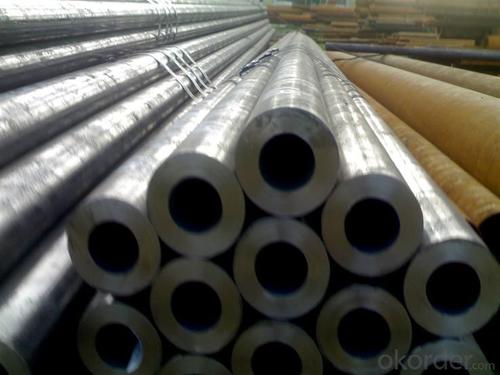

SA335/SA335M Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ASTM A335 Seamless Alloy-Steel Pipe

Standard: BS 1139, BS 3059-2, JIS G3454-2007

Grade: 10#-45#, 15NiCuMoNb5, 10Cr9Mo1VNb

Detailed introduction to ASTM A335 seamless alloy steel pipe:

ASTM A335 seamless alloy steel pipe

FAQ:

1) why you chose us ?

Professional Manufacturer and supplier of Steel pipe

More than 14 years’ professional producing experience

We can get the lowest ex-factory prices. The price are quite reasonable and it is lower than our commercial peers. also, we can guarantee the qualities of our products.

BV, ISO certificates and SGS test can be provided to assure the quality of our products.

2) Our minimum order quantity:

10 Metric Tons or one 20ft or 40ft Container.

3) How about the Delivery Time?

The steel pipe will be produced since we getting your deposit by T/T or Your original L/C. For normal size, some stocks in our factory now, we can supply once you need.

4)What kind of payment does your company support?

T/T, 100% L/C at sight, Cash, Western Union are all accepted.

5) Do you charge for the samples?

According to our company principle, we just charge for samples, you pay for the freight /courier charge.

6) Main market:

Mid East, South America, Africa, Southeast Asia, India etc

FAQ:

1) why you chose us ?

Professional Manufacturer and supplier of Steel pipe

More than 14 years’ professional producing experience

We can get the lowest ex-factory prices. The price are quite reasonable and it is lower than our commercial peers. also, we can guarantee the qualities of our products.

BV, ISO certificates and SGS test can be provided to assure the quality of our products.

2) Our minimum order quantity:

10 Metric Tons or one 20ft or 40ft Container.

3) How about the Delivery Time?

The steel pipe will be produced since we getting your deposit by T/T or Your original L/C. For normal size, some stocks in our factory now, we can supply once you need.

4)What kind of payment does your company support?

T/T, 100% L/C at sight, Cash, Western Union are all accepted.

5) Do you charge for the samples?

According to our company principle, we just charge for samples, you pay for the freight /courier charge.

6) Main market:

Mid East, South America, Africa, Southeast Asia, India etc

- Q: Can stainless steel pipes be polished?

- Yes, stainless steel pipes can be polished. Stainless steel is a versatile and durable material that can be polished to enhance its appearance and provide a smoother finish. Polishing stainless steel pipes involves using abrasive materials, such as sandpaper or polishing compounds, to remove any imperfections, scratches, or oxidation from the surface. This process not only improves the aesthetic appeal of the pipes but also helps to maintain their corrosion resistance and prolong their lifespan. Polished stainless steel pipes are commonly used in various industries, including architecture, interior design, automotive, and food processing, where a clean and polished look is desired.

- Q: Can stainless steel pipes be used for chemical pumps?

- Indeed, chemical pumps can utilize stainless steel pipes. Renowned for its corrosion resistance, stainless steel proves to be an appropriate substance for managing diverse chemicals. Its ability to endure the corrosive properties of numerous chemicals safeguards against contamination of the fluids being pumped. Furthermore, stainless steel pipes provide commendable mechanical strength and endurance, rendering them suitable for chemical pumps that necessitate reliability and sustained effectiveness. Nonetheless, it is crucial to take into account the precise demands of the chemicals being pumped and seek guidance from specialists or manufacturers to guarantee the compatibility of the chosen stainless steel with the specific chemicals and operational circumstances.

- Q: Are stainless steel pipes suitable for liquid storage tanks?

- Yes, stainless steel pipes are suitable for liquid storage tanks. Stainless steel offers excellent corrosion resistance, durability, and strength, making it a reliable choice for storing various liquids. Additionally, stainless steel is hygienic, easy to clean, and has a long lifespan, making it a preferred material for liquid storage tanks in industries such as food processing, pharmaceuticals, and chemicals.

- Q: Can stainless steel pipes be used in the automotive industry?

- Yes, stainless steel pipes can be used in the automotive industry. They are commonly used for various applications such as exhaust systems, fuel lines, and cooling systems due to their high corrosion resistance, durability, and ability to withstand high temperatures. This makes stainless steel pipes a preferred choice for automotive manufacturers as they provide reliability and longevity to the vehicles.

- Q: Can stainless steel pipes be used for drinking water systems?

- Indeed, drinking water systems can utilize stainless steel pipes. Stainless steel, being an exceedingly durable and corrosion-resistant substance, is well-suited for deployment within plumbing systems. Furthermore, its non-reactive nature prevents the release of harmful chemicals into the water. Moreover, stainless steel pipes are effortlessly cleaned and maintained, thus minimizing the likelihood of bacterial proliferation and guaranteeing the safety and excellence of the drinking water.

- Q: What is the difference between 304J3 and 316J3 stainless steel pipes?

- The composition and corrosion resistance properties distinguish 304J3 stainless steel pipes from 316J3 stainless steel pipes. 304J3 stainless steel is characterized by its 18% chromium and 8% nickel content. This grade is known for its excellent corrosion resistance, high strength, and good formability. It finds applications in various fields, including food processing, chemical processing, and architecture. In contrast, 316J3 stainless steel comprises 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The additional molybdenum enhances its corrosion resistance, particularly against chloride environments. Consequently, 316J3 stainless steel is commonly used in more demanding situations such as marine environments, pharmaceutical equipment, and coastal structures. To summarize, the main distinction between 304J3 and 316J3 stainless steel pipes lies in their composition and resulting corrosion resistance. While both grades provide good corrosion resistance, 316J3 stainless steel offers superior resistance in chloride-rich environments, making it suitable for more challenging applications.

- Q: What are the different types of stainless steel pipe insulation?

- There are several different types of stainless steel pipe insulation available on the market. These types can vary in terms of their material composition, construction, and insulation properties. One common type is fiberglass insulation, which consists of a layer of fiberglass material wrapped around the stainless steel pipe. This type of insulation is known for its excellent thermal insulation properties and its ability to withstand high temperatures. It is also resistant to moisture, making it suitable for both indoor and outdoor applications. Another type is foam insulation, which is made from a foamed plastic material such as polyurethane or polystyrene. Foam insulation is lightweight and easy to install, and it provides good thermal insulation as well as acoustic insulation. It is commonly used in residential and commercial buildings to insulate hot water pipes and HVAC systems. Additionally, there are elastomeric insulation materials, which are flexible rubber-like materials that can be easily wrapped around the stainless steel pipe. These materials are known for their excellent thermal insulation properties and their ability to resist moisture and condensation. Elastomeric insulation is commonly used in refrigeration and air conditioning systems. Finally, there are also pre-insulated stainless steel pipe systems, which consist of a stainless steel pipe already insulated with a layer of insulation material. This type of insulation is commonly used in industrial applications where thermal insulation is critical, such as in chemical plants or oil refineries. In conclusion, the different types of stainless steel pipe insulation include fiberglass insulation, foam insulation, elastomeric insulation, and pre-insulated pipe systems. The choice of insulation type depends on factors such as the application, desired insulation properties, and budget.

- Q: Are stainless steel pipes suitable for brewing systems?

- Yes, stainless steel pipes are highly suitable for brewing systems. Stainless steel is the preferred material for brewing equipment due to its excellent corrosion resistance, hygienic properties, and durability. Stainless steel pipes do not react with the acidic components present in brewing, ensuring that there are no unwanted flavors or contaminants introduced into the beer. Additionally, stainless steel pipes are easy to clean and maintain, making them ideal for the brewing process. Overall, stainless steel pipes provide a reliable and long-lasting solution for brewing systems, ensuring the production of high-quality and uncontaminated beer.

- Q: Are stainless steel pipes suitable for chemical refineries?

- Chemical refineries can rely on stainless steel pipes for their operations. The exceptional corrosion resistance properties of stainless steel make it the perfect choice for handling corrosive substances in these refineries. These pipes demonstrate remarkable chemical resistance, even in harsh and high-temperature environments, which is crucial during the refining process. Furthermore, stainless steel pipes possess great durability and can withstand the high-pressure conditions commonly encountered in refineries. They also exhibit high tensile strength, ensuring the safety and integrity of the entire piping system. In addition, stainless steel pipes are easy to clean and maintain, which is vital for preserving the purity and quality of the refined chemicals. All in all, stainless steel pipes provide a reliable and efficient solution for transporting chemicals in chemical refineries.

- Q: What is the difference between 2205 and 316 stainless steel pipes?

- The chemical composition and resulting properties of 2205 and 316 stainless steel pipes differ significantly. Firstly, 2205 is a duplex stainless steel that combines austenitic and ferritic stainless steels. This unique composition grants it exceptional corrosion resistance, high strength, and weldability. It is specifically engineered to endure highly corrosive surroundings, thus making it suitable for applications in the oil and gas industry, chemical processing, and marine environments. In contrast, 316 stainless steel is an austenitic stainless steel with a higher proportion of chromium and nickel compared to 2205. Consequently, it possesses superior corrosion resistance, particularly against chlorides and other aggressive chemicals. It also exhibits commendable heat resistance and is widely employed in industries such as food processing, pharmaceuticals, and medical equipment. Regarding mechanical properties, 2205 stainless steel generally boasts greater tensile and yield strength than 316 stainless steel. This renders it more appropriate for applications where strength and durability are critical factors. However, 316 stainless steel offers better formability and is easier to work with during fabrication. In conclusion, while both 2205 and 316 stainless steel pipes provide corrosion resistance, the choice between them depends on the specific requirements of the application. 2205 is preferred for highly corrosive environments and applications necessitating high strength, whereas 316 is commonly utilized in industries where superior corrosion resistance and good formability are pivotal.

Send your message to us

SA335/SA335M Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords