Steel IPE Heavy Weight I Beam in Europe Standard En10025 S235JR

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel IPE Description:

Steel IPE is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Steel IPE is usually made of structural steel and is used in construction and civil engineering. The steel IPE resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Steel IPE theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel IPE Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Steel IPE Images:

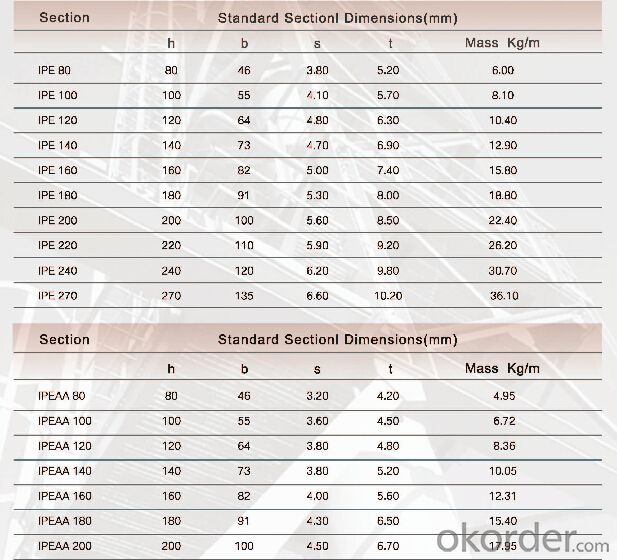

4. Steel IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: Can steel I-beams be used in the construction of residential homes?

- Yes, steel I-beams can be used in the construction of residential homes. Steel I-beams are often used in residential construction for their strength and durability. They are commonly used as load-bearing supports for walls, floors, and roofs. Steel I-beams offer several advantages over traditional wood or concrete beams, including greater strength-to-weight ratio, resistance to warping or twisting, and the ability to span longer distances without the need for additional support columns. Additionally, steel I-beams are fire-resistant, termite-resistant, and can withstand extreme weather conditions, making them a suitable choice for residential construction. However, it is important to consult with a structural engineer or architect to determine the appropriate size and specifications of steel I-beams based on the specific requirements of the residential home.

- Q: Can steel I-beams be used for industrial warehouses or storage facilities?

- Yes, steel I-beams can be used for industrial warehouses or storage facilities. Steel I-beams are commonly used in the construction of such structures due to their strength, durability, and load-bearing capabilities. They provide structural support and can withstand heavy loads, making them suitable for large-scale warehouses or storage facilities. Additionally, steel I-beams are versatile and can be customized to meet specific design requirements, making them a popular choice in the industrial construction industry.

- Q: What are the different methods of inspecting steel I-beams for defects or damage?

- There are several methods available for inspecting steel I-beams for defects or damage. These include visual inspection, ultrasonic testing, magnetic particle testing, dye penetrant testing, and radiographic testing. Visual inspection involves physically examining the beam for any visible signs of cracks, corrosion, or other abnormalities. Ultrasonic testing uses sound waves to detect internal flaws by measuring the time it takes for the waves to bounce back. Magnetic particle testing and dye penetrant testing are techniques used to identify surface cracks and discontinuities by applying magnetic particles or dye to the surface and observing any indications. Lastly, radiographic testing involves using X-rays or gamma rays to create an image of the beam, allowing for the detection of internal defects or damage.

- Q: What is the cost of steel I-beams compared to other structural materials?

- The cost of steel I-beams compared to other structural materials can vary depending on several factors. Generally, steel I-beams tend to be more expensive than materials like wood or concrete. However, when compared to other steel structural materials, such as steel tubes or columns, I-beams may be more cost-effective. The price of steel I-beams is influenced by various factors, including the size and weight of the beam, the grade of steel used, and market conditions. Larger and heavier I-beams will generally have a higher cost, as they require more raw materials and production processes. The grade of steel used can also affect the price, with higher-grade steels typically commanding a higher cost due to their enhanced strength and durability. Moreover, market conditions play a significant role in determining the cost of steel I-beams. Fluctuations in the availability and demand for steel can impact the price. For instance, during periods of high demand or shortages, the cost of steel I-beams may increase. On the other hand, during periods of low demand or oversupply, prices may be more competitive. It is important to consider that while steel I-beams may have a higher upfront cost compared to other materials, they offer numerous advantages that make them a preferred choice for many construction projects. Steel I-beams are known for their exceptional strength-to-weight ratio, durability, and versatility. They can withstand heavy loads, provide long-term structural integrity, and require minimal maintenance. These benefits often offset the initial cost and make steel I-beams a cost-effective choice in the long run. Ultimately, the cost of steel I-beams compared to other structural materials will depend on various factors, including size, grade, market conditions, and the specific needs of the project. It is advisable to consult with a construction professional or supplier to obtain accurate and up-to-date pricing information for a specific application.

- Q: What are the different grades of steel used in manufacturing I-beams?

- There are several different grades of steel commonly used in the manufacturing of I-beams. These grades include A36, A572, A992, and A588. A36 steel is the most commonly used grade for I-beams due to its strength and versatility. It has a minimum yield strength of 36,000 psi and a minimum tensile strength of 58,000-80,000 psi. A36 steel is often used in construction and structural applications. A572 steel is another popular grade for I-beams, particularly in the construction industry. It has a minimum yield strength of 50,000 psi and a minimum tensile strength of 65,000-85,000 psi. A572 steel is known for its high strength and excellent weldability. A992 steel is a relatively new grade that has become increasingly popular in recent years. It has a minimum yield strength of 50,000 psi and a minimum tensile strength of 65,000-85,000 psi. A992 steel offers improved strength and durability compared to A36 and A572, making it suitable for a wide range of applications. A588 steel is a high-strength, low-alloy grade commonly used in structural applications such as bridges and buildings. It has a minimum yield strength of 50,000 psi and a minimum tensile strength of 70,000-95,000 psi. A588 steel is known for its corrosion resistance and can withstand harsh environmental conditions. Overall, the choice of steel grade for manufacturing I-beams depends on the specific requirements of the project, including strength, durability, and corrosion resistance.

- Q: How much weight can I hold for No. 30 I-beam?

- This is calculated, in fact, the actual load-bearing area should be in the distance between the iron pipe, 12/5, 3 meters apart According to the interval of 4 meters, 30# I-beam is divided into 32A and 32C two, bearing respectively 9.7T and 10.6T, that is, each two supporting iron pipe can load 9.7 tons.

- Q: What are the load-bearing capacity of rectangular and I-beam steel sections of the same size?

- Therefore, if the stability is not considered, the bearing capacity of I-beam is large.But the stability of the rectangular steel is better, it is not easy to lose stability.

- Q: Help: how can I sample steel beams?

- The position of sampling and sampling reinforced standards like 50Cm after the number of interception head, pull a size of 40Cm and 35Cm, to cut a four molecular beam interception.

- Q: What are the considerations for steel I-beam design in high-wind speed areas?

- Some key considerations for steel I-beam design in high-wind speed areas include selecting the appropriate size and shape of the beam to withstand the wind loads, ensuring proper connections and fastening methods to maintain structural integrity, accounting for potential vibration and resonance effects, and implementing adequate bracing and reinforcement measures to enhance the beam's resistance against wind-induced forces. Additionally, the design should comply with local building codes and regulations specific to high-wind regions.

- Q: How do steel I-beams perform in terms of fatigue resistance?

- Steel I-beams possess outstanding properties when it comes to fatigue resistance. The design and construction of these I-beams render them highly resistant to fatigue failure, which refers to the gradual deterioration and eventual collapse of a material under repeated cyclic loading. The structural shape of I-beams, featuring flanges that resist bending and a web that resists shear forces, aids in distributing the load uniformly across the beam. This even distribution of the load minimizes stress concentrations and prevents the formation of fatigue cracks. Furthermore, steel itself is renowned for its elevated fatigue strength. It can endure a significant number of load cycles before succumbing to failure, making it an ideal material for situations where fatigue resistance is of utmost importance. Steel I-beams are widely employed in various structural applications such as bridges, buildings, and industrial facilities, where they encounter repeated and fluctuating loads. The fatigue resistance of steel I-beams guarantees their long-term structural integrity and safety under these demanding conditions. Moreover, the fatigue performance of steel I-beams can be enhanced through a variety of techniques, including surface treatments and welding details. These methods aim to improve the fatigue life and durability of the beams by reducing stress concentrations and increasing their resistance to the initiation and propagation of cracks. All in all, steel I-beams exhibit remarkable fatigue resistance, making them a dependable choice for structures that require long-lasting durability and safety. Their ability to withstand cyclic loading and fend off fatigue failure makes them ideal for applications where repeated or fluctuating loads are anticipated.

Send your message to us

Steel IPE Heavy Weight I Beam in Europe Standard En10025 S235JR

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords