Protection Platform for Formwork and Scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

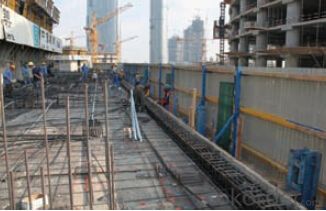

Protection Platform PP-50

A kind of new type construction protection system, applying operating platform and safer job

location for construction corps.

Characteristics:

◆ Easy and quick assembling.

◆ Lifted as a group, it is rapid and economic.

◆ Auto-climbing

◆ A safe and reliable anchor system

1. Composition

2. Assembly process of anchor system

(1) Embed V-climbing cone and anchor plate into the slab.

(2) Fix anchor shoe on the slab by tensile bolt.

(3) The fixed anchor shoe.

◆ High work efficiency with work platform and unload platform

◆ High light transmittance with the hollow block

- Q: Can steel formwork be used for precast concrete wall panels?

- Yes, steel formwork can be used for precast concrete wall panels. Steel formwork offers several advantages for precast concrete construction. It provides high strength, durability, and dimensional accuracy, ensuring that the wall panels are of high quality. Steel formwork can easily be reused multiple times, making it a cost-effective option. It also allows for quick and efficient installation, reducing construction time. The flexibility of steel formwork enables the creation of various shapes and sizes of wall panels, meeting the design requirements of different projects. Overall, steel formwork is a suitable choice for precast concrete wall panels, offering numerous benefits in terms of strength, durability, efficiency, and cost-effectiveness.

- Q: Can steel formwork be used for airport construction projects?

- Yes, steel formwork can be used for airport construction projects. Steel formwork is known for its strength, durability, and ability to withstand heavy loads and harsh weather conditions, making it a suitable choice for large-scale projects such as airports. Additionally, steel formwork provides excellent quality and precision in concrete construction, ensuring the required high standards for airport infrastructure.

- Q: How does steel formwork affect the overall construction site logistics?

- The overall construction site logistics can be significantly impacted by steel formwork. Firstly, the durability and strength of steel formwork allow for multiple reuses, reducing the need for constant replacement and disposal of materials. This results in reduced waste generation and improved site cleanliness. Moreover, steel formwork is lightweight and easily adjustable, making it easier to handle and transport around the construction site. This improves material handling efficiency and reduces the time required for installation and removal of formwork. Additionally, the lightweight nature of steel formwork reduces the load on the structure, leading to reduced transportation costs and improved safety during construction. Furthermore, steel formwork offers high dimensional accuracy, ensuring precise and consistent shapes for concrete elements. This helps streamline the construction process by reducing the need for excessive adjustments and rework, resulting in improved time management and increased productivity. Additionally, steel formwork provides a smooth and even finish to concrete structures, eliminating the need for additional surface treatments and reducing the time and effort required for finishing work. In summary, steel formwork contributes to improved construction site logistics by reducing waste, enhancing material handling efficiency, improving construction speed, and ensuring high-quality finishes. Its durability, lightweight nature, and dimensional accuracy make it a valuable asset in optimizing construction processes and achieving project timelines more effectively.

- Q: Can steel formwork be used for different types of concrete finishes?

- Yes, steel formwork can be used for different types of concrete finishes. Steel formwork is highly versatile and can be customized to create various concrete finishes such as smooth, textured, or patterned surfaces. The steel formwork allows for precise shaping and molding of the concrete, enabling the creation of different finishes according to the desired design and aesthetic requirements. Additionally, steel formwork can be easily adjusted and reused for different projects, making it a cost-effective choice for achieving diverse concrete finishes.

- Q: How does steel formwork compare to wooden formwork in terms of cost?

- Steel formwork is generally more expensive than wooden formwork. However, it offers longer durability and can be reused multiple times, reducing the overall cost in the long run. Additionally, steel formwork provides better accuracy and stability, resulting in improved quality of construction.

- Q: What are the different sizes and dimensions of steel formwork?

- The sizes and dimensions of steel formwork can vary depending on the specific requirements of the construction project. However, common sizes range from 1.2 meters to 2.4 meters in width and 2.4 meters to 4.8 meters in length. The thickness of the steel sheets used for formwork can also vary, typically ranging from 3mm to 6mm.

- Q: How does steel formwork handle different concrete pumping methods?

- Steel formwork is highly versatile and can handle different concrete pumping methods with ease. The rigid and sturdy nature of steel formwork allows it to withstand the pressure and force exerted by various pumping techniques such as boom pumps, line pumps, and even placing concrete by gravity. Additionally, the smooth surface of steel formwork ensures that the concrete flows smoothly during the pumping process, resulting in a consistent and high-quality finish. Overall, steel formwork is well-suited for accommodating different concrete pumping methods and ensuring efficient and successful construction projects.

- Q: How does steel formwork contribute to improved construction site logistics?

- Steel formwork contributes to improved construction site logistics in several ways. First and foremost, steel formwork is durable and reusable, which reduces the need for frequent replacement and disposal. This leads to significant cost savings and reduces the amount of waste generated on the construction site. Additionally, steel formwork is highly versatile and can be easily customized to meet specific project requirements. This flexibility allows for efficient and precise construction, resulting in improved productivity and reduced construction time. With steel formwork, construction site activities can be streamlined, making it easier to manage and coordinate various tasks. Furthermore, steel formwork provides enhanced safety on construction sites. Its sturdy and rigid structure ensures stability during concrete pouring and curing processes, minimizing the risk of accidents or structural failures. This results in a safer working environment for construction workers and reduces the likelihood of delays or disruptions caused by safety issues. Moreover, steel formwork offers better control over the quality of the concrete structure being built. Its smooth surface and accurate dimensions help achieve consistent and precise finishes. This reduces the need for rework or corrections, saving time and reducing material wastage. Lastly, steel formwork is easy to handle and transport due to its lightweight nature compared to traditional timber formwork. This simplifies logistics planning and allows for faster and more efficient movement of formwork components across the construction site. The ease of handling also reduces the physical strain on workers, leading to increased productivity and reduced risk of injuries. In conclusion, steel formwork contributes to improved construction site logistics by offering durability, versatility, safety, quality control, and ease of handling. These benefits contribute to cost savings, reduced waste, enhanced productivity, and a safer working environment, ultimately leading to more efficient and successful construction projects.

- Q: How does steel formwork compare to plastic formwork in terms of cost and durability?

- Steel formwork is generally more expensive than plastic formwork in terms of upfront cost. The cost of steel formwork includes the cost of material, fabrication, and transportation, which can be higher compared to plastic formwork. On the other hand, plastic formwork is relatively cheaper due to its lower material and production costs. However, when it comes to durability, steel formwork has a significant advantage. Steel is known for its strength and durability, making it capable of withstanding heavy loads and repeated use over time. It is resistant to wear and tear, deformation, and damage caused by external factors such as weather conditions or mishandling. This durability ensures that steel formwork can be reused multiple times, resulting in cost savings in the long run. Plastic formwork, while cost-effective initially, may have limitations in terms of durability. Plastic is not as strong as steel and may be prone to deformation or cracking, especially under heavy loads or if not handled properly. Although plastic formwork can still be reused multiple times, it may require more frequent replacement or repair compared to steel formwork. In summary, steel formwork may be more expensive initially but offers superior durability and longevity. Plastic formwork, on the other hand, is cheaper but may not withstand heavy loads or repeated use as effectively as steel. The choice between the two depends on the specific project requirements, budget constraints, and the expected lifespan of the formwork.

- Q: What are the advantages of using steel formwork?

- There are several advantages of using steel formwork. Firstly, steel formwork is highly durable and can withstand multiple uses, making it cost-effective in the long run. Secondly, it provides a smooth and consistent finish to the concrete structure, resulting in high-quality construction. Additionally, steel formwork is lightweight and easy to handle, which reduces labor and transportation costs. It also offers flexibility in terms of design modifications and can be easily assembled and dismantled. Lastly, steel formwork is fire-resistant and offers better safety measures compared to other formwork materials.

Send your message to us

Protection Platform for Formwork and Scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords