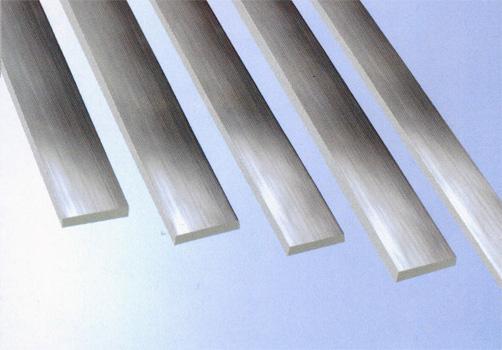

201 HL Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. Cherryliu@okorder.com |

- Q: Can stainless steel pipes be used for oil refinery applications?

- Oil refinery applications can indeed use stainless steel pipes. Due to its exceptional resistance to corrosion, high durability, and strength, stainless steel is widely utilized in the oil and gas industry. Oil refineries face harsh and corrosive environments, including exposure to various chemicals, high temperatures, and pressure. Stainless steel pipes have the ability to withstand these conditions and provide long-lasting performance. Stainless steel pipes possess resistance to corrosion resulting from acidic and alkaline substances, which are commonly present in oil refinery operations. They also exhibit excellent resistance against pitting and crevice corrosion, making them ideal for handling crude oil, petroleum products, and other corrosive media. Moreover, stainless steel pipes can handle high temperatures without compromising their strength and integrity. This quality is crucial in oil refineries where heating and cooling processes are involved. Apart from corrosion resistance and high-temperature capabilities, stainless steel pipes also possess exceptional mechanical properties. They are robust, durable, and possess good weldability, making them suitable for the demanding conditions of oil refinery applications. In conclusion, stainless steel pipes are a reliable option for oil refinery applications due to their corrosion resistance, high-temperature capabilities, and mechanical properties. They ensure the safe and efficient transportation of oil and petroleum products, thereby contributing to the seamless operations of oil refineries.

- Q: What is the maximum temperature for stainless steel pipes?

- The maximum temperature for stainless steel pipes can vary depending on the specific grade of stainless steel being used. However, in general, stainless steel pipes can typically withstand temperatures ranging from 1000 to 1600 degrees Fahrenheit (537 to 871 degrees Celsius).

- Q: Can stainless steel pipes be used for food processing?

- Yes, stainless steel pipes can be used for food processing. Stainless steel is a popular choice in the food industry due to its excellent corrosion resistance, high strength, and hygiene properties. It is non-reactive, which means it does not interact with food and does not impart any taste or odor. Stainless steel pipes are easy to clean, sanitize, and maintain, making them suitable for use in food processing applications where cleanliness and hygiene are crucial. Additionally, stainless steel pipes can withstand high temperatures and pressures, making them ideal for various food processing operations such as transportation, storage, and distribution of food products.

- Q: How do stainless steel pipes compare to PVC-U pipes?

- Stainless steel pipes and PVC-U pipes are two commonly used materials for various piping applications, and they have their own unique characteristics and advantages. Firstly, stainless steel pipes are known for their exceptional durability and strength. They are highly resistant to corrosion, rust, and other chemical reactions, making them ideal for applications where the pipes come into contact with aggressive substances or are exposed to harsh environments. Stainless steel pipes can withstand high temperatures and pressures, making them suitable for demanding industrial applications. On the other hand, PVC-U (polyvinyl chloride unplasticized) pipes are lightweight and easy to install. They are cost-effective and have good chemical resistance, especially against most acids, alkalis, and salts. PVC-U pipes are commonly used in plumbing, irrigation, and drainage systems due to their excellent flow characteristics and low maintenance requirements. In terms of versatility, stainless steel pipes can be used for a wide range of applications, including water supply, gas distribution, oil and gas pipelines, and sewage systems. They are often preferred in industrial settings where reliability and longevity are crucial. PVC-U pipes, on the other hand, are more commonly used in residential and commercial settings where cost-efficiency and ease of installation are important factors. It is worth noting that stainless steel pipes are typically more expensive than PVC-U pipes, both in terms of material cost and installation. However, given their longer lifespan and superior resistance to corrosion and chemical reactions, they often prove to be a more cost-effective option in the long run. Ultimately, the choice between stainless steel pipes and PVC-U pipes depends on the specific requirements of the application. Factors such as cost, durability, resistance to corrosion, ease of installation, and maintenance should all be taken into consideration when comparing these two materials for a particular piping project.

- Q: Are stainless steel pipes resistant to pitting and crevice corrosion?

- Yes, stainless steel pipes are generally resistant to pitting and crevice corrosion due to their high chromium content, which forms a protective oxide layer on the surface, preventing corrosion. However, the resistance can vary depending on the specific grade of stainless steel and the environment in which the pipes are used.

- Q: What is the difference between 440C and 440F stainless steel pipes?

- The main difference between 440C and 440F stainless steel pipes lies in their carbon content. 440C stainless steel has a higher carbon content, making it harder and more resistant to wear and corrosion. On the other hand, 440F stainless steel has a lower carbon content, which enhances its machinability and makes it easier to form into various shapes.

- Q: Can stainless steel pipes be used for sewage disposal?

- Yes, stainless steel pipes can be used for sewage disposal. Stainless steel is highly resistant to corrosion, making it a suitable material for sewage pipes that are exposed to various chemicals and moisture. Additionally, stainless steel pipes have smooth surfaces, which helps prevent the buildup of debris and facilitates the flow of sewage.

- Q: Can stainless steel pipes be used for boiler tubes?

- Yes, stainless steel pipes can be used for boiler tubes. Stainless steel possesses excellent corrosion resistance, high strength, and heat resistance, making it a suitable material for boiler tubes that are subjected to high temperatures and pressure. Additionally, stainless steel's durability and long lifespan make it a popular choice for boiler applications.

- Q: How do stainless steel pipes compare to PEX pipes?

- Stainless steel pipes and PEX pipes have different characteristics and applications, which make them suitable for different plumbing systems. Stainless steel pipes are known for their durability and strength. They are highly resistant to corrosion, which makes them ideal for use in water supply systems, especially in areas with aggressive water conditions. Stainless steel pipes can withstand high pressure and temperature, making them suitable for both residential and commercial applications. They are also fire-resistant, which adds to their safety profile. Additionally, stainless steel pipes have a long lifespan and require minimal maintenance, making them a cost-effective option in the long run. On the other hand, PEX pipes are made of cross-linked polyethylene, which offers flexibility and ease of installation. PEX pipes are highly resistant to freezing and bursting, making them suitable for cold-climate regions. They have the ability to expand and contract, which reduces the risk of leaks or bursts due to temperature changes. PEX pipes are also corrosion-resistant, eliminating the need for expensive and time-consuming maintenance. Additionally, PEX pipes are quieter compared to metal pipes, as they dampen noise and vibration. When choosing between stainless steel pipes and PEX pipes, it is essential to consider factors such as the specific plumbing requirements, budget, and local building codes. While stainless steel pipes excel in durability and strength, PEX pipes offer flexibility and ease of installation. Ultimately, the choice between the two will depend on the specific needs of the plumbing system and the preferences of the homeowner or plumbing professional.

- Q: How do stainless steel pipes differ from other types of pipes?

- Stainless steel pipes differ from other types of pipes primarily due to their corrosion-resistant properties, which make them highly durable and long-lasting. Unlike other pipes, stainless steel pipes are less prone to rusting or corroding, making them suitable for a wide range of applications, particularly in industries where hygiene and cleanliness are essential. Additionally, stainless steel pipes have high strength and heat resistance, making them capable of withstanding extreme temperatures and pressures, making them a preferred choice for various industrial and commercial applications.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

201 HL Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords