Carbon Steel Steamless Pipe With Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless Pipe ASTM A106/53:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

Commodity Name: Seamless steel pipe

Standard: API,GB,ASTM,ASME,DIN

Quality grade: 10#, 20#, A106B, A53B, API 5L B, Q235, Q345, ST37-2, ST 45, ST52.etc.

Dimension: OD: 1/2"-24" WT: 2.5-80mm, SCH10~SCH40~XXL length: 5.8m,6m,8m,9m,12m

application

carbon seamless steel pipes are widely used in gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

8.packing and shipment

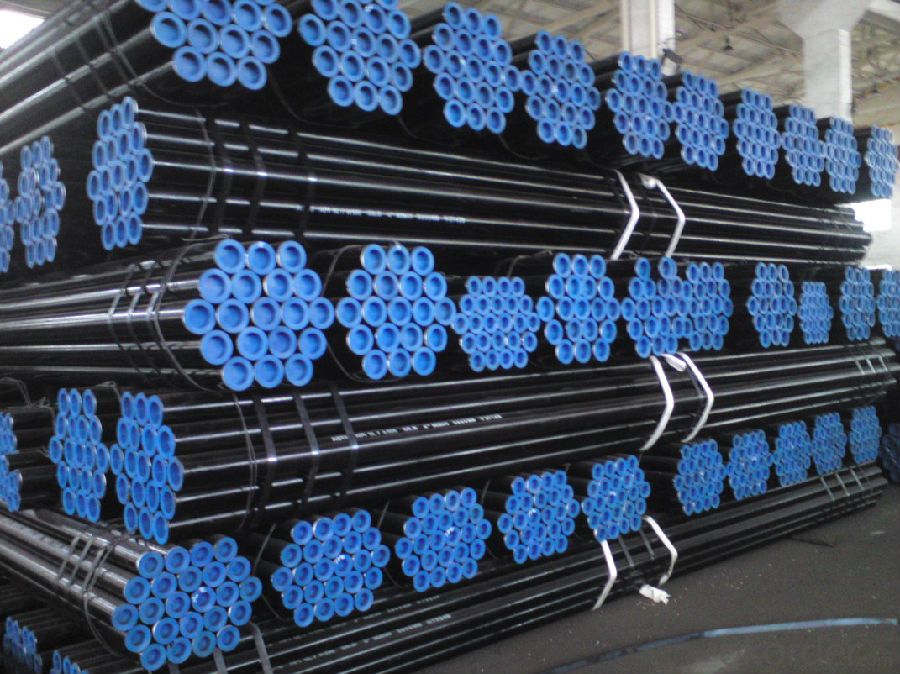

Packaged in bundles,as per customers' requirements, it can also bepackagesd as beveled ends, typed marking, black painting, plastic caps protection,woven bags packing

For 20" container the max length is 5.8m; For 40" container the max length is 12m. other options are available based on customer requests. Please discuss when placing orders.

2、Main Features of the Seamless Pipe ASTM A106/53:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、Seamless Pipe ASTM A106/53 Images:

- Q: What is the average lifespan of steel pipes in different applications?

- The lifespan of steel pipes in different applications can vary due to various factors, such as the quality of the steel, the environment in which they are used, and the maintenance and care they receive. Water supply lines typically have steel pipes that can last around 50 to 70 years on average. These pipes are often made of high-quality steel and experience less corrosive environments. However, the presence of corrosive substances, water chemistry, and soil conditions can significantly impact their lifespan. For industrial applications like oil and gas pipelines, steel pipes generally have a lifespan ranging from 20 to 50 years. These pipes are exposed to aggressive environments with high temperatures, pressure, and corrosive substances. Extending their lifespan can be achieved through regular inspections, maintenance, and corrosion protection measures. In construction applications, steel pipes used for structural purposes can last an average of 50 to 100 years or longer. These pipes are designed to withstand heavy loads and are often safeguarded by coatings or insulation to prevent corrosion. It's important to understand that these are average lifespans, and individual pipes may have shorter or longer lifespans depending on specific conditions. Ensuring the longevity of steel pipes in different applications can be achieved through regular inspections, maintenance, and timely repairs or replacements when necessary.

- Q: How are steel pipes affected by international trade policies?

- Steel pipes can be significantly impacted by international trade policies. Trade policies, such as tariffs or quotas, can increase the cost of importing steel pipes, making them more expensive for domestic consumers. On the other hand, trade policies that promote free trade can lead to increased competition and potentially lower prices for steel pipes. Additionally, trade policies may also affect the availability of certain types of steel pipes, depending on the regulations and restrictions imposed by different countries. Overall, international trade policies play a crucial role in shaping the market dynamics and influencing the supply, demand, and pricing of steel pipes.

- Q: What are the thermal properties of steel pipes?

- Steel pipes have excellent thermal conductivity, meaning they can efficiently transfer heat. They also have a high melting point and can withstand high temperatures without deformation. Additionally, steel pipes have low thermal expansion, allowing them to maintain their shape and structural integrity even when exposed to extreme temperature changes.

- Q: What are the different types of pipe connections used with steel pipes?

- Steel pipes are commonly connected using various types of pipe connections. The most frequently used connections are as follows: 1. Threaded connections: These connections involve screwing the ends of the pipe and using fittings with threads to connect them. They are typically used for smaller pipes and are easy to install and remove. 2. Welded connections: Welding is a popular method for joining steel pipes. This involves melting the metal and fusing the ends of the pipes together. Welded connections are strong and durable, making them suitable for high-pressure applications. 3. Flanged connections: Flanges are used to connect pipes by bolting them together. These connections are commonly used in industrial settings and are preferred for larger pipes or when easy disassembly is required for maintenance. 4. Grooved connections: Grooved fittings with internal grooves are used to connect pipes. These connections are commonly found in fire protection systems and are quick and straightforward to install. 5. Compression connections: Compression fittings are used to connect steel pipes by compressing a ferrule onto the pipe. This type of connection is frequently used in plumbing and provides a secure and tight seal. 6. Mechanical connections: Mechanical connections, such as couplings or clamps, allow for pipe connection without welding or threading. These connections are often used for temporary or emergency repairs. Each type of pipe connection has its own advantages and disadvantages. The choice of connection method depends on factors such as the application, pipe size, and installation requirements. It is crucial to carefully consider these factors to ensure a reliable and secure connection for steel pipes.

- Q: What are the different types of connections used with steel pipes?

- There are several types of connections commonly used with steel pipes, including threaded connections, welded connections, flanged connections, and grooved connections.

- Q: Are steel pipes suitable for high-temperature applications?

- Yes, steel pipes are suitable for high-temperature applications. Steel has excellent heat resistance properties and can withstand high temperatures without deformation or structural failure. Additionally, steel pipes can be specifically designed and coated to enhance their heat resistance, making them ideal for various industrial processes and applications involving high temperatures.

- Q: What place must use galvanized steel pipe to make lighting line?

- Galvanized steel pipe with hot-dip galvanizing or galvanized coating on it. Galvanizing can increase the corrosion resistance and prolong the service life of the steel pipe. The use of galvanized pipe is very wide, except for water, gas, oil and other general low pressure fluid pipeline, is used in petroleum industry especially offshore oil well pipe and oil pipe, chemical coking equipment oil heater, cooler, oil pipe exchanger for coal distillation, and support piles, Zhanqiao mine tunnel the tubes.

- Q: What are the environmental impacts of steel pipe production and disposal?

- The production and disposal of steel pipes have significant environmental impacts. Firstly, the production of steel pipes requires the extraction of raw materials such as iron ore, coal, and limestone. This extraction process leads to habitat destruction, deforestation, and soil erosion. Additionally, mining and processing these materials require a considerable amount of energy, often derived from fossil fuels, contributing to greenhouse gas emissions and air pollution. The manufacturing process itself involves various stages, including melting, casting, rolling, and coating, all of which require substantial energy inputs and emit significant amounts of carbon dioxide and other greenhouse gases. Moreover, the production of steel pipes involves the use of chemicals and additives that can be harmful to the environment if not managed properly. Furthermore, during the disposal of steel pipes, if not recycled or properly managed, they can end up in landfills, contributing to waste accumulation and taking up valuable space. Steel is generally non-biodegradable and can take hundreds of years to decompose. When steel pipes are dumped in landfills, they can release toxic substances and heavy metals, which can contaminate soil and groundwater. However, it is important to note that steel pipes are highly recyclable, and recycling them significantly reduces the environmental impact. Recycling steel pipes helps conserve natural resources, reduces energy consumption, and lowers greenhouse gas emissions. Additionally, using recycled steel in the production of new pipes requires less energy and results in fewer emissions compared to using virgin materials. To minimize the environmental impacts of steel pipe production and disposal, it is crucial to promote sustainable practices throughout the entire lifecycle of the product. This includes reducing energy consumption, utilizing renewable energy sources, implementing proper waste management strategies, and encouraging the recycling and reuse of steel pipes.

- Q: Are steel pipes environmentally friendly?

- Steel pipes can be considered environmentally friendly for several reasons. Firstly, steel is a highly durable and long-lasting material, which means that steel pipes have a longer lifespan compared to other materials like plastic pipes. This reduces the need for frequent replacements and repairs, reducing waste and conserving resources. Secondly, steel is a highly recyclable material. At the end of their lifespan, steel pipes can be easily and efficiently recycled, without losing their properties or quality. This reduces the demand for new steel production, which often requires significant amounts of energy and resources. Furthermore, steel pipes have a high resistance to corrosion, which means that they require fewer chemical treatments to prevent rusting and maintain their structural integrity. This reduces the release of harmful chemicals into the environment and minimizes the impact on ecosystems and human health. It is also worth mentioning that steel pipes are used in various industries, including water supply and wastewater management. Steel pipes are known for their excellent strength and reliability, ensuring the safe and efficient transportation of fluids. This reduces the risk of leaks and spills, preventing contamination of water sources and protecting the environment. However, it is important to note that the production of steel pipes does have some environmental impact. The extraction of raw materials, such as iron ore and coal, requires energy and can contribute to deforestation, habitat destruction, and greenhouse gas emissions. Additionally, the manufacturing process itself generates emissions and waste. Overall, while steel pipes may not be completely free from environmental impact, their durability, recyclability, and resistance to corrosion make them a relatively environmentally friendly choice compared to other materials.

- Q: How are steel pipes used in the construction of sewer systems?

- Steel pipes are commonly used in the construction of sewer systems due to their durability and strength. These pipes are used to transport sewage and wastewater from households and businesses to treatment plants or disposal sites. They are resistant to corrosion and can withstand high pressure, making them ideal for underground installations. Additionally, steel pipes can be manufactured in various sizes and lengths, allowing for efficient and cost-effective installation in sewer infrastructure.

Send your message to us

Carbon Steel Steamless Pipe With Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords