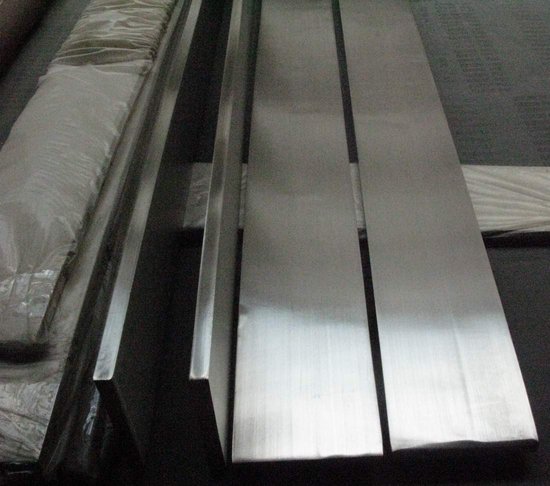

Stainless Steel Flat Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade:

1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. Cherryliu@okorder.com |

- Q: Are stainless steel pipes suitable for oil and gas refineries?

- Yes, stainless steel pipes are suitable for oil and gas refineries. Stainless steel pipes offer excellent corrosion resistance and can withstand high temperatures and pressures, making them ideal for transporting and processing oil and gas in refineries. Additionally, stainless steel pipes are durable and have a long lifespan, which reduces the need for frequent replacements and maintenance.

- Q: Are stainless steel pipes suitable for underground applications?

- Indeed, underground applications are well-suited for the utilization of stainless steel pipes. Renowned for its remarkable resistance to corrosion, stainless steel proves to be an exceptional selection for installations that are situated beneath the surface, where pipes are regularly exposed to moisture, soil, and other detrimental elements. Its ability to endure harsh environments while maintaining its structural integrity over time is truly impressive. Moreover, stainless steel pipes possess superior strength and durability, enabling them to withstand the immense pressure and stress associated with being buried underground. Furthermore, the non-reactive nature of stainless steel ensures that the water or fluid flowing through these pipes remains uncontaminated. Overall, stainless steel pipes can be relied upon as a dependable and long-lasting solution for underground applications.

- Q: What is the maximum pressure that stainless steel pipes can handle?

- The maximum pressure stainless steel pipes can handle relies on various factors including the grade of stainless steel, the dimensions of the pipe, the temperature of the fluid being transported, and the specific use of the pipe. Stainless steel pipes possess high strength and resistance to corrosion, making them suitable for applications where pressure is a concern. The commonly used stainless steel grades for pipes are 304 and 316, each having distinct mechanical properties and maximum pressure ratings. For example, type 304 stainless steel pipes typically have a maximum pressure rating of approximately 14,000 psi at room temperature. However, this rating can vary based on the pipe's wall thickness and diameter. Generally, thicker pipes with larger diameters can withstand higher pressures. Contrarily, type 316 stainless steel pipes are renowned for their enhanced corrosion resistance, particularly in environments with chloride ions. They usually have a slightly higher maximum pressure rating compared to type 304, typically around 15,000 psi at room temperature. It is crucial to note that as the fluid temperature rises, the maximum pressure rating decreases. Stainless steel's mechanical properties alter with temperature, resulting in reduced strength as the temperature increases. Hence, it is vital to consider the maximum operating temperature and determine the appropriate pressure rating accordingly. Furthermore, it is always advisable to consult relevant industry standards, codes, and regulations, such as ASME B31.3 for process piping or ASME B31.1 for power piping, as they offer comprehensive guidelines on the maximum pressure ratings for stainless steel pipes in various applications. To ensure the safety and reliability of stainless steel pipes under high-pressure circumstances, it is recommended to seek advice from a qualified engineer or a specialist in stainless steel piping systems. They can assess the specific requirements of your application and provide accurate information regarding the maximum pressure capacity of stainless steel pipes.

- Q: Are stainless steel pipes suitable for architectural applications?

- Indeed, architectural applications are well-suited for stainless steel pipes. This material, known for its durability and resistance to corrosion, can endure even the harshest environmental conditions, making it an ideal option for architectural projects. Notably, it is frequently utilized in structural applications, such as handrails, guardrails, and balustrades, owing to its robustness and attractive appearance. Moreover, stainless steel pipes are highly versatile, allowing for easy shaping and welding to create distinctive designs and structures. Furthermore, they require minimal maintenance and can be polished to a brilliant shine, thereby enhancing the overall aesthetic of architectural projects. In summary, stainless steel pipes are an exceptional choice for architectural applications due to their durability, resistance to corrosion, versatility, and aesthetic appeal.

- Q: Are stainless steel pipes resistant to caustic solutions?

- Yes, stainless steel pipes are generally resistant to caustic solutions. Stainless steel is known for its excellent corrosion resistance, which makes it a preferred material for various applications in industries that deal with corrosive substances, including caustic solutions. The high chromium content in stainless steel forms a protective layer on the surface of the pipe, preventing it from reacting with caustic solutions and other corrosive materials. However, it is important to note that the resistance of stainless steel pipes can vary depending on the specific grade and composition of the stainless steel being used. Therefore, it is advisable to consult with a professional or refer to the specific stainless steel grade's corrosion resistance properties to ensure its suitability for the intended application with caustic solutions.

- Q: What is the difference between 2205 and 316L stainless steel pipes?

- The main difference between 2205 and 316L stainless steel pipes lies in their chemical composition and their intended applications. 2205 stainless steel is a duplex stainless steel, meaning it is composed of two phases - austenite and ferrite. This composition gives it excellent corrosion resistance, especially in environments with high chloride content. 2205 stainless steel pipes are commonly used in industries such as oil and gas, chemical processing, and marine applications, where resistance to corrosion and high strength are crucial. On the other hand, 316L stainless steel is an austenitic stainless steel with a lower carbon content compared to other grades in the 300 series. It offers good corrosion resistance, especially to acids and chloride solutions, making it suitable for various applications, including food processing, pharmaceuticals, and medical equipment manufacturing. In terms of mechanical properties, 2205 stainless steel pipes generally have higher tensile strength and yield strength compared to 316L stainless steel pipes. This makes 2205 pipes more suitable for applications requiring greater strength and load-bearing capabilities. It is important to note that both grades of stainless steel pipes have their own advantages and limitations. The choice between 2205 and 316L stainless steel pipes depends on the specific application, environmental conditions, and budgetary considerations. Consulting with a materials engineer or a stainless steel expert can help determine the most suitable grade for a particular project.

- Q: Can stainless steel pipes be fabricated?

- Yes, stainless steel pipes can be fabricated. Stainless steel is a versatile material that can be easily manipulated and fabricated into various shapes and sizes. Fabrication processes such as cutting, bending, welding, and threading can be used to shape stainless steel pipes according to specific requirements. These pipes can be fabricated for use in various industries, including construction, automotive, oil and gas, and plumbing, among others. Stainless steel's corrosion resistance and durability make it an ideal choice for fabricating pipes that need to withstand harsh environmental conditions.

- Q: How do stainless steel pipes compare to polyethylene pipes?

- Stainless steel pipes and polyethylene pipes are two commonly used materials for various plumbing and industrial applications. While both materials have their advantages and disadvantages, they differ in terms of strength, durability, cost, and application suitability. Stainless steel pipes are known for their exceptional strength and durability. They can withstand high pressure and temperature, making them suitable for applications in industries such as oil and gas, chemical processing, and water distribution. Stainless steel pipes are also resistant to corrosion, rust, and fire, making them a reliable choice for long-term use. However, they tend to be heavier and more expensive than polyethylene pipes. On the other hand, polyethylene pipes are lightweight, flexible, and relatively inexpensive compared to stainless steel pipes. They are commonly used in applications such as irrigation, water supply, and drainage systems. Polyethylene pipes are resistant to chemicals, impact, and abrasion, making them suitable for underground installation. However, they may not be as durable as stainless steel pipes and may require more frequent replacements or repairs in some cases. In terms of installation and maintenance, stainless steel pipes are generally more demanding as they require specialized tools and skills. Polyethylene pipes, on the other hand, are easier to install and maintain due to their flexibility and simple jointing techniques. Ultimately, the choice between stainless steel pipes and polyethylene pipes depends on the specific requirements of the application. If strength, durability, and resistance to extreme conditions are crucial, stainless steel pipes are the preferred option. For less demanding applications that require cost-effectiveness, flexibility, and ease of installation, polyethylene pipes may be more suitable. It is important to consider factors such as budget, operating conditions, lifespan, and maintenance requirements when comparing these two pipe materials.

- Q: Can stainless steel pipes be used for sewage disposal?

- Yes, stainless steel pipes can be used for sewage disposal. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for handling sewage and wastewater. It is resistant to various chemicals and acids commonly found in sewage, ensuring the pipes' longevity and minimizing the risk of leaks or breaks. Additionally, stainless steel pipes have smooth inner surfaces, which helps prevent the buildup of waste and inhibits the growth of bacteria or other harmful substances. Overall, stainless steel pipes are a reliable and appropriate choice for sewage disposal systems.

- Q: Can stainless steel pipes be insulated with polyphthalamide?

- No, stainless steel pipes cannot be directly insulated with polyphthalamide. Polyphthalamide (PPA) is a high-performance thermoplastic that is often used as an insulating material due to its excellent thermal and electrical properties. However, PPA is typically used as a polymer or resin for injection molding applications, rather than as an insulation material for pipes. When it comes to insulating stainless steel pipes, there are several commonly used insulation materials such as fiberglass, mineral wool, or foam insulation. These materials are designed to provide thermal insulation and prevent heat transfer, while also offering protection against corrosion and condensation. If there is a need to insulate stainless steel pipes, it is best to choose an appropriate insulation material that is specifically designed for pipe insulation, rather than attempting to use polyphthalamide which is not typically used for this purpose.

Send your message to us

Stainless Steel Flat Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords