STAINLESS STEEL PIPE CHEAP and GOOD QUALITY from CHINA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,the breif description of the cheap and good quality stainless steel pipe

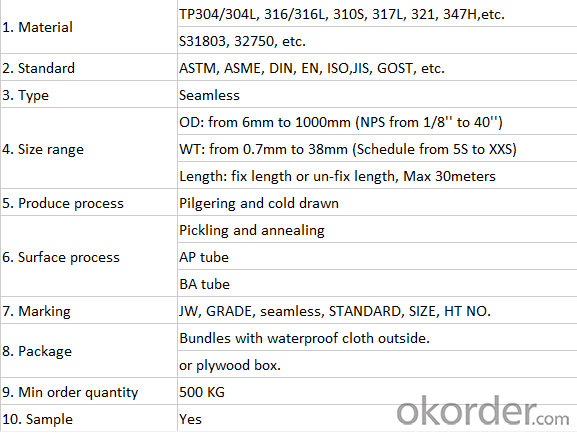

2,our advantage and specifications

1. Our company has been dedicated to producing stainless steel seamless pipe since 2003, owning complete producing technology and abundant managing experience.

2. The raw material such as mother tube, round bar we use is from Chinese biggest and well-known steel mill: Walsin Steel and Yongxing Steel.

3. We have advanced NDT equipments for the tests such as Eddy Current test, Ultrasonic test, Hydraulic test and so on.

4. We have ISO 9001 and PED certificate, and the Third Party Inspection Certificates such as TUV, BV, Lloyd’s, SGS, etc, also can be provided according to customers’ requirements,

5. Wooden case package which is strong and suitable for sea transportation is our main method to pack the pipes. And the economical packing method such as packed in bundles is also welcomed by some customers.

6. The tolerance control we use is D4/T4 (+/-0.1mm) on both inside and outside Diameter and Wall Thickness, which is much higher than international standard ASTM, DIN.

7. The surface condition is one of our main advantages: in order to meet different requirements for surface condition, we have annealing and pickling surface, bright annealing surface, OD polished surface, OD & ID polished surface etc.

8. In order to keep the inside surface of pipe clean and make it free from deburring, our company develops the unique and special technology --- Sponge Washing with high pressure.

9. We have complete after-sale service to deal with the problems in time.

3,Stainless steel maintenance:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

4,FAQ

1. Q: What are your advantageous Products?

A: We specialized in 400 series cold rolled stainless steel coils and plates. Our main products are 430, 410S and 409L.

We also supply stainless steel strips and strips in coil as requested.

2. Q: Can you make DDQ ( Deep Drawing Quality)?

A: Yes, we can. Our material can be used for stainless steel pots, stainless steel sinks, stainless steel bowls etc. U can tell us your usage, and we will adjust the mechanical propertise to meet your requirement.

- Q: What brand of stainless steel pipe cutting machine is good?

- Stainless steel cutting pipe should take into account the cutting speed, accuracy, cross section flatness, surface scratches, cutting tool loss and so on

- Q: What is the difference between 304H and 304 stainless steel pipes?

- The main difference between 304H and 304 stainless steel pipes lies in their carbon content. While both grades are variants of the 304 stainless steel alloy, 304H contains a higher carbon content compared to 304. This higher carbon content allows 304H to be used in higher temperature applications, as it provides improved high-temperature strength and resistance to sensitization. In contrast, 304 stainless steel pipes are more suitable for general-purpose applications, as they offer good corrosion resistance and are commonly used in a wide range of industries. Therefore, the choice between 304H and 304 stainless steel pipes depends on the specific requirements of the application, particularly the operating temperature and the need for enhanced strength and resistance to sensitization.

- Q: What are the different types of stainless steel pipe gaskets?

- Various types of stainless steel pipe gaskets are available to meet specific requirements and needs. Some commonly used types are: 1. Ring Type Joint (RTJ) Gaskets: These gaskets are ideal for high-pressure applications and can withstand extreme temperatures and pressures. They consist of a metallic ring with a soft sealing layer, ensuring a secure and reliable seal. 2. Spiral Wound Gaskets: These gaskets are created by winding a metal strip and filler material in a spiral shape. The metal strip provides strength and stability, while the filler material guarantees a proper seal. They are suitable for various applications, including environments with high temperature and pressure. 3. Metal Jacketed Gaskets: These gaskets have a soft filler material enclosed in a metal jacket, providing additional strength and protection. They are commonly used in high-pressure applications, especially in flange connections. 4. Camprofile Gaskets: These gaskets have a metal core with concentric grooves on both sides. The grooves are filled with a soft sealing material, ensuring effective sealing. They are commonly used in applications requiring resistance to high temperatures and pressures. 5. Double Jacketed Gaskets: These gaskets consist of two metal jackets with a soft filler material in between. This design enhances the sealing performance and is preferred for applications involving high temperatures, pressures, and corrosive environments. 6. Elastomeric Gaskets: These gaskets are made from elastomeric materials like rubber or silicone. They are commonly used in low-pressure applications and offer excellent sealing properties. They are cost-effective and easy to install. To ensure the correct gasket is chosen for a specific application, it is crucial to consider factors such as temperature, pressure, and the nature of the fluid being transported. Seeking guidance from a knowledgeable supplier or engineer can help in making the appropriate selection.

- Q: Are stainless steel pipes suitable for fire sprinkler systems?

- Yes, stainless steel pipes are suitable for fire sprinkler systems. Stainless steel is highly resistant to corrosion, making it a durable and long-lasting material for pipe systems. This resistance to corrosion ensures that the pipes will not weaken or deteriorate over time, ensuring the reliability and effectiveness of the fire sprinkler system. Additionally, stainless steel pipes have excellent heat resistance, which is crucial in fire protection systems. They can withstand high temperatures without warping or melting, ensuring that the pipes will not fail during a fire emergency. Overall, stainless steel pipes provide the necessary strength, durability, and heat resistance required for fire sprinkler systems, making them a suitable choice for such applications.

- Q: What is the difference between 316 and 316L stainless steel pipes?

- The main difference between 316 and 316L stainless steel pipes lies in their carbon content. Both alloys contain the same amount of chromium, nickel, and molybdenum, which contribute to their corrosion resistance properties. However, 316L stainless steel pipes have a lower carbon content compared to 316 stainless steel pipes. The reduced carbon content in 316L stainless steel pipes helps to minimize the formation of carbide precipitation during welding or high-temperature applications. This process, known as sensitization, can lead to intergranular corrosion, compromising the overall corrosion resistance of the material. By reducing the carbon content, 316L stainless steel pipes are less susceptible to sensitization, making them more suitable for applications where welding is involved. Additionally, the lower carbon content of 316L stainless steel pipes results in improved resistance to corrosion in environments with high chloride exposure, such as coastal areas or industrial settings. This makes 316L stainless steel pipes a preferred choice for various industries, including marine, chemical, and pharmaceutical, where resistance to corrosion is crucial. In summary, while both 316 and 316L stainless steel pipes offer excellent corrosion resistance properties, the lower carbon content of 316L stainless steel pipes provides improved weldability and resistance to sensitization. Therefore, 316L stainless steel pipes are often chosen for applications where welding or exposure to corrosive environments is a concern.

- Q: What is the difference between 321 and 316 stainless steel pipes?

- The main difference between 321 and 316 stainless steel pipes lies in their composition and applications. 321 stainless steel contains titanium, which helps improve its resistance to intergranular corrosion and high temperatures, making it suitable for applications in the aerospace and automotive industries. On the other hand, 316 stainless steel is more corrosion-resistant overall and is commonly used in marine environments or for applications involving exposure to chemicals or saltwater.

- Q: What is the difference between 304LN and 316LN stainless steel pipes?

- The composition and inclusion of certain elements distinguish 304LN and 316LN stainless steel pipes from each other. 304LN stainless steel is an austenitic type that contains a low amount of carbon and nitrogen. Its purpose is to provide better strength and corrosion resistance compared to standard 304 stainless steel. The addition of nitrogen encourages the formation of a stable austenite phase, which improves the mechanical properties of the material. On the contrary, 316LN stainless steel is also an austenitic variety but has molybdenum and a higher nickel content compared to 304LN. The inclusion of molybdenum increases the material's resistance to pitting corrosion caused by chlorides and other aggressive environments. The higher nickel content further enhances the corrosion resistance, making it suitable for more demanding applications, such as marine environments or chemical processing. In conclusion, both 304LN and 316LN stainless steel pipes are austenitic and offer good corrosion resistance. However, the addition of molybdenum and higher nickel content in 316LN makes it more suitable for applications requiring enhanced corrosion resistance, especially in aggressive environments.

- Q: Are stainless steel pipes suitable for wastewater treatment ponds?

- Stainless steel pipes are indeed appropriate for wastewater treatment ponds. Due to their exceptional resistance to corrosion, stainless steel proves to be an ideal material for managing wastewater, which can be incredibly corrosive. The robustness and sturdiness of stainless steel pipes enable them to endure the severe conditions and chemicals present in wastewater treatment ponds. Furthermore, stainless steel pipes are effortless to clean and upkeep, guaranteeing the efficacy and efficiency of wastewater treatment procedures. All things considered, stainless steel pipes emerge as a dependable and enduring alternative for wastewater treatment ponds.

- Q: How do stainless steel pipes compare to carbon fiber pipes?

- Stainless steel pipes possess distinct qualities and find usage in diverse fields. Renowned for their robustness and power, they exhibit exceptional resistance to corrosion and can withstand elevated temperatures and pressures. Consequently, they prove suitable for various industries, including oil and gas, chemical, and construction. Boasting an elongated lifespan and the ability to bear heavy loads, stainless steel pipes emerge as a reliable option for numerous applications. Nevertheless, their relatively hefty weight necessitates additional support structures. Conversely, carbon fiber pipes, characterized by their lightness and high strength-to-weight ratio, serve as an alternative. Crafted from carbon fibers embedded in a resin matrix, they yield a formidable and rigid material. Aerospace, automotive, and sports equipment industries commonly employ carbon fiber pipes. Their lightweight nature permits enhanced fuel efficiency in vehicles and augmented performance in sports equipment. However, carbon fiber pipes prove pricier than their stainless steel counterparts and may lack the desired resilience to extreme temperatures or corrosive surroundings. To summarize, stainless steel pipes excel in durability and corrosion resistance, making them well-suited for demanding tasks. Carbon fiber pipes, on the other hand, offer lightweight construction and a commendable strength-to-weight ratio, rendering them ideal for weight reduction-focused applications. Ultimately, the choice between stainless steel and carbon fiber pipes hinges on specific requirements and the trade-offs between cost, weight, and performance.

- Q: What are the dimensions and sizes of stainless steel pipes?

- Different industrial and commercial applications are served by stainless steel pipes of varying dimensions and sizes. The sizing of these pipes is determined by their nominal diameter (DN) and the schedule or wall thickness. The nominal diameter represents the approximate internal diameter of the pipe and is commonly expressed in inches or millimeters. The most frequently available stainless steel pipe sizes range from 1/8 inch (3.175 mm) to 48 inches (1219 mm) in nominal diameter. However, larger sizes can be custom-made to meet specific requirements. The schedule or wall thickness of stainless steel pipes is indicated by a schedule number, which reflects the thickness of the pipe's walls. The most commonly used schedules for stainless steel pipes include Sch 5, Sch 10, Sch 40, and Sch 80. The higher the schedule number, the thicker the walls of the pipe. Apart from the dimensions and sizes, stainless steel pipes also come in various lengths, typically ranging from 20 feet (6.1 meters) to 40 feet (12.2 meters). Custom lengths can also be ordered based on specific project needs. It is important to note that these dimensions and sizes may differ based on the standards and specifications established by different countries and industries. Hence, it is crucial to consult the relevant standards or collaborate with a reliable supplier to ensure the precise dimensions and sizes of stainless steel pipes for a particular application.

Send your message to us

STAINLESS STEEL PIPE CHEAP and GOOD QUALITY from CHINA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords