Steel Frame Corner-Link for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

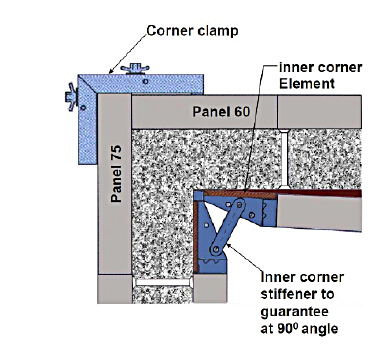

◆ The selection of panels.

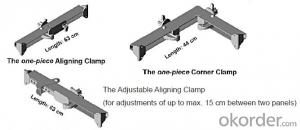

◆ Kinds of panel connectors.

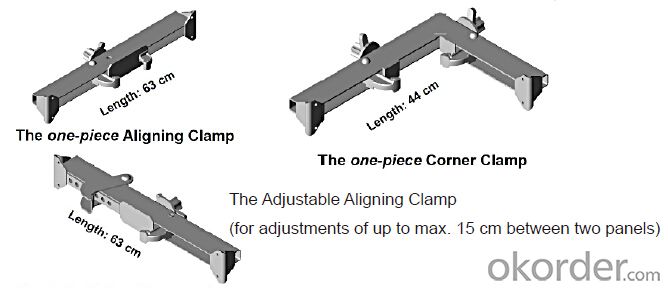

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork improve the quality of concrete structures?

- Steel formwork is widely employed in the construction industry due to its numerous advantages, which greatly enhance the quality of concrete structures. Here are several ways in which steel formwork improves the quality of concrete structures: 1. Superior Form Stability: Compared to traditional wooden formwork, steel formwork offers enhanced form stability. It is more rigid and less prone to warping or distortion, guaranteeing that the concrete is poured into an accurate and consistent shape. This results in straighter walls, smoother surfaces, and overall better structural integrity. 2. Increased Durability: Steel formwork is highly durable and capable of withstanding the harsh conditions of construction sites. Unlike wooden formwork, it does not rot, decay, or easily sustain damage. Its long lifespan allows for multiple reuses, thereby reducing costs and waste. This durability translates into stronger and longer-lasting concrete structures. 3. Precise Dimensions: Steel formwork is manufactured with high precision, enabling accurate and consistent dimensions in concrete structures. It facilitates achieving the desired shape, size, and alignment of elements. This accuracy is crucial in ensuring that the structure meets required specifications and architectural designs, resulting in a high-quality finished product. 4. Improved Surface Finish: Steel formwork provides a smooth and even surface finish to concrete structures. The design of steel panels minimizes surface imperfections and prevents leakage of the concrete mixture. This results in visually appealing structures with uniform finishes, which reduces the need for additional plastering or finishing work. 5. Enhanced Safety: Steel formwork enhances safety during the construction process. Its sturdy and rigid nature provides a stable platform for workers to pour and work with concrete. The risk of accidents, such as formwork failure or collapse, is significantly reduced with steel formwork, ensuring the safety of workers and the integrity of the structure. In conclusion, the utilization of steel formwork in concrete construction brings multiple benefits that contribute to the improvement of structure quality. With its form stability, durability, precise dimensions, improved surface finish, and enhanced safety, steel formwork plays a vital role in ensuring the integrity, aesthetics, and longevity of concrete structures.

- Q: How does steel formwork handle concrete pouring and consolidation?

- Steel formwork is a popular choice for concrete pouring and consolidation due to its strength, durability, and ease of use. When it comes to handling concrete pouring and consolidation, steel formwork offers several advantages. Firstly, steel formwork provides a solid and rigid structure that can withstand the pressure exerted by the weight of the concrete. This ensures that the formwork remains stable throughout the pouring and consolidation process, preventing any deformations or collapses that could compromise the quality of the concrete structure. Additionally, steel formwork is highly resistant to moisture and chemicals present in the concrete mix, which helps to maintain its integrity and durability. This resistance ensures that the formwork does not get damaged or corroded during the pouring and consolidation process, thereby prolonging its lifespan and reducing maintenance costs. Moreover, steel formwork allows for efficient and precise concrete placement and consolidation. The smooth surfaces of steel formwork facilitate the easy flow and distribution of the concrete, ensuring that it fills all the required areas evenly. This helps to eliminate voids and air pockets, resulting in a denser and more structurally sound concrete structure. Furthermore, steel formwork can be easily adjusted and customized to meet specific project requirements. Its modular nature allows for easy assembly and disassembly, making it a cost-effective choice for various construction projects. The flexibility of steel formwork also allows for the creation of complex shapes and designs, enabling architects and engineers to realize their creative visions. In conclusion, steel formwork is an ideal choice for handling concrete pouring and consolidation due to its strength, durability, and versatility. It provides a stable and robust structure that can withstand the weight and pressure of the concrete, while also ensuring efficient and precise placement and consolidation. These qualities make steel formwork a reliable and practical solution for a wide range of construction projects.

- Q: Can steel formwork be used in hotel or hospitality construction projects?

- Yes, steel formwork can be used in hotel or hospitality construction projects. Steel formwork offers several advantages over other types of formwork, such as wood or concrete. Firstly, steel formwork is highly durable and can withstand the heavy loads and pressures associated with construction projects. This makes it suitable for use in the construction of hotels, which often require large and complex structures. Secondly, steel formwork is reusable, which can result in cost savings and reduced construction time. This is particularly beneficial for hotel or hospitality construction projects, where the construction process needs to be efficient and timely. Additionally, steel formwork provides a smooth and high-quality finish to concrete surfaces, which is important in the hotel and hospitality industry where aesthetics play a significant role. The smooth finish of steel formwork can enhance the overall appearance of the hotel, creating a more visually appealing and luxurious environment for guests. Furthermore, steel formwork allows for greater flexibility in design, as it can be easily shaped and adjusted to meet specific project requirements. This is advantageous in hotel or hospitality construction projects, where unique and customized designs are often desired to create a distinctive and memorable guest experience. In conclusion, steel formwork can indeed be used in hotel or hospitality construction projects due to its durability, reusability, ability to provide a smooth finish, and flexibility in design.

- Q: How does steel formwork impact the overall sustainability of a project?

- Steel formwork can have a significant impact on the overall sustainability of a project. Firstly, steel is a highly durable material that can withstand repeated use, which means that steel formwork can be reused multiple times before reaching the end of its life cycle. This reusability reduces the need for frequent replacements, minimizing the consumption of materials and the waste generated during construction. Additionally, steel formwork is known for its strength and structural stability, allowing for the construction of robust and long-lasting structures. This means that buildings constructed with steel formwork are more likely to have a longer lifespan, reducing the need for frequent renovations or demolitions. Consequently, this leads to a decrease in the consumption of resources and the associated carbon emissions that come with new construction. Moreover, steel is a highly recyclable material, and steel formwork can be easily recycled at the end of its life cycle. The recycling process of steel requires less energy compared to the production of new steel, thereby reducing the carbon footprint of a project. By choosing steel formwork, construction projects can contribute to the circular economy by promoting the use of recycled materials and reducing landfill waste. Furthermore, steel formwork offers enhanced efficiency in construction processes. Its modular nature and ease of assembly make it a time-saving option, reducing construction time and, consequently, the energy consumption required for on-site operations. The accelerated construction process also minimizes disruption to the surrounding environment, reducing the overall environmental impact of the project. Lastly, steel formwork can contribute to the overall sustainability of a project by providing a safer working environment for construction workers. Its strength and stability ensure that the formwork remains secure during concrete pouring, minimizing the risk of accidents and injuries. This promotes the well-being of workers and aligns with the principles of social sustainability. In conclusion, steel formwork positively impacts the overall sustainability of a project by minimizing material consumption, reducing waste generation, promoting recycling, enhancing construction efficiency, and providing a safer working environment. Its durability, reusability, and recyclability contribute to the conservation of resources, reduction of carbon emissions, and long-term viability of structures. By opting for steel formwork, construction projects can advance sustainability goals and contribute to a more environmentally and socially responsible built environment.

- Q: How do steel formwork systems differ from one another?

- There are several ways in which steel formwork systems can vary from one another. Firstly, their design and construction can be different. Certain systems are modular and consist of pre-assembled panels that can be easily connected and adjusted to create various shapes and sizes. On the other hand, there are custom-made systems that are specifically tailored for particular projects, offering more flexibility in formwork design. Secondly, the strength and durability of steel formwork systems can differ. Some systems are engineered to withstand heavy loads and extreme conditions, making them suitable for large-scale construction projects. Conversely, there are lighter and more portable systems that are better suited for smaller projects or areas with limited access. Another aspect that sets steel formwork systems apart is their user-friendliness. Some systems are designed to be easy to use, with built-in handles, adjustable brackets, and user-friendly locking mechanisms. These features allow for quick and efficient installation and dismantling, saving time and effort on the construction site. Furthermore, steel formwork systems can offer different finishing options. Some provide smooth and precise finishes, which are ideal for projects that require a high-quality surface. Others have textured or patterned finishes, adding a decorative element to the concrete structure. Lastly, steel formwork systems can vary in terms of their cost and availability. Some systems are more affordable and readily available, making them a popular choice for smaller projects or contractors on a tight budget. On the other hand, there are systems that are more expensive or require longer lead times for fabrication, but offer advanced features or customization options. In conclusion, the distinctions between steel formwork systems lie in their design, strength, ease of use, finishing options, and cost. Contractors and construction professionals should carefully assess these factors to choose the most suitable steel formwork system for their specific project requirements.

- Q: How does steel formwork handle formwork stripping time?

- Steel formwork is known for its durability and strength, which allows for efficient and quick formwork stripping. Unlike other materials like wood or plastic, steel formwork does not deform or warp under pressure, ensuring that it can be removed easily and without any damage to the concrete structure. Additionally, steel formwork systems are designed with quick-release mechanisms and adjustable components, allowing for faster and more straightforward formwork stripping. Overall, steel formwork significantly reduces formwork stripping time and increases productivity in construction projects.

- Q: How does steel formwork contribute to the quality of the concrete finish?

- The quality of the concrete finish is greatly influenced by the use of steel formwork. The primary role of steel formwork is to provide a sturdy and inflexible structure that holds the concrete in place while it is being poured and cured. This effectively prevents any movement or distortion of the concrete, resulting in a sleek and uniform surface. Furthermore, steel formwork offers superior dimensional stability compared to other materials used for formwork. It does not bend or alter under the pressure of the wet concrete, guaranteeing precise and consistent shapes and measurements. This is particularly crucial for structures that demand accurate dimensions, such as beams, columns, or walls. Additionally, steel formwork allows for better control over the final appearance of the concrete surface. The smooth and non-porous nature of steel minimizes the likelihood of air bubbles or voids forming on the surface, resulting in an aesthetically pleasing finish with fewer imperfections. Moreover, steel formwork exhibits exceptional resistance to moisture and chemicals found in the concrete mixture. This prevents any damage or deterioration of the formwork itself, ensuring a clean and unblemished concrete surface. It also enables easy removal of the formwork once the concrete has cured, leaving no residues or marks behind. Lastly, the reusability of steel formwork makes it a cost-effective and sustainable choice. By being able to reuse the same set of formwork multiple times, consistent quality is achieved in subsequent concrete pours. This eliminates the need for frequent investments in new formwork materials, reducing overall project costs and environmental impact. In conclusion, the use of steel formwork is vital for achieving a high-quality concrete finish. Its strength, dimensional stability, control over surface finish, resistance to moisture and chemicals, and reusability all contribute to a smooth, accurate, and visually appealing surface while providing durability and cost-effectiveness to construction projects.

- Q: Can steel formwork withstand extreme weather conditions?

- Yes, steel formwork is designed to withstand extreme weather conditions. Steel is known for its strength and durability, making it highly resistant to harsh weather elements such as heavy rain, strong winds, and high temperatures. Additionally, steel formwork is often treated with protective coatings to further enhance its resistance to corrosion and degradation caused by extreme weather conditions.

- Q: How does steel formwork handle extreme weather conditions?

- Steel formwork excels in durability, effortlessly enduring even the harshest weather conditions. Its robustness and resilience render it appropriate for deployment in diverse climates, ranging from scorching and muggy to frigid and snowy. Under intense heat, steel formwork remains stable, steadfastly avoiding warping or deformation. Its elevated melting point guarantees the preservation of its shape and structural integrity, even when confronted with extreme heat. Moreover, steel formwork is impervious to moisture absorption and expansion, thwarting any potential harm arising from expansion and contraction in arid and sweltering environments. In freezing temperatures, steel formwork remains impervious, imperviousness that precludes brittleness. It can endure the burden of snow loads without any peril of collapse. Furthermore, steel formwork prevents the absorption of moisture, effectively eliminating the risk of damage caused by freeze-thaw cycles. Additionally, steel formwork showcases resistance to corrosion, rendering it appropriate for employment in regions with high humidity or exposure to saltwater. Its corrosion resistance properties guarantee the formwork's tenacity and functionality, even when subjected to extreme weather conditions over extended periods. All in all, the ability of steel formwork to withstand extreme weather conditions stems from its exceptional strength, durability, and resistance to temperature variations, moisture, and corrosion. These attributes establish it as a dependable and long-lasting choice for construction ventures occurring in various climates worldwide.

- Q: How does steel formwork affect the overall aesthetics of a construction project?

- The overall aesthetics of a construction project can be significantly influenced by steel formwork. Unlike traditional timber formwork, steel formwork offers a modern and sleek look that enhances the visual appeal of a structure. The clean lines and smooth surfaces achieved with steel formwork give a building a polished and sophisticated appearance. Moreover, steel formwork allows for greater precision and accuracy in shaping concrete, resulting in a more seamless and uniform finish. This is particularly important in architectural designs that require intricate or complex shapes. By using steel formwork, the concrete is poured exactly as intended, resulting in a more visually appealing end result. Furthermore, steel formwork is highly durable and resistant to wear and tear. It does not warp or deform over time, maintaining its structural integrity and aesthetic appeal for a longer period. This durability contributes to the longevity and overall quality of a construction project, making it a more attractive investment for owners and potential buyers. Another advantage of steel formwork is its adaptability. Steel can be easily molded and shaped into various sizes and configurations, allowing for greater design flexibility. This versatility empowers architects and designers to create unique and eye-catching structures that stand out from the rest. In conclusion, the use of steel formwork in a construction project has a positive impact on its overall aesthetics. Its sleek appearance, precise shaping capabilities, durability, and design flexibility all contribute to a visually appealing end result. Steel formwork enhances the architectural design, creates a polished finish, and increases the longevity and value of the structure.

Send your message to us

Steel Frame Corner-Link for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords