CNBM hot sell 304,202 stainless steel pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

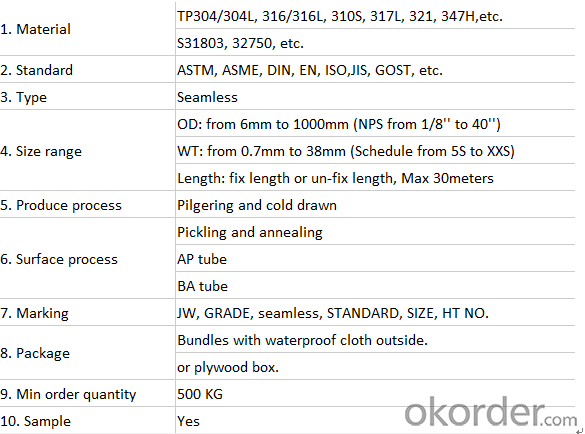

1,the desciption of the hot sell stainless steel pipe

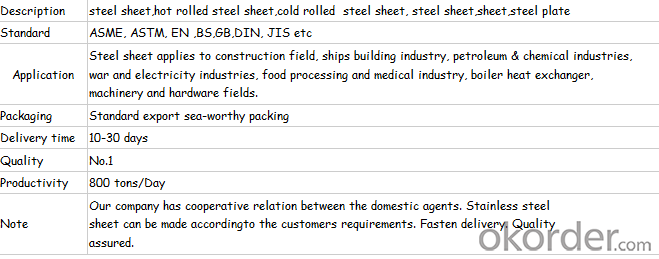

2,the application of the hot sell stainelss steel 304 201 stainless steel pipe

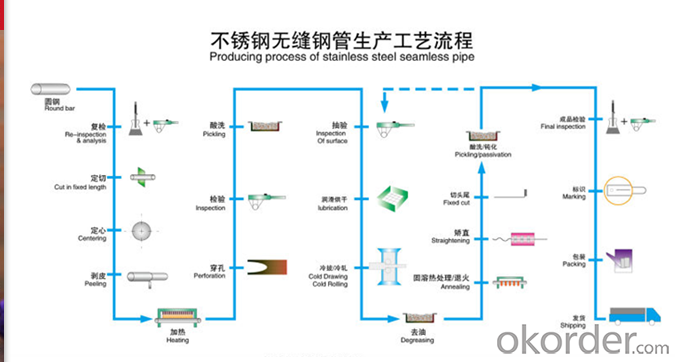

3,the producing procedure

4,related products show

5,FAQ

Q: WHAT ARE YOUR ADVANTAGES?

A: 1. We have a specialized team in dealing with all the documents required by customers. We aim to zero error to save money and time for client. 2. We have a strict quality control from production to delivery. 3. We take use of advanced system and tool to improve working efficiency and control every step. 4. Professional sales team to serve customers. 5. Samples can be provided as your requirements. 6. Professional packing team which keep every packing safely.

Q: WHAT ARE YOUR MAIN PRODUCT?

A: We are specializing in providing cold rolled 201/410/430 Stainless Steel Coil / Stainless Steel Strip / Stainless Steel Sheet / Stainless Steel Plate, Stainless Steel Circle, Stainless Steel tube / Stainless Steel Pipe Sheets.

Q: CAN I GET FREE SAMPLE?

A: YES. We can provide free sample. However, you should be responsible for the transportation freight. Please tell us your express account or please send us the transportation freight of samples firstly, then we can arrange sample delivery.

Q: HOW MUCH THE TRANSPORTATION FREIGHT WILL BE FOR THE SAMPLES?

A: The freight depends on the weight and packing size and your area.

- Q: Can stainless steel pipes be used for exhaust systems?

- Indeed, exhaust systems can utilize stainless steel pipes. Stainless steel, renowned for its exceptional resistance to both corrosion and heat, is a favored material for exhaust systems. It possesses the ability to withstand the severe temperatures and harsh circumstances to which exhaust systems are exposed, rendering it an enduring and long-lasting alternative. An added benefit of stainless steel pipes is their lightweight nature, which can enhance the performance of the exhaust system. Furthermore, stainless steel pipes can be effortlessly manipulated and molded, allowing for tailor-made adaptations to suit various vehicle models and configurations. All in all, stainless steel pipes present a dependable choice for exhaust systems, guaranteeing outstanding performance and longevity.

- Q: What is the difference between annealed and pickled stainless steel pipes?

- Annealed stainless steel pipes are heat-treated to remove internal stresses, making them softer and more malleable. This process improves their machinability and allows for easier forming and welding. On the other hand, pickled stainless steel pipes undergo a chemical treatment (usually with an acid solution) to remove surface impurities and oxide layers. This process enhances the corrosion resistance of the pipes and provides a smooth, clean surface finish.

- Q: Can stainless steel pipes be used for chemical pumps?

- Yes, stainless steel pipes can be used for chemical pumps. Stainless steel is known for its excellent corrosion resistance, making it suitable for handling various chemicals. It can withstand high temperatures and pressures, ensuring reliable performance in chemically aggressive environments. Stainless steel pipes are commonly used in chemical processing industries, wastewater treatment plants, and other applications involving the transfer of corrosive liquids or gases.

- Q: What are the common wall thicknesses for stainless steel pipes?

- The common wall thicknesses for stainless steel pipes vary depending on the specific application and industry standards. However, typical wall thicknesses for stainless steel pipes range from Schedule 5S (0.065 inches) to Schedule 80S (0.500 inches) in commercial and industrial settings.

- Q: Are stainless steel pipes suitable for pulp and paper mills?

- Absolutely, pulp and paper mills can definitely rely on stainless steel pipes. Stainless steel pipes possess a plethora of advantages that render them perfect for utilization in this particular sector. Firstly, stainless steel is remarkably resistant to corrosion and can endure the harsh chemicals and high temperatures commonly encountered in pulp and paper mills. This corrosion resistance guarantees that these pipes will have a lengthier lifespan, necessitating less maintenance and reducing downtime and costs linked with repairs or replacements. Furthermore, stainless steel pipes are acknowledged for their robustness and durability. They can handle high-pressure circumstances, ensuring a dependable and efficient flow of materials throughout the mill. This is especially crucial in pulp and paper mills where substantial volumes of water, chemicals, and pulp need to be transported. Additionally, stainless steel pipes are hygienic and effortless to clean, rendering them well-suited for applications in the pulp and paper industry that demand meticulous cleanliness standards. The smooth surface of stainless steel pipes also diminishes the likelihood of contamination and guarantees a seamless flow of materials, averting any blockages or clogs that could impede production. To conclude, due to their corrosion resistance, durability, strength, and ease of cleaning, stainless steel pipes are undeniably appropriate for pulp and paper mills. They provide a reliable and efficient solution for transporting materials, thereby facilitating the smooth operation of the mill and minimizing maintenance requirements.

- Q: Can stainless steel pipes be used for sewage and wastewater systems?

- Indeed, sewage and wastewater systems can make use of stainless steel pipes. Stainless steel is renowned for its exceptional resistance to corrosion, rendering it highly suitable for water and sewage-related purposes. Its ability to withstand rust, corrosion, and chemical reactions ensures an extended lifespan while reducing the necessity for frequent replacements. Moreover, stainless steel pipes possess a smooth surface that hinders the accumulation of debris and facilitates effortless cleaning. Furthermore, stainless steel is impermeable, preventing the growth of harmful bacteria and fungi, thus contributing to its hygienic nature and suitability for sewage and wastewater systems. The durability, dependability, and capacity to withstand harsh environmental conditions make stainless steel pipes a favored choice for such applications.

- Q: Are stainless steel pipes suitable for mining applications?

- Yes, stainless steel pipes are suitable for mining applications due to their excellent corrosion resistance, high strength, and durability. They can withstand harsh environments, extreme temperatures, and the corrosive nature of mining fluids, making them ideal for transporting and distributing various materials in the mining industry.

- Q: What is the maximum pressure rating for stainless steel pipe fittings?

- The maximum pressure rating for stainless steel pipe fittings varies depending on several factors such as the material grade, size, and temperature. Generally, stainless steel pipe fittings can handle high-pressure applications due to their inherent strength and corrosion resistance. The pressure rating of these fittings can range from 150 psi (pounds per square inch) to as high as 10,000 psi, depending on the specific fitting and its intended use. It is essential to consult the manufacturer's documentation or industry standards such as ASME B16.11 or ASME B16.9 to determine the maximum pressure rating for a specific stainless steel pipe fitting. Additionally, it is crucial to consider other factors such as the type of sealing method used, compatibility with the fluid being conveyed, and any additional safety measures required in high-pressure systems.

- Q: What is the difference between electropolished and bright annealed stainless steel pipes?

- Electropolished stainless steel pipes undergo a process called electropolishing, which involves the removal of surface impurities and oxidation through an electrochemical process. This results in a smooth, shiny, and corrosion-resistant surface finish. On the other hand, bright annealed stainless steel pipes are heat-treated to achieve a bright, reflective surface finish. While both processes enhance the aesthetics of the pipes, electropolishing provides additional benefits such as improved cleanability and increased resistance to corrosion.

- Q: Can stainless steel pipes be insulated with cellulose?

- Yes, stainless steel pipes can be insulated with cellulose. Cellulose insulation is a common choice for insulating pipes due to its high thermal resistance and fire-resistant properties. It can be used on various types of pipes, including stainless steel. Cellulose insulation can be applied to the pipes using different methods, such as wrapping the pipes with cellulose insulation blankets or filling the pipe cavities with loose-fill cellulose insulation. Insulating stainless steel pipes with cellulose can help prevent heat loss, reduce energy consumption, and ensure the pipes maintain a consistent temperature.

Send your message to us

CNBM hot sell 304,202 stainless steel pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords