Steel Frame Corner-Link for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

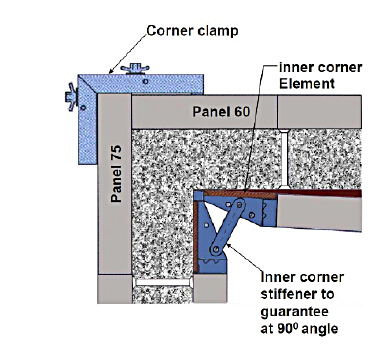

◆ The selection of panels.

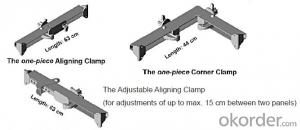

◆ Kinds of panel connectors.

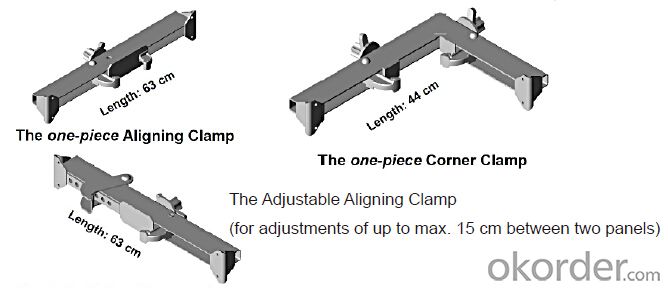

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: What are the considerations when designing steel formwork for columns?

- When designing steel formwork for columns, there are several important considerations that need to be taken into account. These considerations include the size and shape of the column, the load it will bear, the height of the column, the desired finish of the concrete, and the availability of labor and equipment. Firstly, the size and shape of the column will determine the dimensions and configuration of the formwork. The formwork needs to be designed to accommodate the specific dimensions of the column, including its diameter or width, and its height. The formwork may need to be adjustable or modular to accommodate different column sizes and shapes. Secondly, the load that the column will bear is an important consideration. The formwork needs to be designed to withstand the weight of the concrete, as well as any additional loads such as construction materials or equipment. It should be able to support the weight without deformation or failure, ensuring the integrity and safety of the structure. The height of the column also needs to be considered when designing the formwork. Tall columns may require additional supports or bracing to prevent buckling or collapsing. The formwork should be designed to provide adequate stability and strength throughout the height of the column. Moreover, the desired finish of the concrete is an essential consideration. If a smooth or architectural finish is desired, the formwork needs to be designed to provide a smooth and even surface. This may require the use of special form liners or coatings to achieve the desired finish. Lastly, the availability of labor and equipment should be taken into account. The design of the formwork should consider the ease of assembly, disassembly, and transportation. It should be practical and efficient to install and dismantle, taking into account the available labor and equipment on the construction site. In summary, when designing steel formwork for columns, considerations should include the size and shape of the column, the load it will bear, the height of the column, the desired finish of the concrete, and the availability of labor and equipment. By carefully considering these factors, the formwork can be designed to meet the specific requirements of the project, ensuring a safe and efficient construction process.

- Q: How does steel formwork accommodate for different concrete curing temperatures?

- Steel formwork is able to accommodate for different concrete curing temperatures due to its high thermal conductivity. This means that the steel transfers heat more efficiently, allowing for a faster and more uniform distribution of heat throughout the formwork. As a result, the concrete cures at a more consistent temperature, reducing the risk of uneven curing and potential structural issues. Additionally, steel formwork provides better insulation, preventing excessive heat loss or gain during the curing process, which further helps to maintain the desired temperature conditions.

- Q: How does steel formwork prevent concrete spalling?

- Steel formwork prevents concrete spalling by providing a strong and durable mold for the concrete to be poured into. The steel formwork holds the concrete in place during the curing process, preventing any movement or displacement that could lead to spalling. Additionally, the smooth surface of the steel formwork helps to create a uniform and even finish on the concrete, minimizing the risk of spalling.

- Q: Can steel formwork be used for infrastructure construction projects?

- Yes, steel formwork can be used for infrastructure construction projects. Steel formwork offers high strength, durability, and stability, making it suitable for constructing various types of infrastructure such as bridges, tunnels, dams, and highways. It can withstand heavy loads, provide smooth finish, and can be easily reused, making it a cost-effective choice for large-scale construction projects.

- Q: How does steel formwork contribute to the overall moisture resistance of the structure?

- In several ways, steel formwork plays a role in the overall moisture resistance of a structure. Firstly, its design focuses on high durability and resistance to corrosion. This means that it can endure exposure to moisture without deteriorating or compromising its structural integrity. Moreover, tight joints and connections are used in the construction of steel formwork to minimize the possibility of water infiltration. Unlike traditional timber formwork, steel formwork does not shrink or warp when exposed to moisture, guaranteeing the absence of gaps or openings that would allow water to seep into the structure. In addition, protective finishes such as epoxy or galvanized coatings are often applied to steel formwork, providing an additional layer of moisture resistance. These coatings act as a barrier, preventing water from seeping into the steel and reaching the concrete structure. Steel formwork ensures that moisture is prevented from entering the structure by providing a robust and watertight enclosure during the construction process. This is especially crucial for structures that will face external elements, such as bridges or buildings located in humid or rainy climates. In summary, steel formwork's durability, tight joints, and protective coatings contribute to the overall moisture resistance of a structure, ensuring that it remains structurally sound and free from water damage.

- Q: What are the different types of formwork ties used in steel formwork?

- There are several different types of formwork ties that are commonly used in steel formwork systems. These ties are essential for holding the formwork panels together and ensuring the stability and strength of the formwork structure. 1. Wedge Tie: This is the most common type of formwork tie used in steel formwork. It consists of a wedge-shaped metal piece that is inserted into a hole in the formwork panel. The wedge is then tightened, creating a strong connection and holding the panels in place. 2. Pin and Wedge Tie: This type of tie consists of a pin and a wedge. The pin is inserted into a hole in the formwork panel and then the wedge is driven into the pin, creating a tight connection. 3. Wing Nut and Tie Rod: This tie system uses a wing nut and a tie rod to hold the formwork panels together. The tie rod is threaded through the panels and secured with a wing nut on each side. This type of tie allows for easy removal and reassembly of the formwork. 4. Coil Tie: A coil tie is a type of tie that is used when the formwork panels need to be secured to the steel reinforcement bars. The tie is threaded through the formwork panel and then wrapped around the reinforcement bar, creating a secure connection. 5. Flat Tie: Flat ties are used to connect the formwork panels in situations where the panels need to be secured tightly against each other. These ties are flat metal strips that are inserted into holes in the formwork panels and then tightened. These are just a few examples of the different types of formwork ties used in steel formwork systems. The choice of tie will depend on factors such as the specific formwork design, the load requirements, and the ease of installation and removal. It is important to select the appropriate tie system to ensure the stability and safety of the formwork structure.

- Q: How does steel formwork contribute to the overall acoustics of the structure?

- Steel formwork does not directly contribute to the overall acoustics of a structure as its primary function is to provide support and shape during the construction process. The acoustics of a building are primarily influenced by the design and materials used for the walls, ceilings, and floors, which are usually installed after the steel formwork is removed.

- Q: How does steel formwork contribute to the overall constructability of the project?

- Steel formwork contributes to the overall constructability of a project by providing a durable and reusable system for creating concrete structures. It allows for efficient and accurate construction, as it can be easily assembled and disassembled, reducing labor and construction time. Its strength and stability ensure that the formwork can withstand the pressure and weight of the concrete, resulting in a high-quality and structurally sound end product. Additionally, steel formwork offers flexibility in design and can be easily adjusted to accommodate changes during the construction process, enhancing the overall constructability of the project.

- Q: Can steel formwork be used for projects with limited formwork storage space?

- Yes, steel formwork can be used for projects with limited formwork storage space. Steel formwork is known for its durability and reusability. It can be easily dismantled and stored in a compact manner, making it a suitable choice for projects with limited storage space. Additionally, steel formwork provides a high level of precision and can be customized to meet specific project requirements, making it a versatile option for various construction projects.

- Q: How does steel formwork affect the overall maintenance requirements of the structure?

- Steel formwork can significantly impact the maintenance requirements of a structure in a positive way. Its durability and strength make it resistant to wear and tear, reducing the need for frequent repairs or replacements. Additionally, steel formwork provides a smooth and even finish, minimizing the potential for cracks or other structural issues that could arise over time. This results in reduced maintenance costs and efforts, ensuring a longer lifespan for the structure.

Send your message to us

Steel Frame Corner-Link for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords