications typically include high strength, excellent resistance to corrosion and oxidation, good weldability, and the ability to withstand extreme temperatures and pressures without deformation or failure. Additionally, the steel should have a high level of toughness to withstand impact and fatigue loads, as well as good dimensional stability to ensure proper sealing and performance in high-pressure environments.

- Q: How does special steel contribute to the defense aerospace industry?

- Special steel contributes to the defense aerospace industry by providing high-strength, lightweight, and corrosion-resistant materials for the construction of critical components such as aircraft frames, landing gear, and engine parts. These steels are specifically designed to withstand extreme conditions, including high temperatures and pressures, ensuring the safety and reliability of military aircraft. Additionally, special steel's superior mechanical properties enhance fuel efficiency, increase payload capacity, and improve overall performance, making it an essential material in the defense aerospace sector.

- Q: How is boron steel used in automotive safety applications?

- Boron steel is used in automotive safety applications due to its high strength and ability to absorb and distribute impact energy. It is commonly used in the construction of safety cages, reinforcements, and components such as side impact beams, door beams, and crash boxes. Its exceptional crashworthiness properties help improve the structural integrity of vehicles, enhance occupant protection, and reduce the risk of serious injuries during accidents.

- Q: What are the specific requirements for special steel used in the chemical industry?

- Special steel used in the chemical industry must meet specific requirements in order to ensure optimal performance and safety. Some of the key requirements for special steel in the chemical industry include: 1. Corrosion resistance: Special steel used in the chemical industry must possess high resistance to corrosion, as it will be exposed to various aggressive chemicals and corrosive environments. This means that the steel should be able to withstand the corrosive effects of acids, alkalis, and other chemicals commonly used in the industry. 2. High temperature resistance: The steel should have excellent heat resistance to withstand high operating temperatures often encountered in chemical processes. This is important to ensure that the steel does not degrade or lose its strength when exposed to elevated temperatures. 3. Mechanical strength: Special steel used in the chemical industry should have superior mechanical strength to withstand the high stress and pressure that can occur during chemical processes. It should be able to maintain its structural integrity even under challenging conditions. 4. Resistance to fatigue and stress: The steel should have good resistance to fatigue and stress, as it will be subjected to cyclic loading and pressure variations during operation. This is crucial to ensure the longevity and reliability of the steel in the chemical industry. 5. Resistance to pitting and crevice corrosion: Special steel should be resistant to pitting and crevice corrosion, which can occur in areas of the steel that are exposed to stagnant or low-velocity corrosive media. Pitting and crevice corrosion can lead to localized damage and failure of the steel, so resistance to these types of corrosion is essential. 6. Low impurity content: Special steel used in the chemical industry should have low impurity content to minimize the risk of contamination of the chemicals being processed. Impurities can react with the chemicals or cause unwanted reactions, potentially leading to product quality issues or safety hazards. 7. Easy cleanability: The steel should have a smooth surface and be easily cleanable to prevent the buildup of contaminants or fouling. This is important to maintain the purity of the chemicals being processed and to ensure efficient operation of the equipment. Meeting these specific requirements ensures that special steel used in the chemical industry can withstand the harsh conditions and corrosive environments encountered, while maintaining its structural integrity, performance, and safety.

- Q: How is special steel used in the packaging industry?

- Special steel is used in the packaging industry to create durable, corrosion-resistant, and high-strength packaging materials. It is commonly used for manufacturing metal cans, drums, containers, and closures, ensuring the safe storage and transportation of various products, including food, chemicals, and hazardous materials. The unique properties of special steel make it an ideal choice for packaging applications as it enhances the strength, longevity, and protection of the packaging, ultimately ensuring the quality and integrity of the goods being packaged.

Send your message to us

Steel Rebar Production Line

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords