Steel Frame SF140 for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

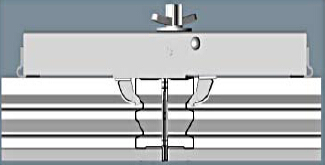

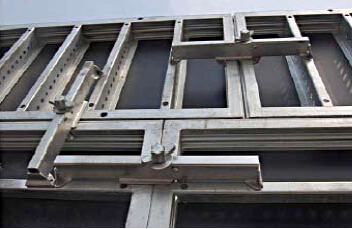

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How is steel formwork installed?

- Accurate and sturdy construction is ensured through the systematic and efficient installation of steel formwork. The typical process involves the following steps: 1. Careful planning and preparation are essential before steel formwork installation. This includes determining the desired shape and dimensions of the concrete structure, calculating the required amount of steel formwork panels and accessories, and ensuring the availability of all necessary tools and equipment. 2. Adequate site preparation is necessary. This involves clearing the construction site of debris and obstacles, leveling the ground, and establishing a solid foundation. 3. The positioning and alignment of steel formwork panels are carried out according to the planned structure. Various methods, such as clamps, nuts, bolts, or pins, are used to connect and secure the panels. Proper alignment and tightness are crucial to prevent concrete leakage or seepage. 4. If necessary, steel reinforcement bars are installed within the formwork to provide additional strength and support to the concrete structure. These reinforcement bars are precisely placed and firmly secured to the formwork panels in accordance with the structural design. 5. Adequate bracing of the formwork is essential to ensure stability and prevent deformation during concrete pouring and curing. Horizontal and vertical bracing systems are utilized to provide the necessary support and rigidity, evenly distributing the load and maintaining the desired shape of the structure. 6. Concrete is poured into the securely placed and braced steel formwork. Vibrators or other suitable equipment are used to compact the concrete, eliminating air bubbles and promoting proper adhesion and density. 7. After pouring and compacting the concrete, it must be cured to achieve maximum strength and durability. Curing can be done using various methods, such as covering the structure with plastic sheets or water spraying. Once the concrete has sufficiently cured, the steel formwork can be carefully removed, starting from the top and gradually moving downwards. It is important to note that the installation process may vary depending on project requirements, the complexity of the structure, and the type of steel formwork used. Therefore, it is advisable to consult experienced professionals or engineers to ensure proper installation and adherence to safety standards.

- Q: What are the different types of steel formwork available?

- There are several types of steel formwork available in the construction industry, each with its own unique features and advantages. Some of the most common types include: 1. Modular steel formwork: This type of formwork consists of prefabricated steel panels that can be assembled and disassembled easily. It is customizable and can be used for various shapes and sizes of concrete structures. 2. Tunnel formwork: As the name suggests, tunnel formwork is used for constructing tunnels and underground structures. It is made of steel plates and is designed to withstand high pressure and provide a smooth finish to the concrete. 3. Climbing formwork: This type of formwork is used for tall structures like skyscrapers. It is designed to be lifted and moved vertically as the construction progresses. Climbing formwork provides safety and efficiency while constructing multi-story buildings. 4. Steel soldier formwork: This is a versatile and cost-effective type of formwork that is commonly used for walls and columns. It is made of steel beams and soldiers and can be easily adjusted to different heights and widths. 5. Steel frame formwork: This type of formwork is made of steel frames with plywood or metal panels attached to it. It is lightweight, easy to handle, and provides a smooth finish to the concrete. 6. Steel table formwork: This is a type of formwork that is used for large horizontal slabs. It consists of steel tables that are supported by props or scaffolding. Steel table formwork is quick to assemble and dismantle, making it ideal for projects with tight timelines. These are just a few examples of the different types of steel formwork available. The choice of formwork depends on the specific requirements of the construction project, such as the type of structure, load-bearing capacity, and desired finish.

- Q: Can steel formwork be used for tall structures?

- Yes, steel formwork can be used for tall structures. Steel is a strong and durable material that can withstand the weight and pressure of concrete. It offers the necessary stability and support required for constructing tall buildings and structures. Additionally, steel formwork is versatile, allowing for flexibility in design and construction.

- Q: What are the different types of steel used in formwork construction?

- There are several types of steel commonly used in formwork construction, including mild steel, high-strength low-alloy steel (HSLA), and high-strength steel. Additionally, stainless steel may be utilized in specific applications where corrosion resistance is required. The choice of steel type depends on factors such as the desired strength, durability, and cost-effectiveness of the formwork system.

- Q: How does steel formwork contribute to the overall durability of a structure?

- Steel formwork contributes to the overall durability of a structure by providing a strong and rigid framework during the concrete pouring process. It ensures accurate and precise shaping of the concrete, resulting in a solid and uniform structure. Steel formwork is highly resistant to warping, bending, and cracking, making it more durable than other types of formwork materials. Its strength and durability allow for multiple reuse, reducing construction costs and minimizing waste. Additionally, steel formwork provides excellent support for the concrete as it cures, preventing any deformation or collapse. Overall, steel formwork plays a crucial role in enhancing the longevity and robustness of a structure.

- Q: How does steel formwork affect the overall seismic performance of a structure?

- Steel formwork can significantly affect the overall seismic performance of a structure in several ways. Firstly, steel formwork provides a rigid and robust temporary support system during the construction process. It ensures proper alignment and placement of concrete, which is crucial for the structural integrity of the building. By providing accurate and precise formwork, steel helps in creating a well-designed structure that can withstand seismic forces. Secondly, steel formwork enhances the strength and stiffness of the concrete structure. Steel is known for its high tensile strength, which allows it to resist the lateral forces induced by an earthquake. This increased strength and stiffness can help in reducing the deformation and damage caused by seismic activities. Additionally, steel formwork can prevent the formation of cracks and improve the overall durability of the structure. Moreover, steel formwork can contribute to the ductility of a building. Ductility is the ability of a structure to undergo large deformations without sudden failure. Steel formwork allows for the creation of reinforced concrete elements, such as beams and columns, which can absorb and dissipate seismic energy through plastic deformations. This plastic behavior helps in redistributing the seismic forces and reducing the overall vulnerability of the structure. Furthermore, steel formwork can facilitate the use of innovative structural systems like steel plate shear walls, moment frames, or braced frames. These systems are designed to provide enhanced seismic resistance by dissipating energy and controlling the deformations during an earthquake. Steel formwork allows for the precise fabrication and installation of these systems, ensuring their effectiveness in improving the seismic performance of the structure. In conclusion, steel formwork plays a crucial role in enhancing the overall seismic performance of a structure. It provides temporary support, enhances the strength and stiffness of concrete, improves ductility, and enables the use of innovative seismic-resistant systems. By incorporating steel formwork in the construction process, engineers can create structures that are better able to withstand the destructive forces of earthquakes.

- Q: How does steel formwork affect the overall construction productivity?

- Steel formwork can significantly enhance overall construction productivity. It offers greater strength and durability compared to traditional formwork materials, allowing for faster and more efficient construction processes. Due to its reusable nature, steel formwork eliminates the need for constant replacement, reducing downtime and material costs. Additionally, its modular design enables easy assembly and disassembly, enabling faster construction cycles. The precision and accuracy of steel formwork also contribute to improved quality control, resulting in higher productivity and reduced rework.

- Q: Are there any fire safety considerations when using steel formwork?

- Yes, there are fire safety considerations when using steel formwork. Steel is a non-combustible material, which means it does not catch fire or contribute to the spread of flames. However, during a fire, steel can lose its structural integrity and collapse more rapidly than other materials. Therefore, it is important to have proper fire protection measures in place, such as fire-resistant coatings or fireproofing materials, to ensure the safety of personnel and the structure when using steel formwork.

- Q: What are the different types of coatings used on steel formwork?

- Steel formwork can be protected and its performance enhanced through the use of various types of coatings. These coatings are typically applied to the steel surface to prevent corrosion, increase durability, and improve the overall appearance of the formwork. One commonly used coating for steel formwork is epoxy. Epoxy coatings are recognized for their excellent resistance to chemicals, abrasion, and impact. They create a hard, smooth, and long-lasting surface that can withstand harsh environments and heavy usage. Additionally, epoxy coatings adhere well to the steel surface, ensuring long-term protection against corrosion. Another frequently employed coating for steel formwork is galvanizing. Galvanizing involves applying a zinc layer to the steel surface through hot-dip galvanization. This coating provides exceptional corrosion resistance and helps prolong the formwork's lifespan. Galvanized coatings are particularly suitable for formwork utilized in outdoor or marine environments where exposure to moisture and severe weather conditions is expected. Polyurethane coatings are also utilized on steel formwork to offer high levels of protection and durability. These coatings exhibit outstanding resistance to chemicals, abrasion, and UV radiation, making them ideal for formwork used in construction projects where exposure to harsh elements is common. Furthermore, polyurethane coatings provide a smooth and glossy finish, enhancing the formwork's appearance. Apart from these coatings, there are numerous other types available, such as acrylic coatings, polyester coatings, and powder coatings. Acrylic coatings are known for their strong adhesion and resistance to weather conditions, while polyester coatings offer excellent durability and chemical resistance. On the other hand, powder coatings are applied electrostatically and deliver a highly protective and decorative finish. Ultimately, the choice of coating for steel formwork depends on the specific requirements of the project, including anticipated environmental conditions, desired durability, and aesthetic preferences. It is crucial to carefully consider the properties and advantages of each coating type to ensure that the formwork is adequately protected and performs optimally throughout its lifespan.

- Q: Is steel formwork suitable for projects with high concrete temperature requirements?

- Yes, steel formwork is suitable for projects with high concrete temperature requirements. Steel has excellent heat resistance properties, making it ideal for withstanding high temperatures during the curing process of concrete. Additionally, steel formwork is durable, strong, and can be reused multiple times, making it a cost-effective choice for such projects.

Send your message to us

Steel Frame SF140 for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords