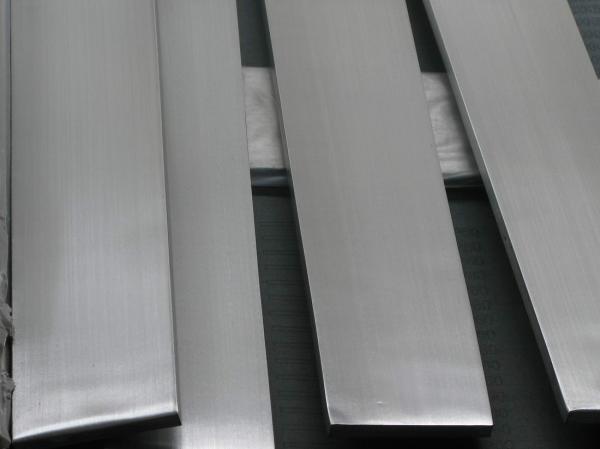

SUS 304 Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade:

1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. |

- Q: What is the difference between Schedule 20 and Schedule 40 stainless steel pipes?

- The wall thickness and pressure ratings distinguish Schedule 20 and Schedule 40 stainless steel pipes. Schedule 20 pipes, with their thinner walls, possess a greater internal diameter, facilitating a higher flow rate of liquids or gases. Ideal for residential plumbing or light-duty industrial applications, they suffice for lower pressure ratings. Conversely, Schedule 40 pipes boast thicker walls compared to Schedule 20 pipes. This increased thickness enhances their strength and durability, rendering them suitable for high-pressure applications in industries like oil and gas, chemical processing, or heavy-duty industrial processes. Regarding pressure ratings, Schedule 20 stainless steel pipes typically possess lower ratings than Schedule 40 pipes. This discrepancy arises from the thinner walls of Schedule 20 pipes, unable to withstand the same high pressure as their Schedule 40 counterparts. It is worth noting that both Schedule 20 and Schedule 40 stainless steel pipes share the same material, stainless steel. Their divergence lies solely in the wall thickness and consequent pressure ratings, enabling their suitability for distinct applications based on the required pressure and flow rate.

- Q: How do you connect stainless steel pipes?

- Stainless steel pipes can be connected using various methods such as welding, threading, and compression fittings. Welding is the most common method, where the pipes are joined together by heating and melting the metal at the joint, creating a strong and permanent bond. Threading involves screwing the pipes together using threads on the ends, while compression fittings use a nut and ferrule to compress and seal the pipes together. The choice of connection method depends on the specific application and requirements.

- Q: How do you calculate the expansion and contraction of stainless steel pipes?

- To calculate the expansion and contraction of stainless steel pipes, you need to consider the coefficient of thermal expansion for the specific grade of stainless steel being used. The coefficient of thermal expansion is a measure of how much a material expands or contracts in response to changes in temperature. First, determine the initial length of the stainless steel pipe, which is usually measured at room temperature. Then, determine the change in temperature that the pipe will be exposed to. The change in temperature is the difference between the maximum and minimum temperatures the pipe will experience. Next, multiply the initial length of the pipe by the coefficient of thermal expansion for the specific grade of stainless steel being used. The coefficient of thermal expansion for stainless steel can vary depending on the alloy and its composition, so it is important to consult the manufacturer's specifications or engineering references for the specific grade being used. Finally, multiply the result by the change in temperature to calculate the expansion or contraction of the stainless steel pipe. A positive value indicates expansion, while a negative value indicates contraction. It is important to note that the calculated expansion or contraction of the stainless steel pipe is an approximate value and can vary depending on various factors such as the specific alloy composition, manufacturing processes, and installation conditions. Therefore, it is recommended to consult with a qualified engineer or refer to industry standards for more accurate calculations in specific applications.

- Q: Can stainless steel pipes be used for steam transportation?

- Yes, stainless steel pipes can be used for steam transportation. Stainless steel has excellent corrosion resistance and high temperature strength, making it suitable for carrying steam under high pressure and temperature conditions. The smooth surface of stainless steel pipes also reduces friction and minimizes the risk of clogging or scaling, ensuring efficient and reliable steam transportation. Additionally, stainless steel is a durable material that can withstand extreme conditions, making it a preferred choice for steam transportation in various industries such as power generation, chemical processing, and oil and gas.

- Q: What is the maximum temperature stainless steel pipes can withstand?

- The specific grade of stainless steel used determines the maximum temperature that stainless steel pipes can tolerate. Typically, these pipes can withstand high temperatures between 1200°C and 1400°C (2200°F to 2550°F). However, it's essential to consider that the actual maximum temperature may differ due to factors like the stainless steel composition, the duration of exposure to high temperatures, and the presence of corrosive elements in the surroundings. To obtain precise temperature limits for a specific grade of stainless steel pipe, it is always advised to refer to the manufacturer's specifications or seek guidance from a professional engineer.

- Q: Are stainless steel pipes suitable for mining applications?

- Yes, stainless steel pipes are suitable for mining applications. Stainless steel is a durable and corrosion-resistant material that can withstand harsh and demanding environments commonly found in mining operations. It offers excellent resistance to corrosion, abrasion, and high temperatures, making it ideal for transporting various materials such as water, chemicals, and minerals in the mining industry. Stainless steel pipes are also known for their strength and ability to handle high-pressure conditions, which is crucial in mining applications. Additionally, stainless steel is non-reactive and does not release harmful substances into the materials being transported, ensuring the safety and purity of the mining processes. Overall, stainless steel pipes are a reliable and long-lasting choice for mining applications due to their durability, corrosion resistance, and ability to withstand extreme conditions.

- Q: What are the different types of stainless steel pipe end connections?

- There are several different types of stainless steel pipe end connections, each designed for specific applications and requirements. Some of the most common types include: 1. Threaded connections: This type of connection features threads on the inside or outside of the pipe end, allowing it to be screwed onto another threaded fitting or pipe. Threaded connections are typically used for low-pressure applications. 2. Socket-weld connections: In this type of connection, the pipe end is inserted into a socket or recess of a socket-weld fitting and then welded around the outside of the pipe. Socket-weld connections are suitable for high-pressure applications and are known for their strength and reliability. 3. Butt-weld connections: Butt-weld connections involve welding the pipe end directly to another pipe or fitting. They are commonly used in high-pressure and high-temperature applications. 4. Flanged connections: Flanged connections feature a flange on the pipe end, which is then bolted to a mating flange on another pipe or fitting. Flanged connections are used in applications requiring easy disassembly or where there is a need for frequent maintenance. 5. Compression connections: Compression connections involve using a compression fitting to join the pipe ends. These connections are commonly used in plumbing and gas supply systems and are known for their ease of installation. 6. Grooved connections: Grooved connections involve using grooved couplings to join the pipe ends. These connections are often used in fire protection systems and are known for their quick and simple installation. Overall, the choice of stainless steel pipe end connection depends on the specific application, pressure requirements, ease of installation, and maintenance considerations. It is important to consult with a professional or refer to industry standards to determine the most suitable connection type for your particular needs.

- Q: Are stainless steel pipes suitable for brewery applications?

- Stainless steel pipes prove to be highly suitable for brewery applications with their exceptional corrosion resistance, durability, and hygienic properties, making them the preferred material in the brewing industry. These pipes can endure the challenging conditions of a brewery environment, including exposure to hot liquids and cleaning chemicals, without succumbing to corrosion or contaminating the beer. Furthermore, the smooth surface of stainless steel pipes aids in preventing the accumulation of bacteria and other impurities, ensuring a superior level of cleanliness and quality throughout the brewing process. Moreover, stainless steel is effortlessly cleaned and maintained, adding to its practicality for breweries. In conclusion, stainless steel pipes are a dependable and efficient choice for brewery applications.

- Q: What are the common applications for stainless steel pipes?

- Stainless steel pipes have a wide range of applications due to their unique properties and versatility. Some of the common applications for stainless steel pipes include: 1. Plumbing and water supply systems: Stainless steel pipes are commonly used in plumbing and water supply systems due to their corrosion resistance and ability to withstand high pressure. They provide a reliable and long-lasting solution for transporting water and other fluids. 2. Oil and gas industry: Stainless steel pipes are extensively used in the oil and gas industry for transporting oil, gas, and other hydrocarbons. They can withstand high temperatures and pressures, making them suitable for exploration, production, and transportation of these resources. 3. Food and beverage industry: Stainless steel pipes are widely used in the food and beverage industry due to their hygienic properties and resistance to corrosion. They are commonly used for transporting liquids, such as milk, juices, and processed foods, ensuring the safety and quality of the products. 4. Chemical and pharmaceutical industry: Stainless steel pipes are highly resistant to corrosion, making them ideal for the chemical and pharmaceutical industry. They are used for transporting various chemicals, acids, and solvents, ensuring the integrity of the substances being transported. 5. Construction and architecture: Stainless steel pipes are used in construction and architectural applications due to their aesthetic appeal and structural strength. They are often used for handrails, balustrades, structural columns, and decorative applications, adding a modern and sleek look to buildings. 6. Automotive industry: Stainless steel pipes are utilized in the automotive industry for exhaust systems due to their heat resistance and durability. They can withstand high temperatures and corrosive gases, ensuring the efficient operation of the exhaust system. 7. Power generation: Stainless steel pipes are used in power plants for transporting steam, water, and other fluids. They are resistant to high temperatures and pressures, making them suitable for power generation applications. 8. Aerospace industry: Stainless steel pipes are utilized in the aerospace industry for various applications, including aircraft exhaust systems, hydraulic systems, and fuel lines. They offer high strength-to-weight ratio, corrosion resistance, and reliability, meeting the stringent requirements of the aerospace industry. In summary, stainless steel pipes find applications in various industries due to their corrosion resistance, durability, and versatility. They are used in plumbing, oil and gas, food and beverage, chemical and pharmaceutical, construction, automotive, power generation, and aerospace industries, among others.

- Q: What are the different grades of stainless steel used for pipes?

- There are several different grades of stainless steel that are commonly used for pipes, each with their own unique properties and characteristics. The most common grades include: 1. Grade 304: This is the most widely used stainless steel grade for pipes. It offers excellent corrosion resistance, high-temperature strength, and good formability. It is commonly used for both indoor and outdoor applications, such as water supply pipes, food processing equipment, and architectural structures. 2. Grade 316: This grade is similar to 304 but contains a higher content of molybdenum, which enhances its corrosion resistance, especially against chlorides and other corrosive chemicals. It is commonly used in marine environments, chemical processing plants, and medical equipment. 3. Grade 321: This grade contains titanium, which stabilizes it against sensitization during welding or high-temperature exposure. It offers excellent resistance to oxidation and can be used in applications where high temperatures are involved, such as exhaust systems and boilers. 4. Grade 409: This grade is commonly used for pipes in automotive exhaust systems due to its excellent heat resistance and durability. It is also resistant to corrosion from road salts and other harsh chemicals. 5. Grade 347: Similar to grade 321, this grade contains niobium, which provides additional stabilization against sensitization. It is commonly used in high-temperature applications where resistance to intergranular corrosion is required, such as in aircraft and jet engine components. These are just a few examples of the different grades of stainless steel used for pipes. The specific grade chosen for a particular application depends on factors such as the environment, temperature, corrosion resistance requirements, and mechanical properties needed.

Send your message to us

SUS 304 Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords